Concentricity measurement and adjustment restoration method for steel pipe hot extruding reamer

A repair method and technology of hole reaming machine, applied in the direction of measuring devices, instruments, metal processing, etc., can solve problems such as difficult concentricity detection, difficult repair adjustment, etc., achieve functional accuracy restoration, reduce production costs and spare parts requirements, and meet The effect of production process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

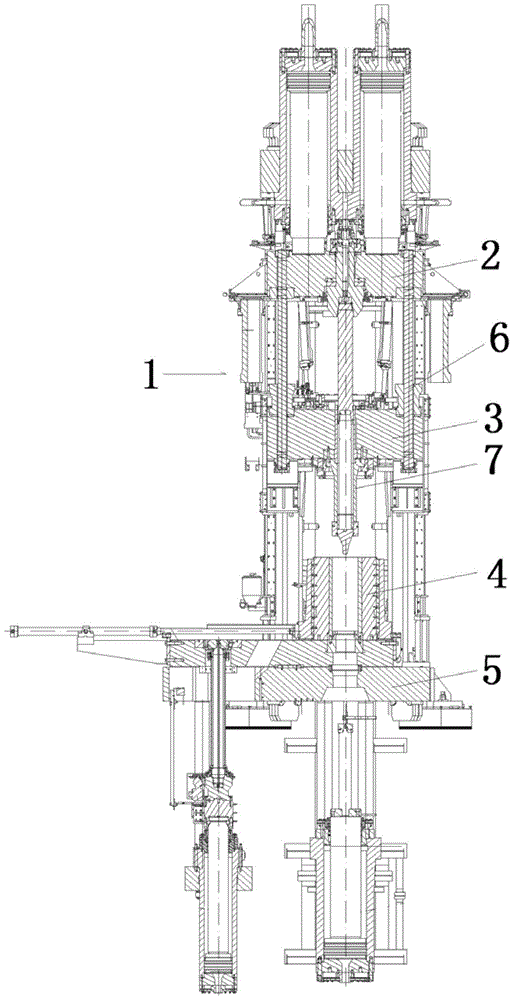

[0027] Such as figure 1 As shown, a concentricity measurement and adjustment repair method of a steel pipe hot extrusion hole reaming machine includes a hole reaming machine 1, and its specific steps are as follows:

[0028] 1) Remove the reaming rod 7 of the reaming machine 1, leaving the connecting thread at the bottom of the reaming beam 2;

[0029] 2) Take the center of the connecting thread at the bottom of the reaming beam 2 and the center of the bottom beam 5 as a reference, and connect and set the measuring steel wire;

[0030] 3) Taking the measuring steel wire as a benchmark, measure the concentricity deviation data of the upper and lower sides of the upsetting beam 3 and the upper and lower sides of the reaming cylinder 4 respectively;

[0031] 4) According to the concentricity deviation data measured in step 3), adjust the installation positions of the upsetting beam 3 and the reaming cylinder 4, adjust and repair the concentricity deviation, and meet the technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com