Controlled wedge block type bidirectional overrunning clutch

An overrunning clutch and wedge type technology, applied in the field of mechanical transmission, can solve the problems of inability to realize program controllability and poor versatility, and achieve the effects of compact structure, easy layout and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

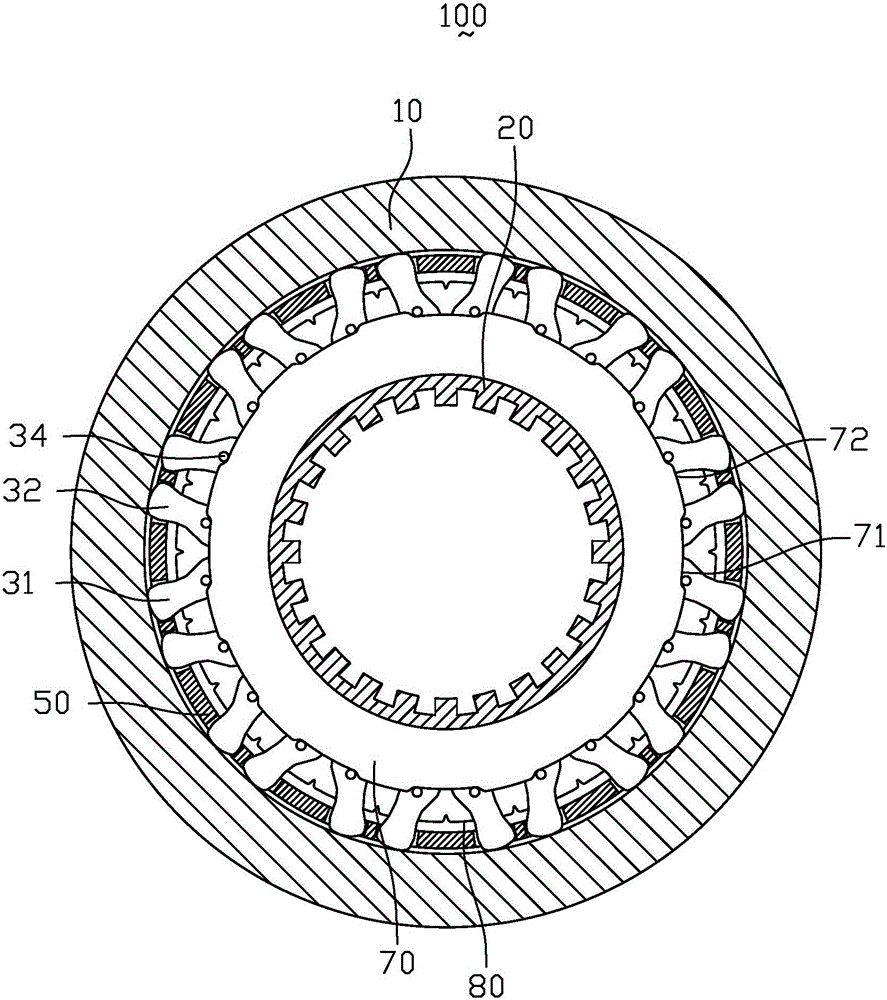

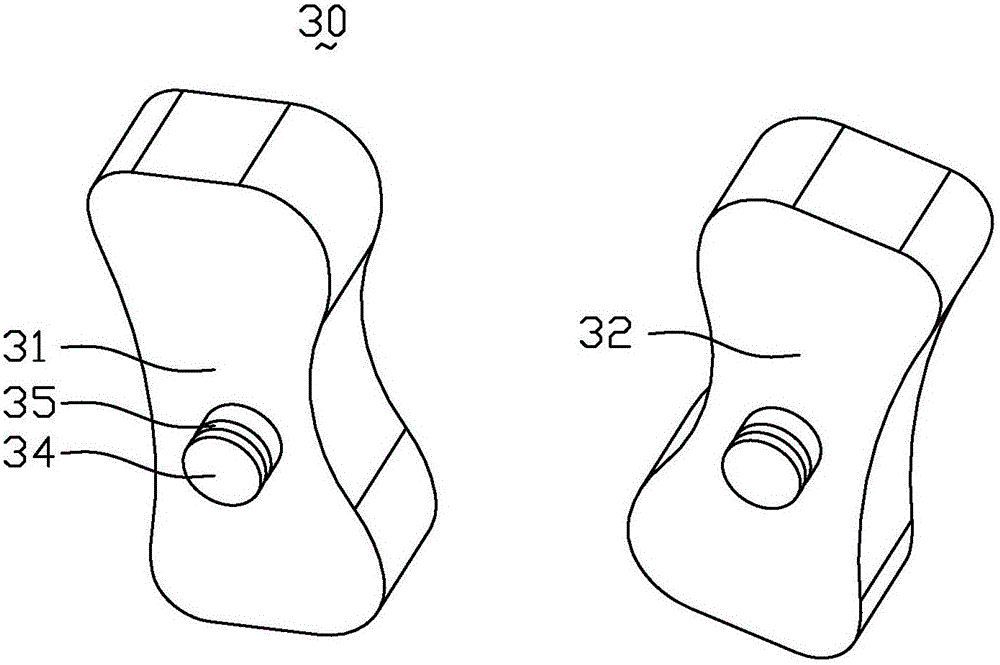

[0034] Please refer to figure 1 , figure 2 , this embodiment provides a controllable sprag type two-way overrunning clutch (hereinafter referred to as "overrunning clutch") 100, such as figure 1 and figure 2 As shown, the overrunning clutch 100 includes an outer ring 10, an inner ring 20, a plurality of counterclockwise sprags 31 located between the outer ring 10 and the inner ring 20, a plurality of clockwise sprags located between the outer ring 10 and the inner ring 20 The wedge 32, the cage 50 between the outer ring 10 and the inner ring 20 to hold the plurality of counterclockwise wedges 31 and the plurality of clockwise wedges 32, is used to control the plurality of counterclockwise wedges 31 and the plurality of clockwise wedges. A plurality of clockwise wedges 32 relatively rotate the control disk 70 .

