Percussive hydraulic hammer drilling apparatus special for shale gas

A shale gas and percussion technology, which is applied to drilling equipment, driving devices for drilling in boreholes, earthwork drilling and production, etc. It can solve problems such as slow footage and drill bit wear, and achieve simplified structure, extended life, and increased drilling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

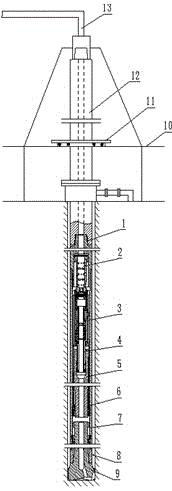

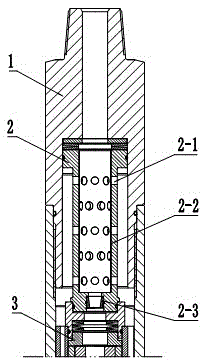

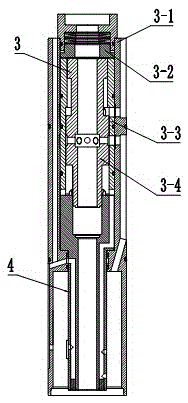

[0033] see figure 1 According to the present invention, the special impact hydraulic hammer drilling equipment for shale gas cooperates with the drilling platform 10, the drilling rig rotary table 11, the drill pipe 12 and the power fluid pipeline 13 in the ground power system to complete the shale gas drilling operation. The special impact hydraulic hammer drilling equipment for shale gas includes an upper joint 1, an outer casing 7, a shunt pipe 2, a valve chamber assembly 3, a special control pipe 4, a piston assembly, a lower joint 8 and a drill bit 9; the drill bit 9 A diamond drill bit with a gauge tooth structure is preferred. The drill bit 9 is arranged at the bottom of the wellbore, and is connected to the drill pipe 12 in the ground power system through the lower joint 8, the outer casing 7, and the upper joint 1. Driven by the rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com