An Angle Measuring Method for Construction Machinery

A technology for angle measurement and construction machinery, which is applied to mechanically driven excavators/dredgers, measuring devices, and electrical devices, and can solve problems such as easy damage to connecting rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

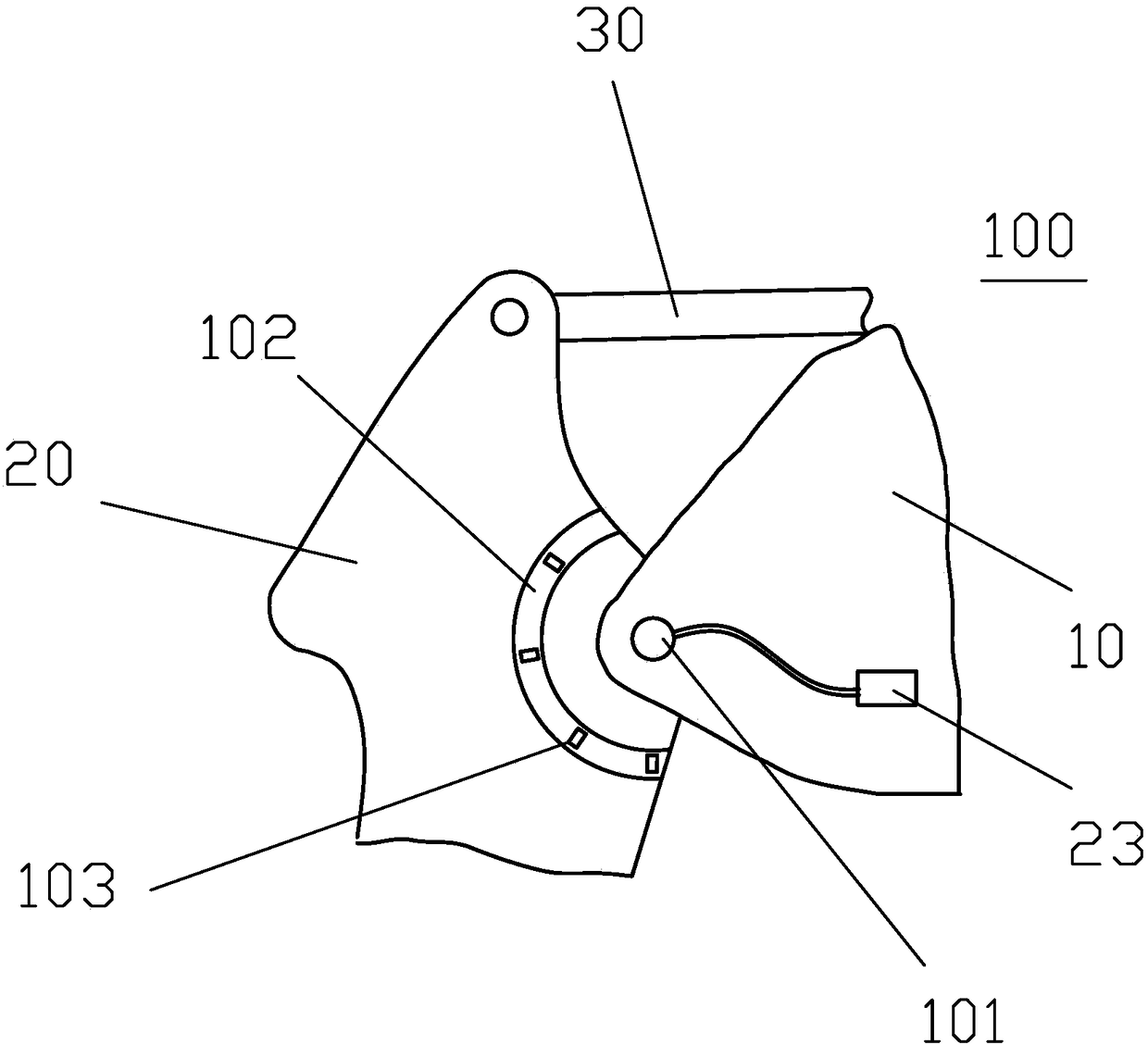

[0025] The present invention provides an angle sensor 100 for a construction machine, which is illustrated as an angle sensor installed between the boom 10 and the stick 20 .

[0026] During working, the arm 20 can pivot around the pin 101 of the boom 10 under the action of the hydraulic lever 30 . The angle measuring device 100 includes an arc-shaped annular magnet seat 102 , which is arranged on the stick 20 and distributed around the pin shaft 101 in a ring shape. Preferably, the annular magnet seat 102 is arranged inside the box-shaped structure of the stick 20 to protect the annular magnet seat 102 from collision damage during operation. However, the present invention is not limited thereto, and the annular magnet seat 102 can obviously also be arranged outside the stick 20 . Schematic figure 1 There is a relatively large distance between the middle annular magnet seat 102 and the pin shaft 101 , but the present invention does not limit the distance.

