Split-shaft type birotor wind power generation motor

A dual-rotor, split-shaft technology, used in wind turbines, wind energy power generation, and wind turbines in the same direction as the wind, can solve the problems of low power generation efficiency of wind power generators, and achieve the goal of improving power generation efficiency and electric energy conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

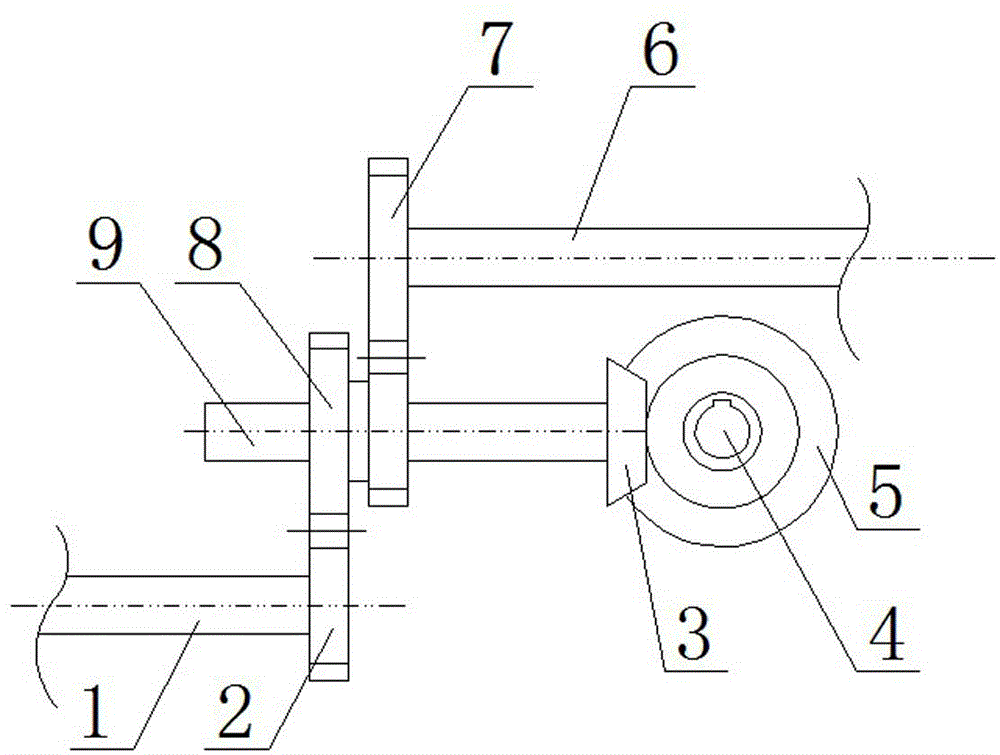

[0009] according to figure 1 The specific structure of the present invention will be described in detail. The split-shaft double-rotor wind power generator includes a blade shaft, blades arranged on the blade shaft, a generator shaft 4 perpendicular to the ground, a generator arranged on the ground and the like. Wherein, the wind blades include first wind blades and second wind blades (not shown in the figure) respectively arranged on the first wind blade shaft 1 and the second wind blade shaft 6, the first wind blade shaft 1, the second wind blade shaft The blade shafts are set in 6 sub-shafts and have the same rotation direction (which can be realized by the blade setting direction on the fan blade). The output end of the first fan shaft 1 is provided with a first gear 2, the output end of the second fan shaft 6 is provided with a second gear 7, the connecting shaft 9 is provided with a connecting gear 8, and the connecting gear 8 is provided with a Big and small two gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com