Unit roll-disk breaker

A pulverizer and unit type technology, applied in the field of roller pulverizers, can solve the problems of high price, small pulverization ratio, troubled enterprises, etc., and achieve the effect of lower equipment price, lower manufacturing cost, and easy industrial manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

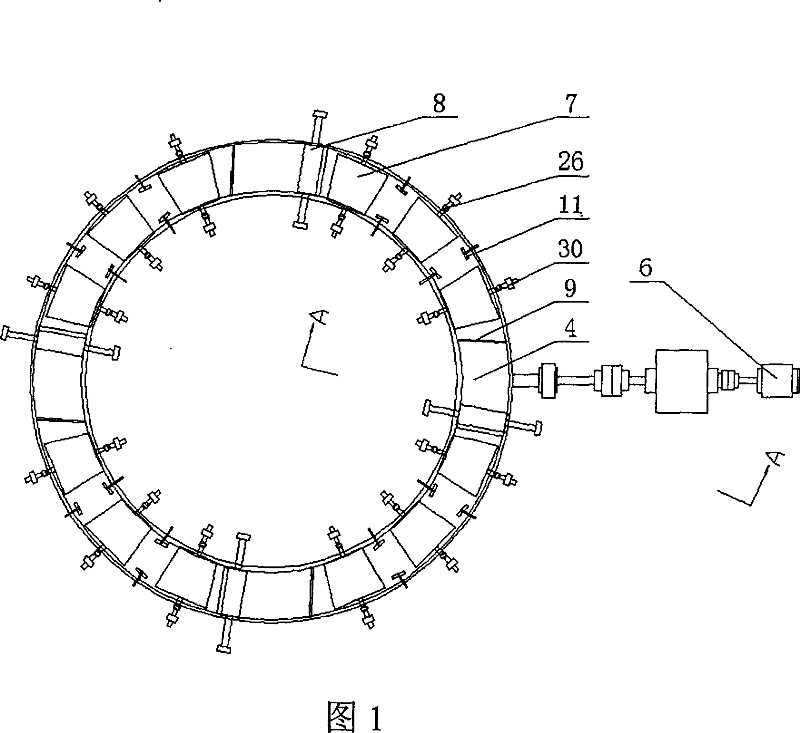

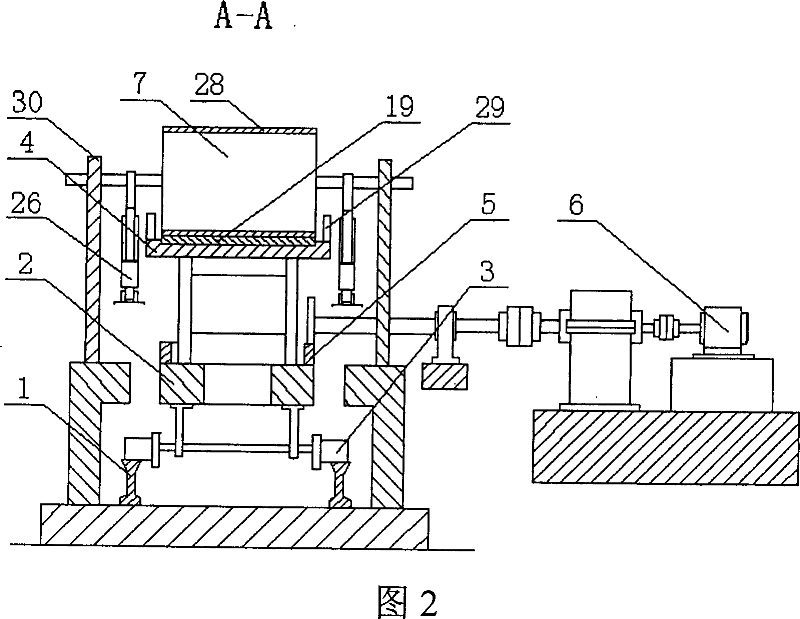

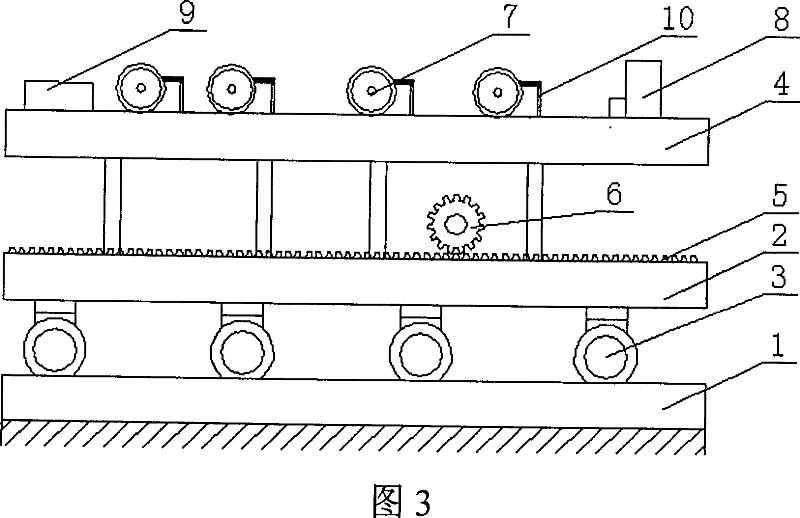

[0064] As shown in Figures 1-3, the unit type roller disc pulverizer of the present invention has an annular track 1, an annular flat car 2, an annular grinding disc 4, a roller 7, a hydraulic system 26 and a power unit 6.

[0065] The circular flat car 2 is arranged on the circular track 1, and the bottom of the circular flat car 2 is provided with wheels 3, and the wheels 3 are placed on the track 1. The top of the flat car 2 is embedded with an annular grinding disc 4 made of a wear-resistant flat liner 19 .

[0066]Fig. 6 and Fig. 7 have shown the alternative embodiment of above-mentioned structure, that is, also can adopt conventional annular plane bearing 20 or annular plane bearing bush 21 to replace the vehicle frame of annular flatbed vehicle 2, wheel 3 and annular track 1. When the annular plane bearing 20 is used, the annular mill plate 4 is placed directly on top of the annular plane bearing 20 . The annular plane bearing (20) used can be of ball type or roller ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com