[0035] The plurality of counterclockwise wedges 31 and the plurality of clockwise wedges 32 are oppositely arranged for realizing forward and reverse overrunning ...

no. 2 example

[0052] This embodiment is a modification of the first embodiment, and to avoid repetition, the same parts as the first embodiment are omitted here.

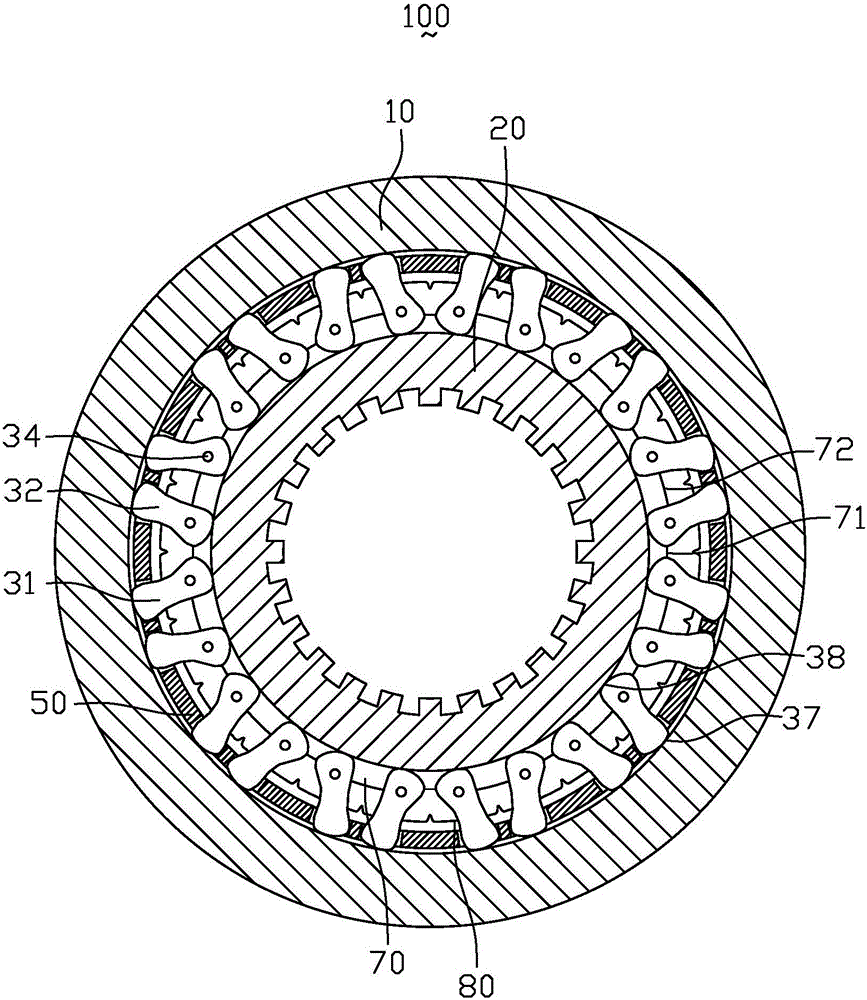

[0053] Please refer to Figure 11 ,Such as Figure 11 As shown, this embodiment provides a controllable sprag type two-way overrunning clutch (hereinafter referred to as "overrunning clutch") 100, the counterclockwise sprag 31 and the clockwise sprag 32 are arranged at intervals, and the number of the counterclockwise sprag 31 is the same as that of the clockwise sprag. The number of hour wedges 32 is different. In this embodiment, the number of counterclockwise wedges 31 is less than that of clockwise wedges 32 , and a plurality of clockwise wedges 32 are arranged between two adjacent counterclockwise wedges 31 . Or, in another embodiment, the number of clockwise wedges 32 is less than the number of counterclockwise wedges 31 , and multiple counterclockwise wedges 31 are arranged between two adjacent clockwise wedges 32 .

[...

no. 3 example

[0059] This embodiment is a modification of the first embodiment, and to avoid repetition, the same parts as the first embodiment are omitted here.

[0060] Please refer to Figure 12 ,Such as Figure 12 As shown, this embodiment provides a controllable sprag type two-way overrunning clutch 100, the counterclockwise sprag 31 and the clockwise sprag 32 are arranged side by side, and the counterclockwise sprag 31 is arranged continuously between the outer ring 10 and the inner ring 20 Clockwise wedges 32 are continuously arranged on another arc between the outer ring 10 and the inner ring 20 .

[0061] The outer edge of the control panel 70 is provided with grooves 71 and flanges 72, the grooves 71 and the flanges 72 are not equidistantly arranged, and the arrangement is determined according to the initial installation positions of the counterclockwise wedge 31 and the clockwise wedge 32 .

[0062] Other structures of the overrunning clutch 100 provided by this embodiment are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com