Pressure-sensitive sensor, touch feedback device and related device

A tactile feedback and sensor technology, applied in the field of tactile feedback devices and related devices, and pressure-sensitive sensors, can solve the problems of complex structure of pressure-sensitive sensors, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

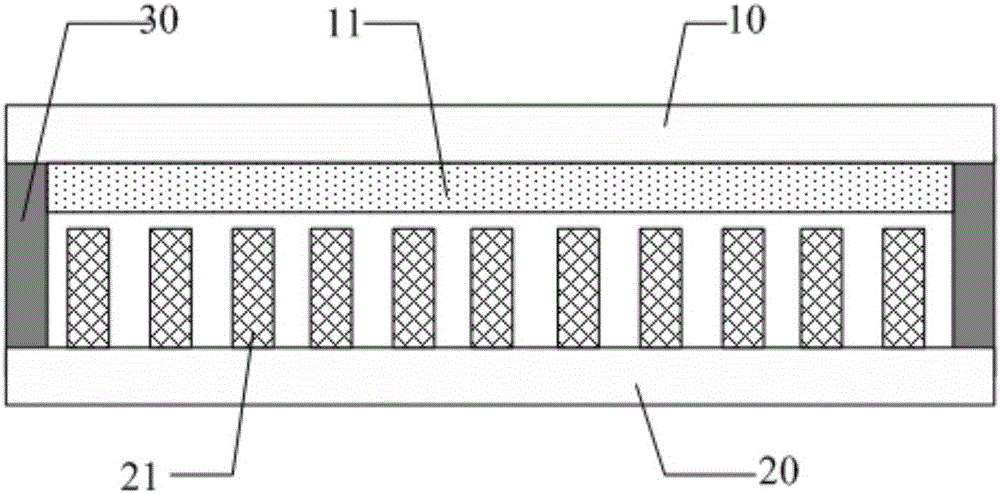

[0054] In the above-mentioned pressure-sensitive sensor provided by the embodiment of the present invention, such asfigure 1 As shown, the pressure sensing electrode 21 is a columnar structure. In this way, when the first substrate 10 and / or the second substrate 20 are subjected to pressure, the pressure-sensitive detection electrode 21 can be brought into contact with the common electrode.

Embodiment 2

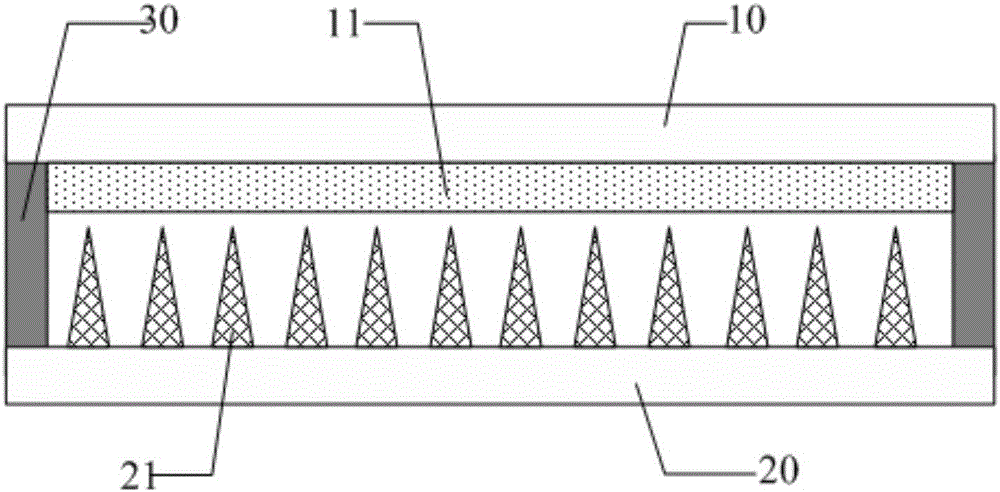

[0056] Preferably, in the above-mentioned pressure-sensitive sensor provided by the embodiment of the present invention, such as Figure 2a and Figure 2b As shown, the area of the cross section of the pressure sensing electrode 21 parallel to the second substrate 20 decreases as the distance between the cross section and the second substrate 20 increases. That is, it is equivalent to setting the pressure-sensitive detection electrodes in a structure of "thin at the top and thick at the bottom", "up" refers to a direction away from the second substrate, and "down" refers to a direction close to the second substrate. In this way, "bottom thick" can increase the contact area between the pressure-sensitive detection electrodes and the second substrate, thereby increasing the adhesion force, and "upper thin" can not only reduce weight, but also increase the distance between adjacent pressure-sensitive detection electrodes, thereby Avoid interfering with each other.

[0057] Pr...

Embodiment 3

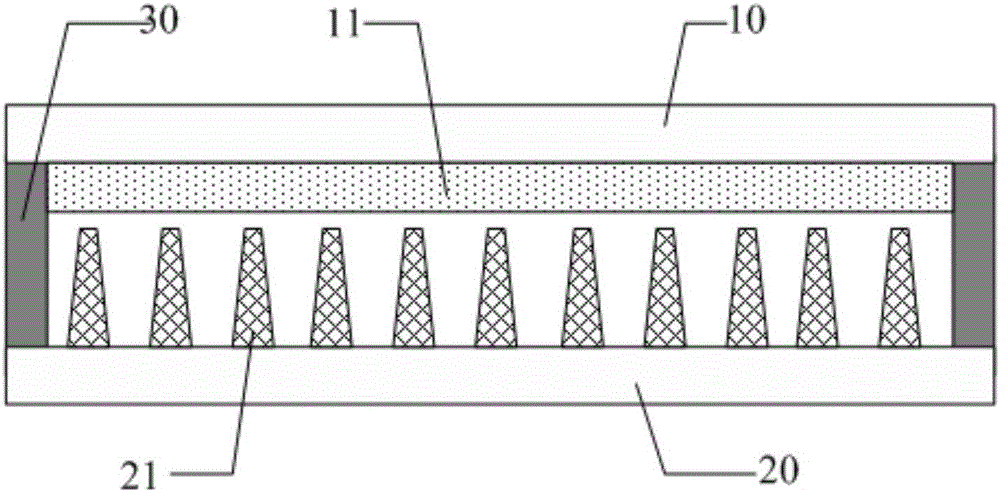

[0062] In the above-mentioned pressure-sensitive sensor provided by the embodiment of the present invention, such as Figure 3a and Figure 3b As shown, the pressure sensing electrode 21 includes a first electrode part 211 located on the side of the second substrate 20 facing the first substrate 10, and a second electrode part 212 located on the side of the first electrode part 211 facing the first substrate 10; wherein ,

[0063] The orthographic projection of the first electrode part 211 on the second substrate 20 covers the orthographic projection of the second electrode part 212 on the second substrate 20;

[0064] The area of the cross section of the second electrode portion 212 parallel to the second substrate 20 decreases as the distance between the cross section and the second substrate 20 increases.

[0065] Preferably, in the above-mentioned pressure-sensitive sensor provided by the embodiment of the present invention, such as Figure 3a As shown, the second ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com