Hydraulic lift dam

A technology of hydraulic lifting dam and hydraulic cylinder, applied in the field of hydraulic lifting dam, can solve the problems of low reliability and safety of hydraulic dam, water leakage of hydraulic dam, inability to achieve dam surface leveling, etc., so as to avoid water leakage at the bottom, installation and maintenance operations The effect of convenience, improved reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

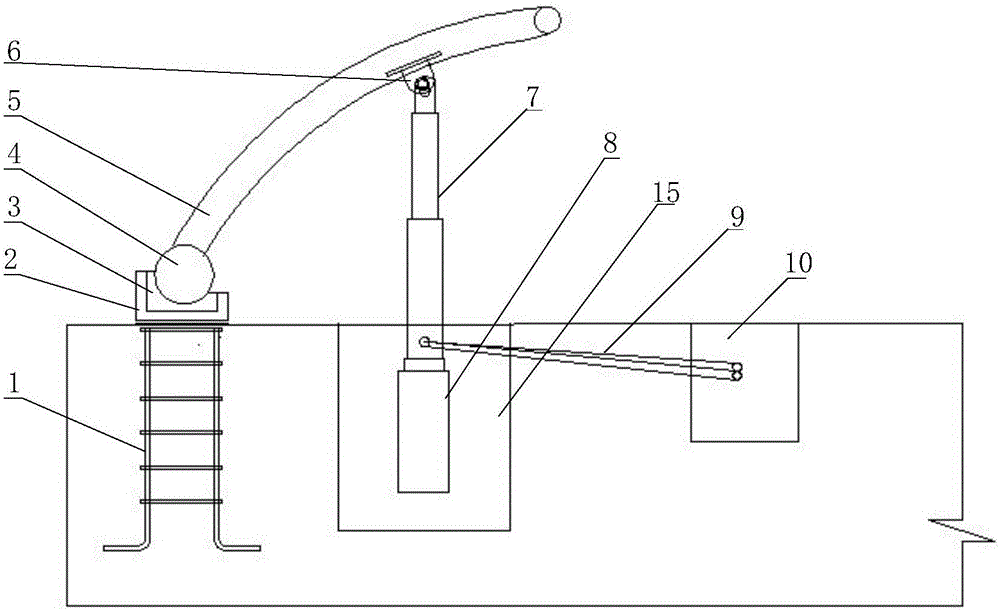

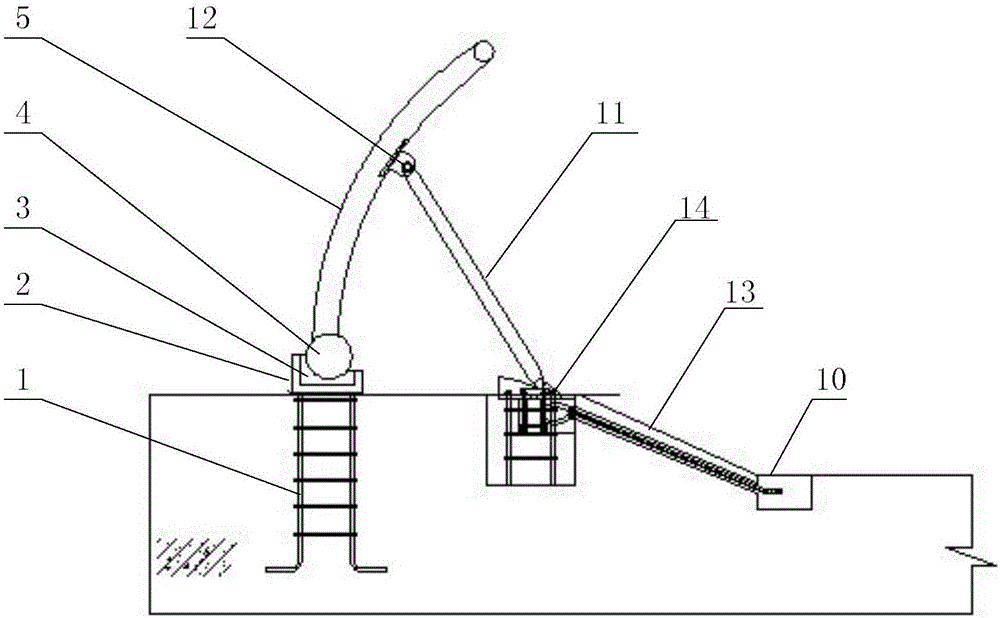

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0017] During specific implementation, combined with Figure 1-2 , a hydraulic lifting dam, including steel ground anchor 1, embedded steel channel 2, water-stop rubber 3, concentric shaft 4, movable plate 5, lug 6, hydraulic rod 7, hydraulic cylinder 8, oil pipe 9, hydraulic station 10. Support rod 11, lug 12, slideway 13, limit device 14, hydraulic cylinder groove 15.

[0018] A hydraulic lifting dam, the pre-embedded steel channel 2 is fixedly installed on the reinforced ground anchor 1, and the pre-embedded steel channel 2 can be fixed on the reinforced ground anchor 1 in the form of welding. The concentric shaft 4 is movably installed in the embedded steel channel 2. In order to avoid water leakage, a water-stop rubber 3 is installed betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com