Overturning folding rail for receiving hot cell

A track and heat chamber technology, which is applied in the field of track transportation, can solve the problems such as the decline of the airtightness function index of radiation protection, and achieve the effect of good technological innovation, ensuring the use of space, and optimizing the protection of ionizing radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

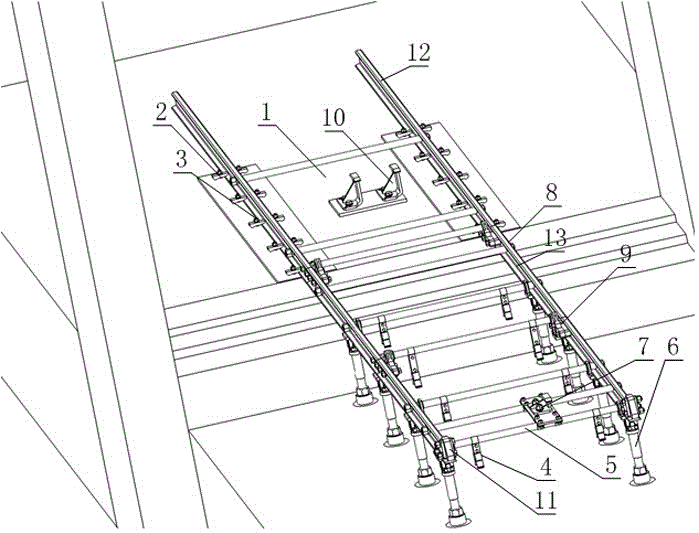

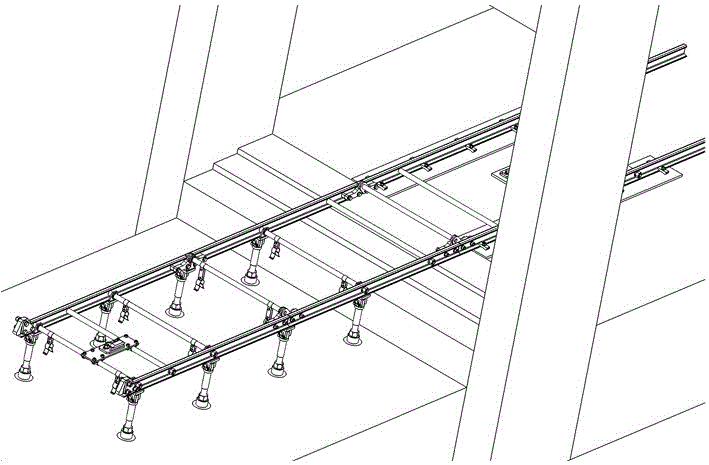

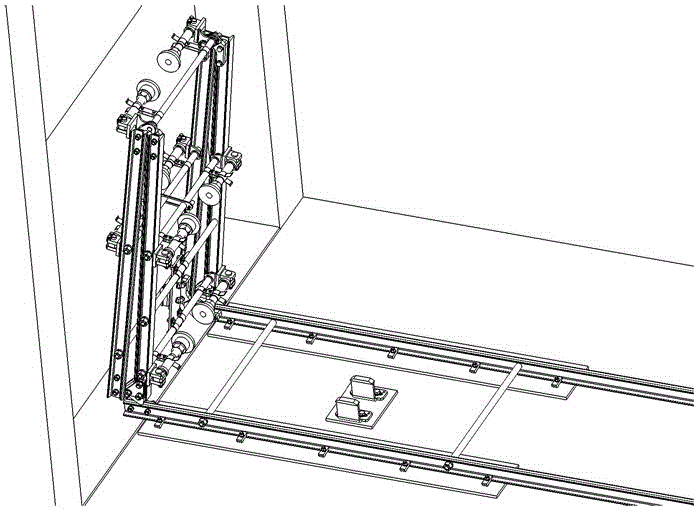

[0032] Such as figure 1 with 2 As shown, an overturning and folding track for a heat receiving chamber includes a track body on which a steel rail for a traveling vehicle is provided. The track body includes a fixed track portion 12 and an overturned track portion 13. The fixed track The portion 12 and the turning rail portion 13 are hingedly connected by a first hinge shaft 8, and the steel rail includes a first steel rail provided on the fixed rail portion 12 and a second steel rail provided on the turning rail portion 13;

[0033] The fixed rail part 12 is further provided with a fixing part, and the fixing part is used to fix the fixed connection between the rail part 12 and the surface of the heating chamber and / or the accessories in the heating chamber;

[0034] The turning rail portion 13 is further provided with a leg 6 which is used for supporting the turning rail portion 13 in the use state of the turning and folding track.

[0035] In this embodiment, one side of the fixed...

Embodiment 2

[0040] This embodiment is further limited on the basis of embodiment 1, such as figure 1 with 2 As shown, as a specific implementation form of the fixing part, the fixing part includes a backing plate 1, a connecting bolt 3, and a pressure block 2. The pressure block 2 is bolted to the backing plate 1 by a connecting bolt 3, and the first rail The compressive stress provided by the pressing block 2 is fixed on the backing plate 1. In the above implementation form, the backing plate 1 can be fixed on the bottom surface of the cement floor of the heating chamber by anchor bolts or ground anchors, or fixed on the stainless steel cladding surface of stainless steel by welding connection, and the second is realized by connecting bolts 3 and pressing blocks 2. The fixing of a steel rail on the backing plate 1 facilitates the formation of a detachable connection form between the first steel rail and the backing plate 1. In order to facilitate compaction and fixation, the first steel ra...

Embodiment 3

[0048] This embodiment is further limited on the basis of any one of the technical solutions provided by any of the above embodiments, such as Figure 1 to Figure 3 As shown, as a technical solution that facilitates the smooth movement of the vehicle on the flip-folded track and does not require an excessively wide track surface of a single rail, there are two rails, and the two rails are parallel to each other, and the two first rails are both fixed It is connected to the fixed part and further includes a connecting rod 5 arranged between the two second steel rails, and different ends of the connecting rod 5 are respectively fixedly connected to different second steel rails.

[0049] In order to facilitate the vehicle to leave or drive onto the inverted and folded track, the free end of the second steel rail is also provided with an inclined rail 11 whose track surface is an inclined surface. The free ends of the two steel rails are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com