Method for improving energy storage efficiency of compressed air energy storage system

A compressed air energy storage and system energy storage technology, which is applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of lack of grid-connected research, lack of theoretical analysis results, and restrictions on the development of compressed air energy storage systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

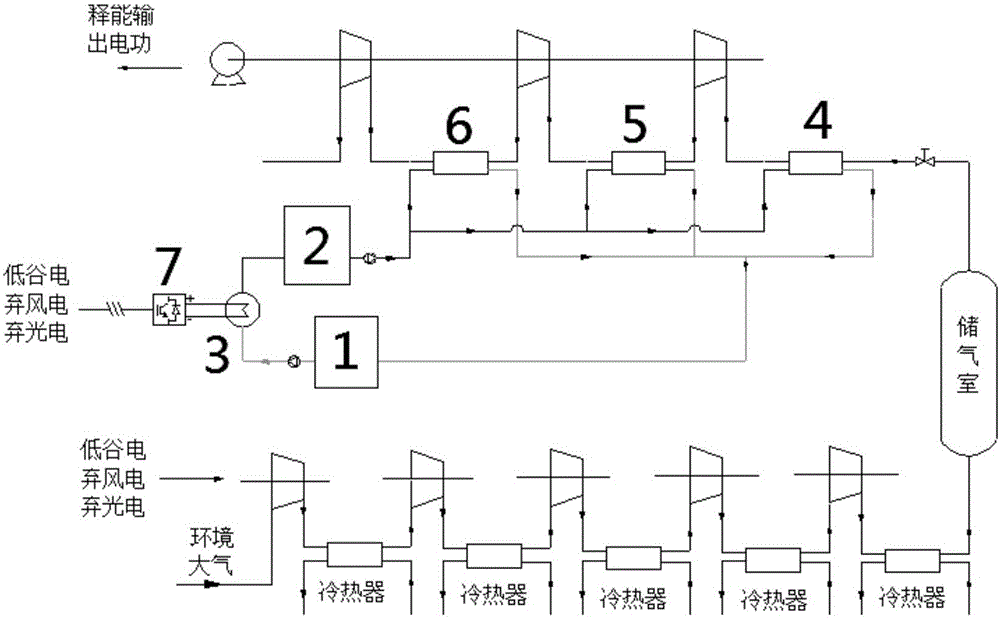

[0015] In order to optimize the energy storage efficiency of the system and explore a higher cycle flow, the present invention proposes a new compressed air energy storage flow. The process uses molten salt as the heat storage medium, which greatly improves the circulation parameters of the system.

[0016] Specific as figure 1 As shown, the present invention includes adding a low-temperature molten salt tank 1 to the existing energy storage system, and the low-temperature molten salt in the low-temperature molten salt tank 1 is heated by a molten salt electric heater 3 and then transported to a high-temperature molten salt tank 2; The high-temperature molten salt in the salt tank 2 returns to the low-temperature molten salt tank 1 after passing through the first-stage turbine heater 4 , the second-stage turbine heater 5 , and the third-stage turbine heater 6 . The low-peak power, abandoned wind power, and abandoned photovoltaics stored in the energy storage system supply pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com