Method for measuring and adjusting concentricity of extrusion die applied to steel pipe hot extrusion machine

An adjustment method and extrusion die technology, which are applied in metal extrusion control equipment, metal extrusion, measuring devices, etc., can solve problems such as function and accuracy decrease, steel pipe wall thickness tolerance exceeding standard, concentricity deviation increasing, etc. Achieving the effect of restoring functional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

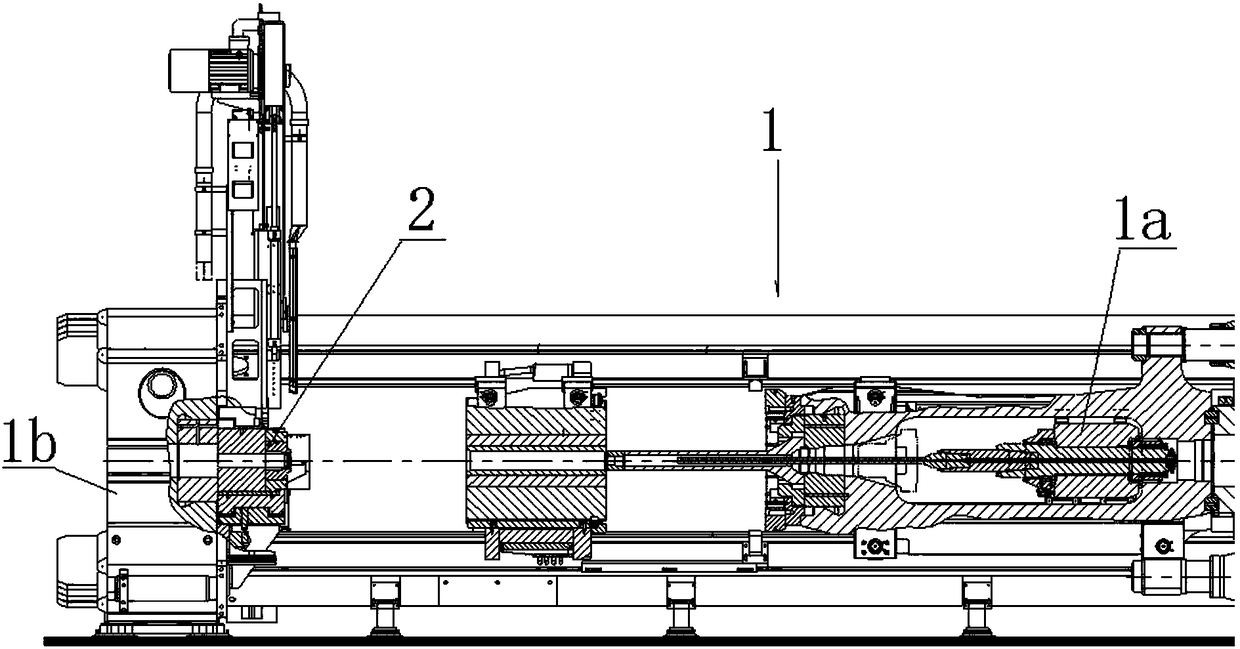

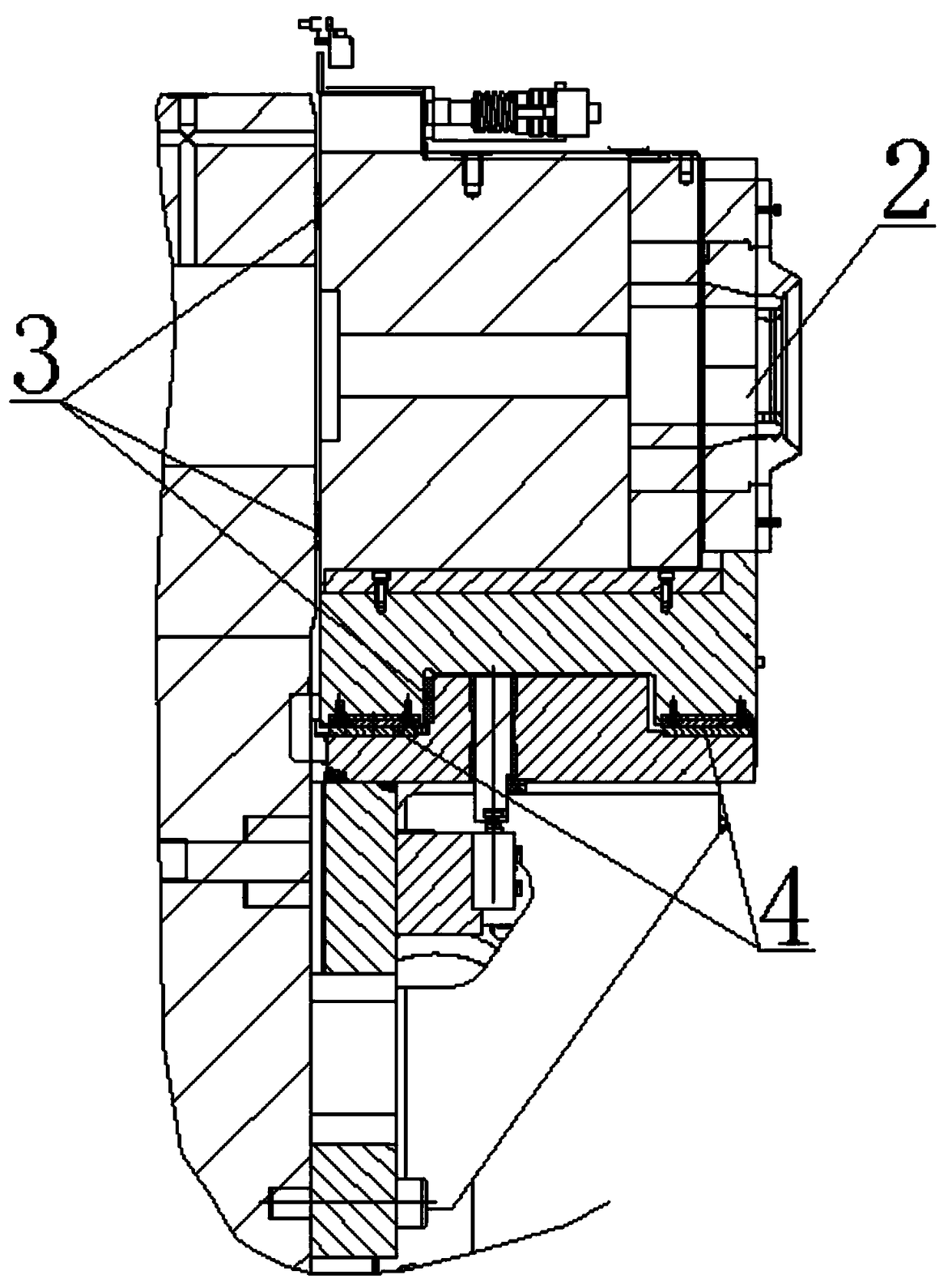

[0031] Such as figure 1 with figure 2 As shown, the method of measuring and adjusting the concentricity of the extrusion die applied to the steel pipe hot extrusion machine includes the extrusion die 2 arranged on the steel pipe hot extrusion machine assembly 1 and the vertically arranged extrusion die 2 arranged on the side of the extrusion die 3 side guide plates 3 and 2 bottom guide plates 4 arranged horizontally at the bottom of the extrusion die, the specific steps are as follows:

[0032] 1) When the extrusion die 2 is installed on the steel pipe hot extrusion machine assembly 1 for the first time, there is no concentricity deviation at this time, and the side gap between the extrusion die and the side guide plate 3 and the distance between the extrusion die and the bottom guide plate 4 are measured The bottom clearance between the two sides, the side clearance and the bottom clearance obtained from this measurement shall be taken as the reference value;

[0033] 2) W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com