Quantitative rock soil ore loading station

A technology for loading stations and ores, which is applied in the directions of transportation, packaging, loading/unloading, etc., which can solve the problems of easy jamming of the batching gate, wear of the inclined wall of the warehouse, and damage to the bottom of the wagon, so as to avoid uneven loading , Uniform cloth, solve the effect of rapid wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

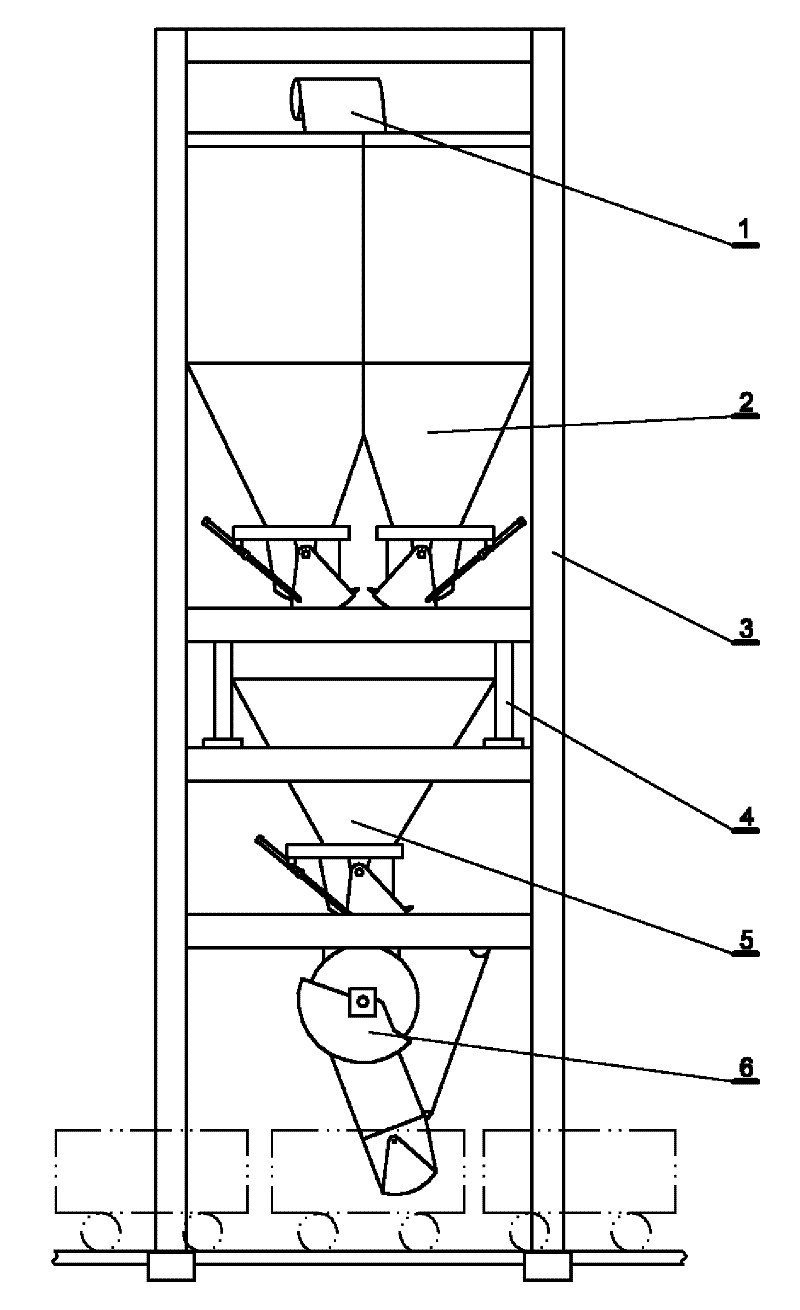

[0012] This embodiment is a quantitative loading station for rock and soil ore, such as figure 1 . The loading station described in this embodiment includes: a steel structure frame 3, the conveyor belt head 1 is installed on the uppermost end of the steel structure frame, and a swing arc gate is installed on the steel structure frame below the conveyor belt head The buffer warehouse 2, the bottom of the buffer warehouse is the quantitative warehouse 5 with a swing arc gate connected to the steel structure frame through the weighing device 4, and the belt mounted on the steel structure frame is installed under the quantitative warehouse. There is a swing chute 6 with an arc-shaped gate; the inner walls of the slanted silos of the buffer bins and quantitative bins are provided with anti-wear grids.

[0013] The loading station described in this embodiment is specially used for loading geotechnical ore. Geotechnical ore is characterized by higher hardness and larger particle s...

