Grouting pipeline structure, X-shaped special-shaped pile for prefabricating grouting pipeline and grouting method thereof

A technology of grouting pipes and special-shaped piles, which is applied in the field of geotechnical engineering, can solve problems such as adverse effects on engineering quality and safety, insufficient pile side friction resistance of X-shaped piles, and pile settlement, so as to improve the reserve of pile side friction resistance, Enhance adaptability and flexibility, improve the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

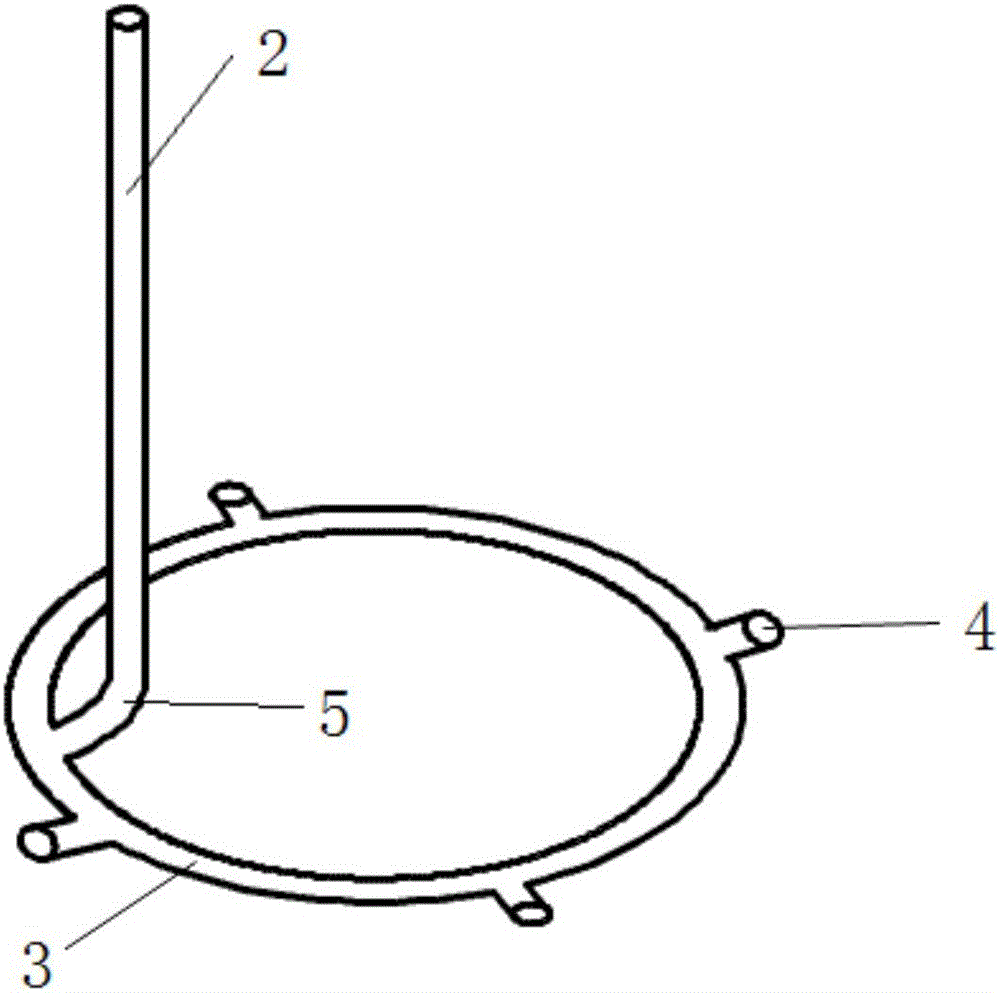

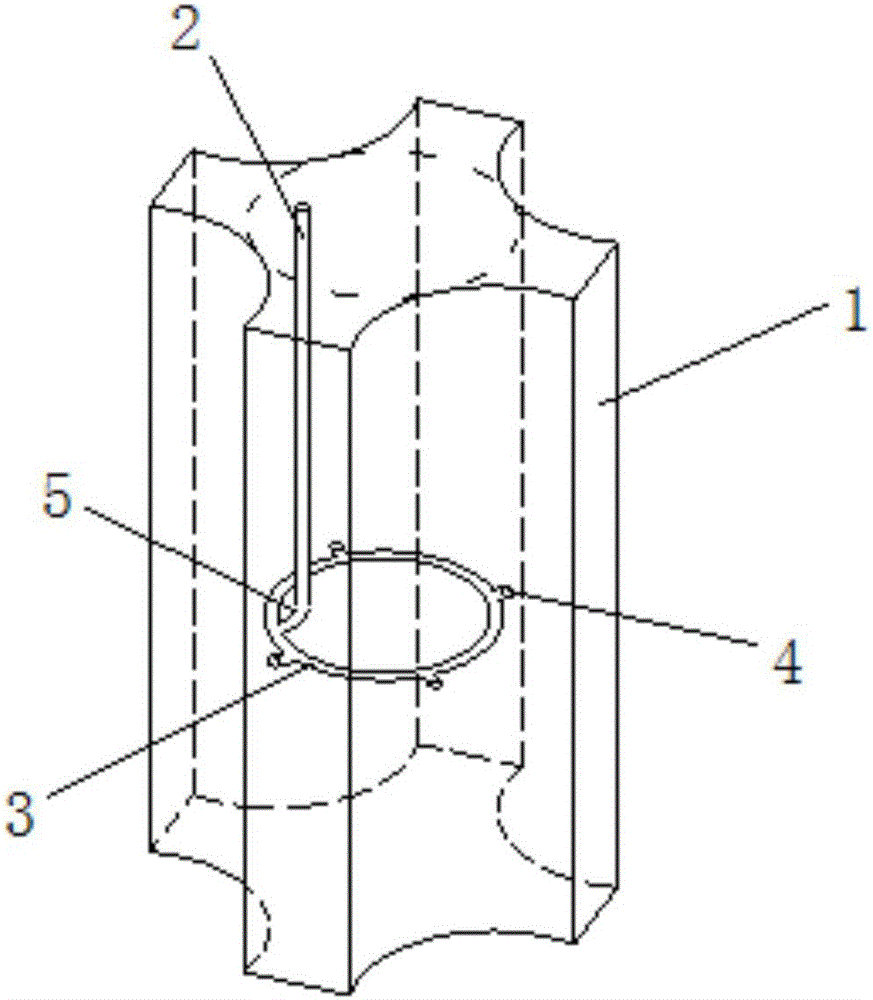

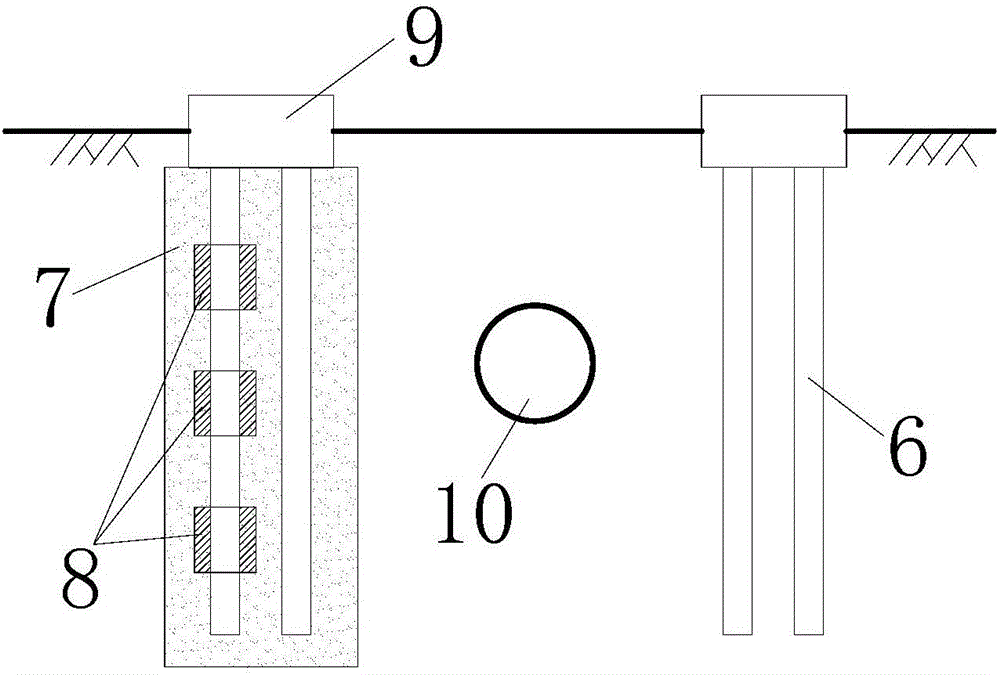

[0031] Such as figure 1 As shown, a grouting pipeline structure includes a longitudinal pipeline 2, an annular pipeline 3 and an overhanging pipeline 4; the overhanging pipeline 4 is drawn from the annular pipeline 3; the longitudinal pipeline 2 is arranged axially along the pile body , the annular pipeline 3 and the overhanging pipeline 4 are perpendicular to the longitudinal pipeline 2 in space;

[0032] The position of the annular pipeline 3 in the axial direction of the pile needs to be comprehensively determined in combination with the surrounding geological conditions and the size of the pile. An outreach pipeline 4 is provided at the place where the distance between the annular pipeline 3 and the side of the pile body is the smallest, and the overhang pipeline 4 is used as a slurry outlet to communicate with the outside world, and is ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com