[0027] The end o...

Embodiment 2

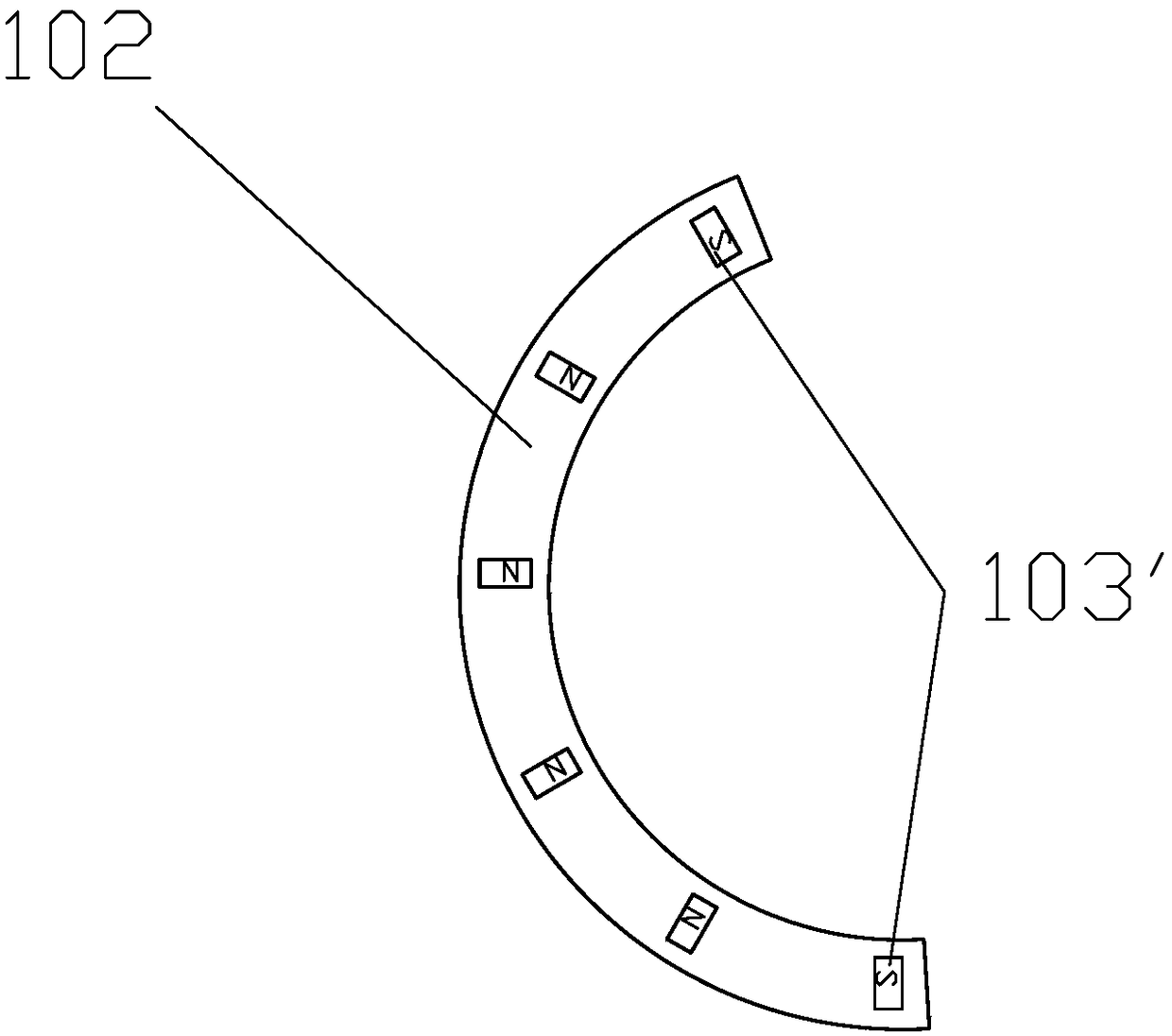

[0030] Preferably, the annular magnet base 102 includes a plurality of magnets 103 arranged around the pin shaft 101, so that the magnetic flux measured by the Hall effect sensor is more obvious. Such as figure 2 As shown, the magnetic poles of the magnets 103 arranged at the arc-shaped two ends of the ring-shaped magnet base 102 magnets are opposite to the other magnetic poles. In this way, when the arm rotates, when the magnetic field strength detected by the Hall effect sensor changes abruptly, it can Mutation of the trigger signal.

[0031] Preferably, the number of Hall switches arranged on the circuit board is n, and n is a natural number, which corresponds to the angle along the ring magnet base 102. Therefore, when the stick 10 rotates and triggers m switches, the circuit corresponds to Generate m fixed codes, each of which contains two sets of data (because only the magnetic poles of the magnets 103' at both ends are different), where m is less than n, and only need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com