Dimer acid modified alkyd resin and preparing method thereof

A technology of alkyd resin and manufacturing method, applied in the direction of polyester paint, coating, etc., can solve the problems of general dryness of paint, increase of product cost, etc., and achieve the effect of increasing average functionality, product performance, and drying speed

Inactive Publication Date: 2010-11-24

福建豪迪涂料科技股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The usual alkyd resins are made by polymerizing vegetable oil or vegetable oleic acid with polyols and polyacids. The prepared coatings are generally dry. In recent years, in order to meet different performance requirements, many modified alkyd resin products have appeared, mainly including TDI (toluene diisocyanate), styrene, acrylic modified alkyd resin, such as "Modern Paint and Coating" 2002 03 issue discloses a kind of manufacture method of TDI modified alkyd resin, "Chemical Engineering" 2001 01 Issue, "Material Protection" 2000 08 and "Chemical Technology and Development" 2006 Volume 35 Issue 5 disclosed the production method of styrene-modified alkyd resin, "Journal of South China University of Technology" (Natural Science Edition) 2000 Issue 08 disclosed a method for synthesizing acrylic modified alkyd resin, etc. The dryness of the paint formulated with the modified alkyd resin synthesized by the above method is improved, but the product cost is increased to varying degrees

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

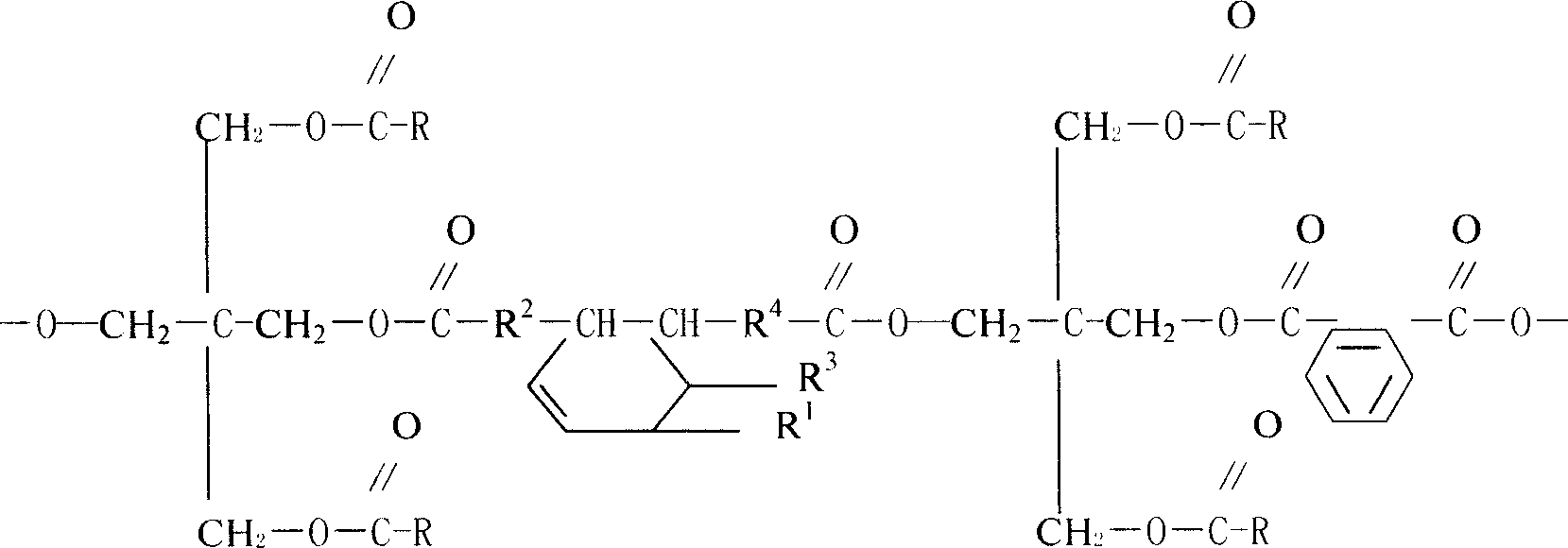

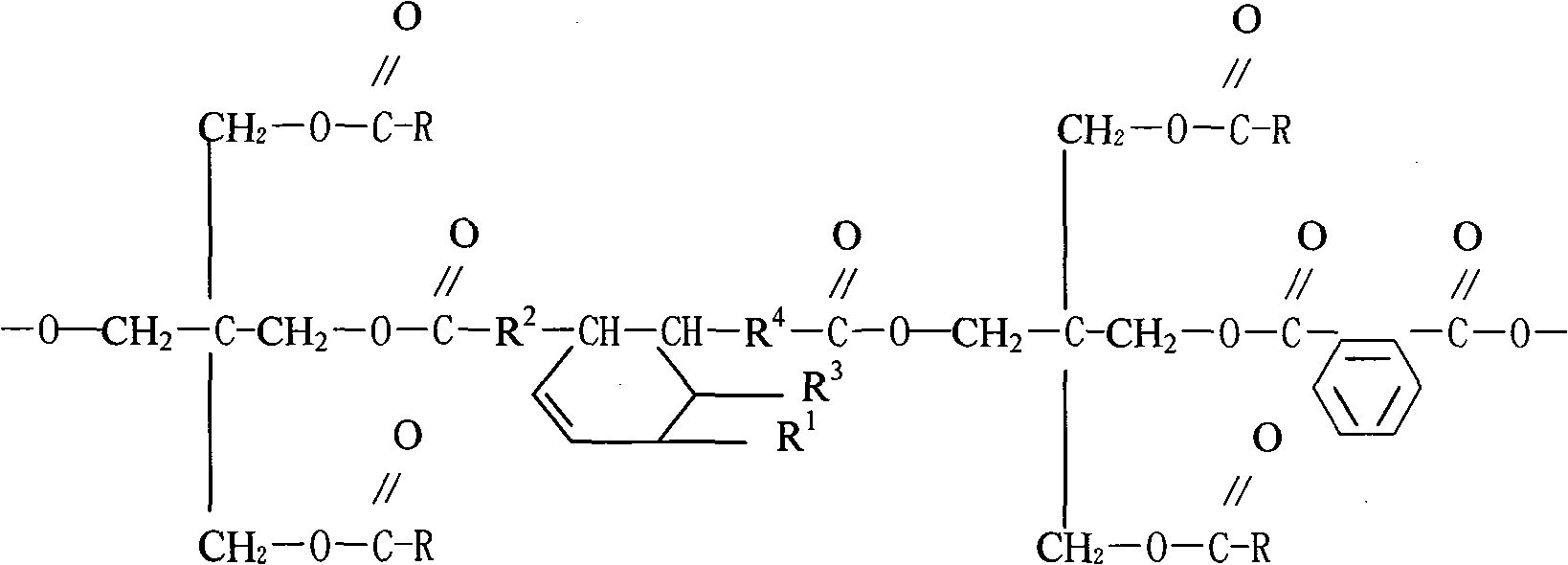

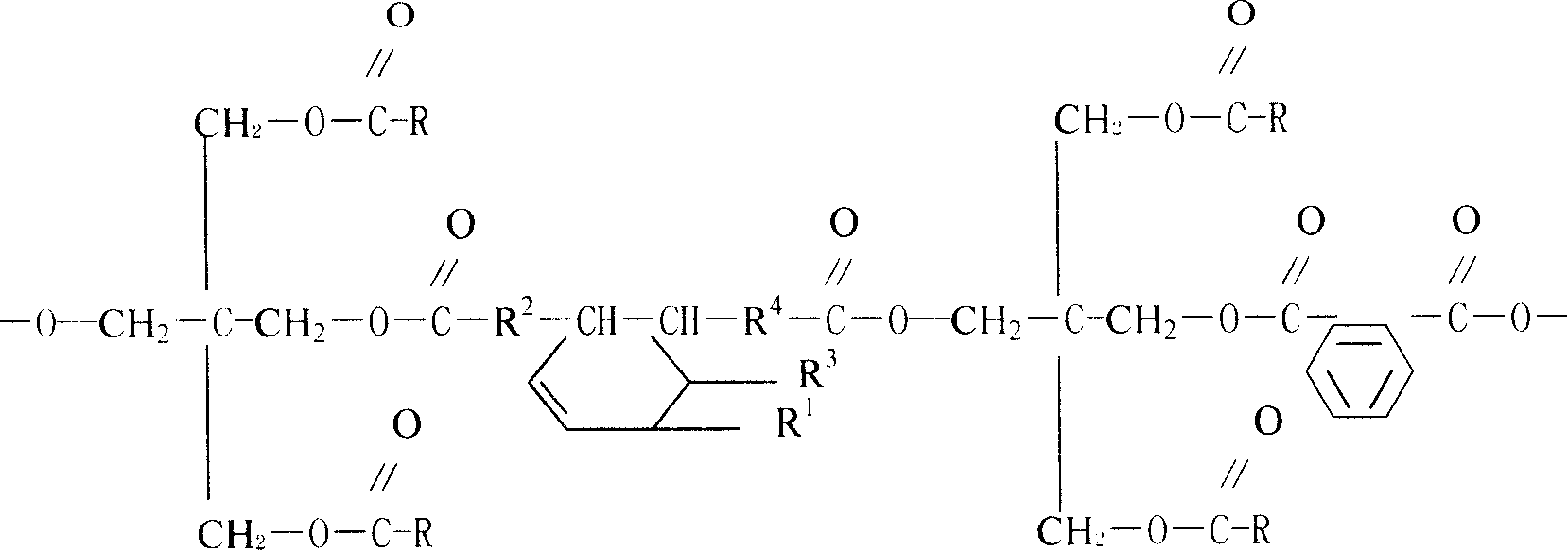

