Multi-stage single-dual-control flow regulation switch valve

A technology of flow regulation and single/double control, which is applied in the field of bathroom industry, can solve the problems of missing flow regulation parts, incapable flow regulation or combined regulation, etc., and achieve the effect of improving hand feeling, simple structure and not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

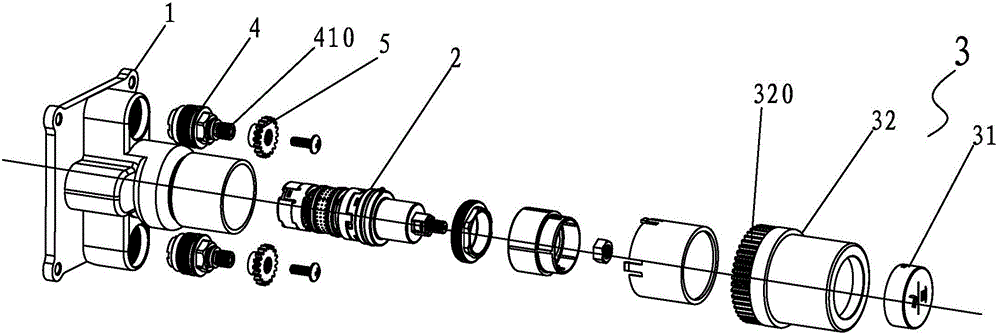

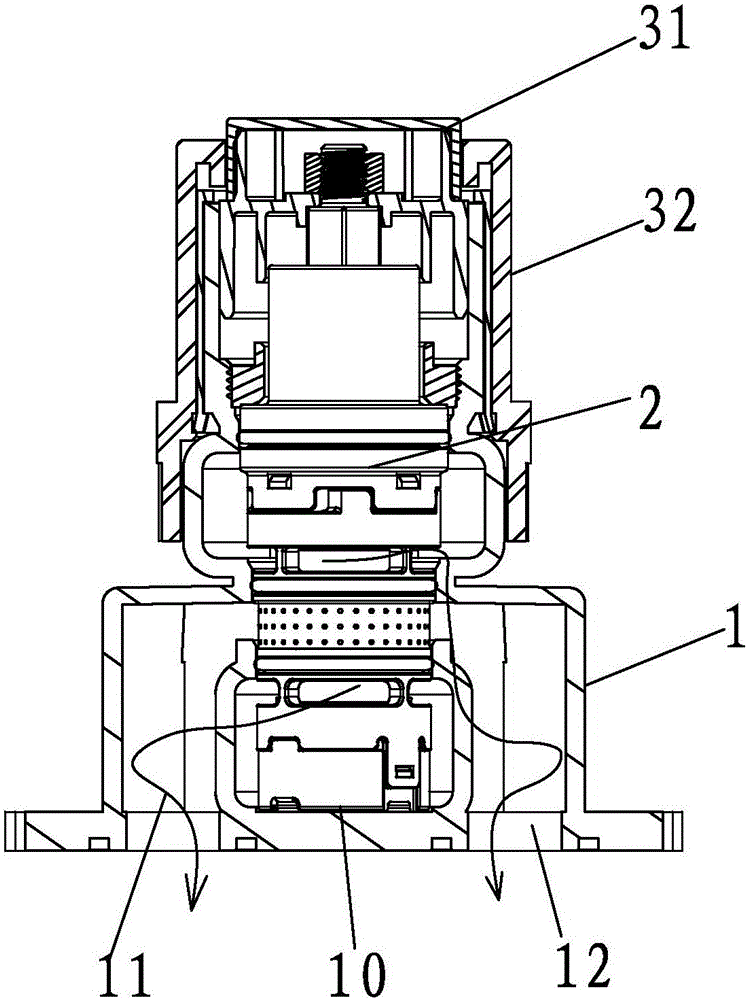

[0044] Embodiment one, such as Figure 1 to Figure 9 As shown, a multi-stage single-double control flow regulating switch valve described in this embodiment mainly includes the following parts: valve body 1, water diversion valve core 2, push button 31, adjustment sleeve 32, drive gear 51, drive rod 41 and sealing water piston 42;

[0045]When assembling, press the part 3 of the assembly, and the pressing key 31 and the adjusting sleeve 32 are integrally formed or fixedly connected in linkage, so that the adjusting sleeve 32 moves and moves together with the pressing key 31;

[0046] The flow adjustment assembly 4 is connected with the drive rod 41 and the water sealing piston 42 through a threaded connection, so that the drive rod can drive the water sealing piston 42 to move up and down along the drive rod 41; then the assembled flow adjustment assembly 4 is installed into the valve Inside the body 1, and set corresponding to each water outlet 11, 12;

[0047] Multi-stage ...

