Wheel-rail relation simulation fatigue test device and method

A technology for fatigue experiment and wheel-rail relationship, which is applied in the direction of measuring device, vibration test, machine/structural component test, etc. It can solve the problems of not being able to simulate the actual contact relationship between wheels and rails well, expensive test bench cost and maintenance cost, etc. High maintenance costs and other issues, to achieve the effect of low cost, long time-consuming, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

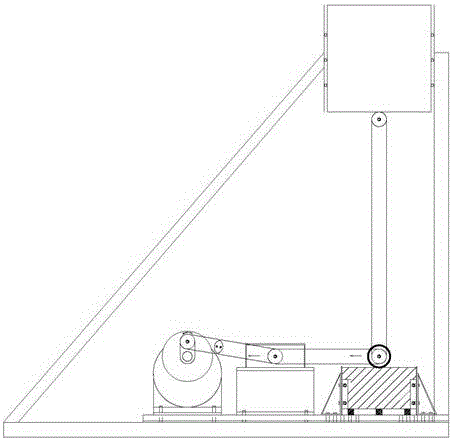

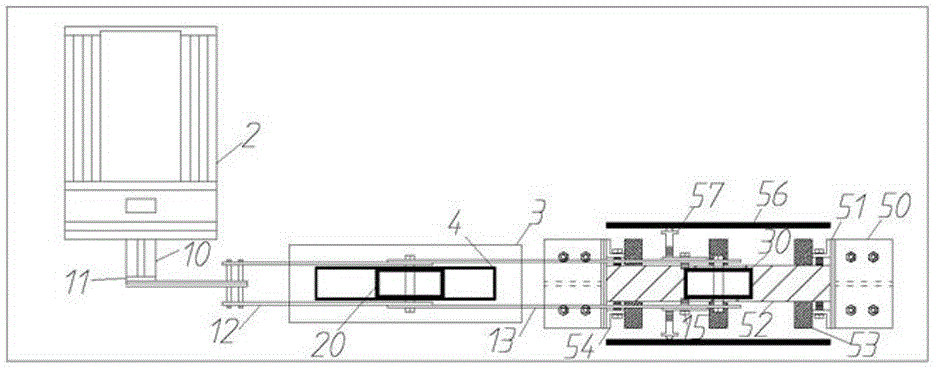

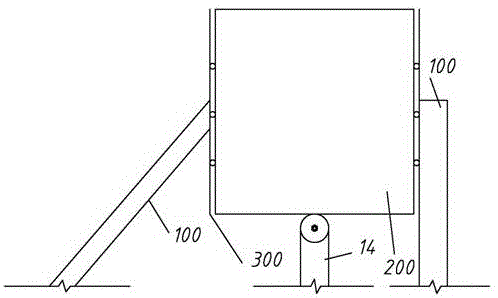

[0045] A wheel-rail relationship simulation fatigue test device, the device includes a base platform arranged on a horizontal plane, a load box is slidably connected above a loading frame fixedly installed on the base platform, a motor is installed on the base platform, and the motor is used as a driving wheel Drive the crank to rotate, the crank is connected with the transmission mechanism, and the transmission mechanism drives the simulated wheel to reciprocate horizontally on the rail specimen. The rod drives the load box to reciprocate up and down, thereby applying a dynamic load to the rail specimen placed under the simulated wheel.

[0046] According to an embodiment of the present invention, such as Figure 1-8 As shown, an indoor wheel-rail fatigue load experimental device and method are provided, specifically a new wheel-rail relationship simulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com