The invention discloses a modified alcohol acid resin (R is aliphatic acid hydrocarbyl group; R1, R2, R3 and R4 are dimer acid hydrocarbyl group or hydrocarbyl chain) and making method of paint coating, which comprises the following steps: adopting plant oleic acid as raw material; using dimer acid manufactured by plant oleic acid to replace oleic acid; making polyol, polyacid, reflux solvent anddilute solvent as auxiliary material to synthesize the product.

Description

Dimer acid modified alkyd resin and manufacturing method thereof 1. Technical field The invention belongs to a coating semi-finished product and a manufacturing method thereof in the technical field of fine chemicals, and in particular relates to a modified alkyd resin and a manufacturing method thereof. 2. Background technology The usual alkyd resins are made by polymerizing vegetable oil or vegetable oleic acid with polyols and polyacids. The prepared coatings are generally dry. In recent years, in order to meet different performance requirements, many modified alkyd resin products have appeared, mainly including TDI (toluene diisocyanate), styrene, acrylic modified alkyd resin, such as "Modern Paint and Coating" 2002 03 issue discloses a kind of manufacture method of TDI modified alkyd resin, "Chemical Engineering" 2001 01 Issue, "Material Protection" 2000 08 and "Chemical Technology and Development" 2006 Volume 35 Issue 5 disclosed the production method of styrene-modi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G63/49C09D167/08

Inventor 沈净李望

Owner 福建豪迪涂料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com