Embodiment 2

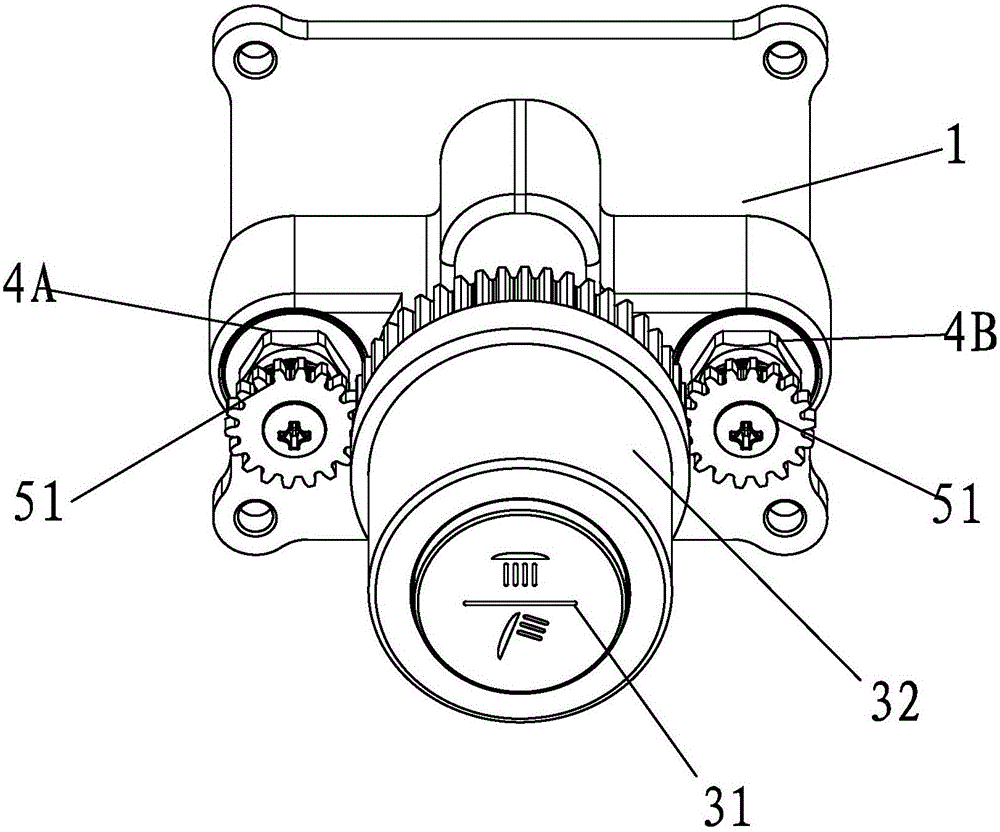

[0050] Embodiment two, such as Figure 1 to Figure 10 As shown, the multi-stage single-double control flow regulating switch valve described in the second embodiment mainly includes the following parts: valve body 1, water diversion valve core 2, push button 31, adjustment sleeve 32, driving gear 51, driving Rod 41 and water sealing piston 42; in this embodiment, the same parts as in Embodiment 1 will not be repeated, the difference is that the pressing key 31 and the adjusting sleeve 32 of the pressing component 3 are separated; the driving gear 51 is assembled. Assembled with two flow regulating components 4A, 4B;

[0051] In actual use, such as Figure 9 to Figure 11 As shown, press the pressing component 3, and press the key 31 on it to independently open the water diversion valve core 2 and form any waterway or all waterways are opened, and the adjusting sleeve 32 has already been installed by the first and second flow regulating components 4A, 4A, The driving gear 51 o...

Embodiment 3

[0054] Embodiment three, such as Figure 1 to Figure 11 As shown, the multi-stage single-double control flow regulating switch valve described in the third embodiment mainly includes the following parts: valve body 1, water diversion valve core 2, push button 31, adjustment sleeve 32, driving gear 51, driving Rod 41 and water-sealing piston 42; in this embodiment, the same parts as those in Embodiment 1 and Embodiment 2 will not be repeated. Switching position, that is, the adjustment sleeve 32 first engages with the first flow adjustment component 4A for independent adjustment, and then presses to the next switching position, that is, the linkage part 320 on the adjustment sleeve 32 and the first and second flow adjustment components 4A, 4B Engage at the same time to form a simultaneous adjustment mode; press down to make the adjustment sleeve 32 separate from the first flow adjustment assembly 4A and engage with the second flow adjustment assembly 4B, which is also an indepe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com