Embodiment 2

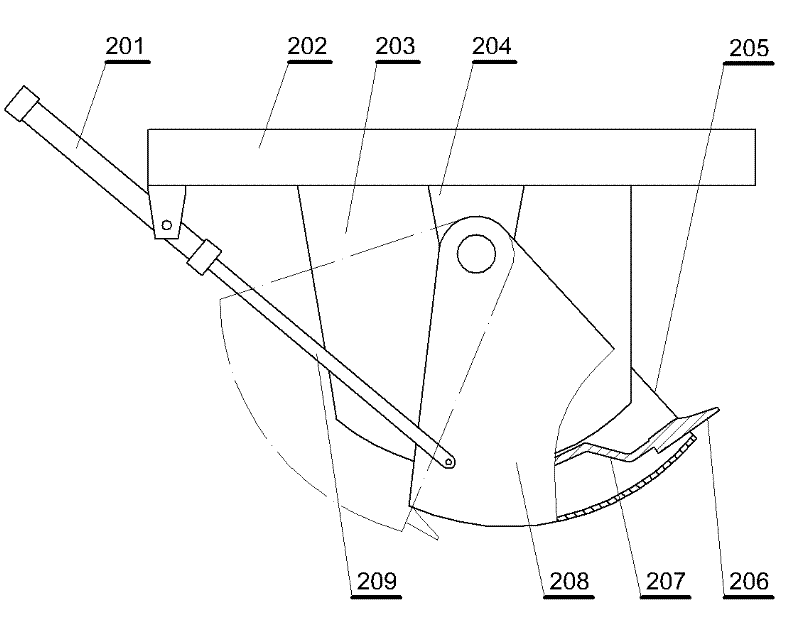

[0019] This embodiment is an improvement of Embodiment 1, and it is an improvement of Embodiment 1 about the swing arc gate, such as figure 2 shown. The swing arc gate described in this embodiment is a single-wing swing arc gate, comprising: a warehouse gate lifting lug 204 fixed on the warehouse body 202 of the buffer warehouse or quantitative warehouse, and the warehouse gate lifting lug can cover the buffer warehouse or The warehouse gate body hinge connection of the discharge port 203 of the quantitative warehouse, the warehouse gate body 208 is hingedly connected with the oil cylinder rod 209 of the warehouse gate opening and closing oil cylinder, and the cylinder body 201 of the warehouse gate opening and closing oil cylinder is hingedly connected with the warehouse body. The two sides of the warehouse gate body are triangular side plates, the bottom of the warehouse gate body is arc-shaped, the bottom of the warehouse gate body is close to the warehouse gate 205 and a ...

Embodiment 3

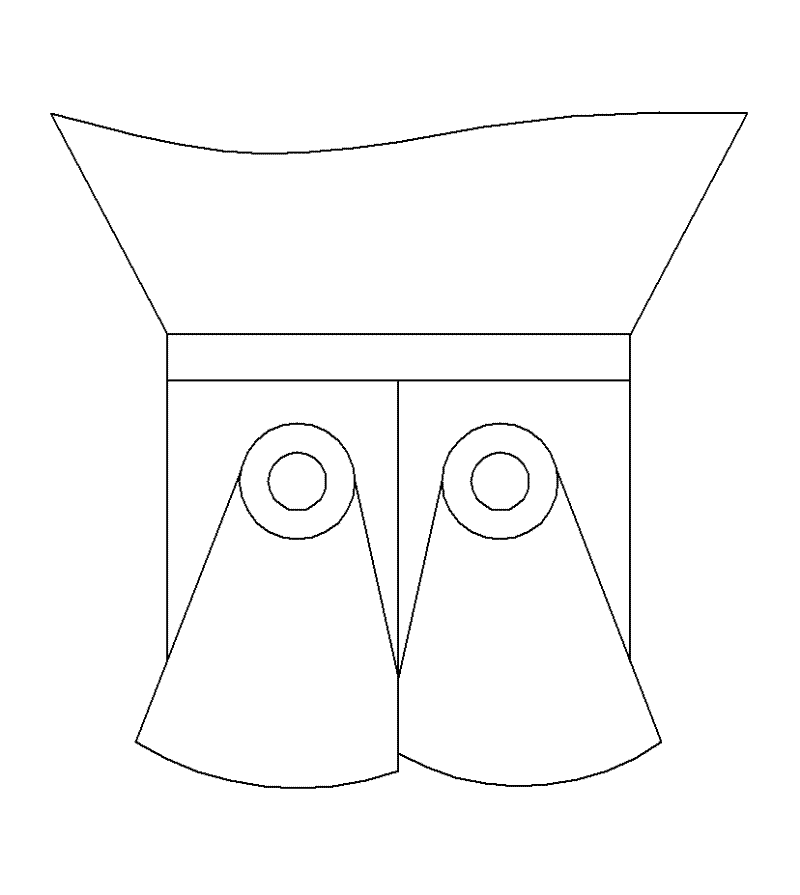

[0022] This embodiment is an improvement of Embodiment 1, and it is the refinement of Embodiment 1 on the swing arc gate, such as image 3 shown. The swing arc warehouse gate described in this embodiment is a swing arc gate with two wings.

[0023] There is not much difference in structure between the single-wing swing arc gate and the double-wing swing arc gate, except that the double-wing swing arc gate has an additional set of swing arc gates. The two sets of swing arc gates are left-right symmetrical and open symmetrically. The double-wing swing arc gate includes: the warehouse gate lifting lugs symmetrically fixed on the buffer warehouse or the quantitative warehouse body, and the symmetrical warehouse gate lifting lugs can cover the discharge port of the buffer warehouse or quantitative warehouse when combined with two The symmetrically installed warehouse door is hinged. The two warehouse gate bodies are respectively connected with the cylinder rod hinges of two symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com