A car electronic gear selection mechanism

A technology for automotive electronics and electronic gear selection, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc. To achieve the effect of convenient fault handling, improved safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

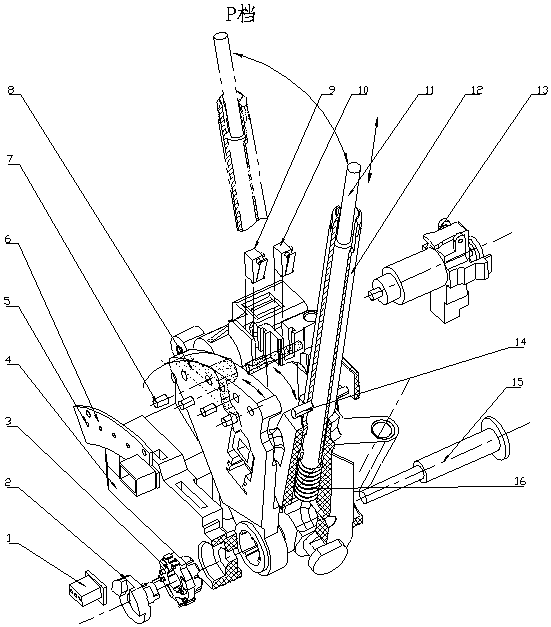

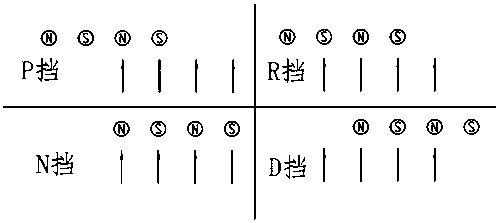

[0031] The optimal implementation mode: if figure 1 As shown, an automobile shifting device includes an electronic gear selection mechanism. The electronic gear selection mechanism includes a mounting base 4 on which a shifting power input member is installed, and the shifting power input member is rotatably installed by a rotating shaft 15. Fitted on the mounting base, each gear is set within the range of rotation of the shifting power input member so that the gear can be replaced by the rotation of the shifting power input member. A plurality of signal sensing and collecting components 5, and signal sensing components 7 corresponding to the signal sensing and collecting components 5, the signal sensing components are relatively fixed on the shift power input component or the mounting seat, and the signal sensing components When the gear shifting power input member rotates and shifts gears, it can enter the sensing range of the signal sensing and collecting member to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com