A kind of manufacturing method of piano sound source component

A manufacturing method and sound source technology, which are applied to stringed instruments, wood compression, instruments, etc., can solve the problems of poor positional accuracy of bridges and ribs, affecting the acoustic quality of pianos, and being unsuitable for mass production, and achieve improved stability and excellent acoustics. quality, the effect of improving production quality and acoustic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

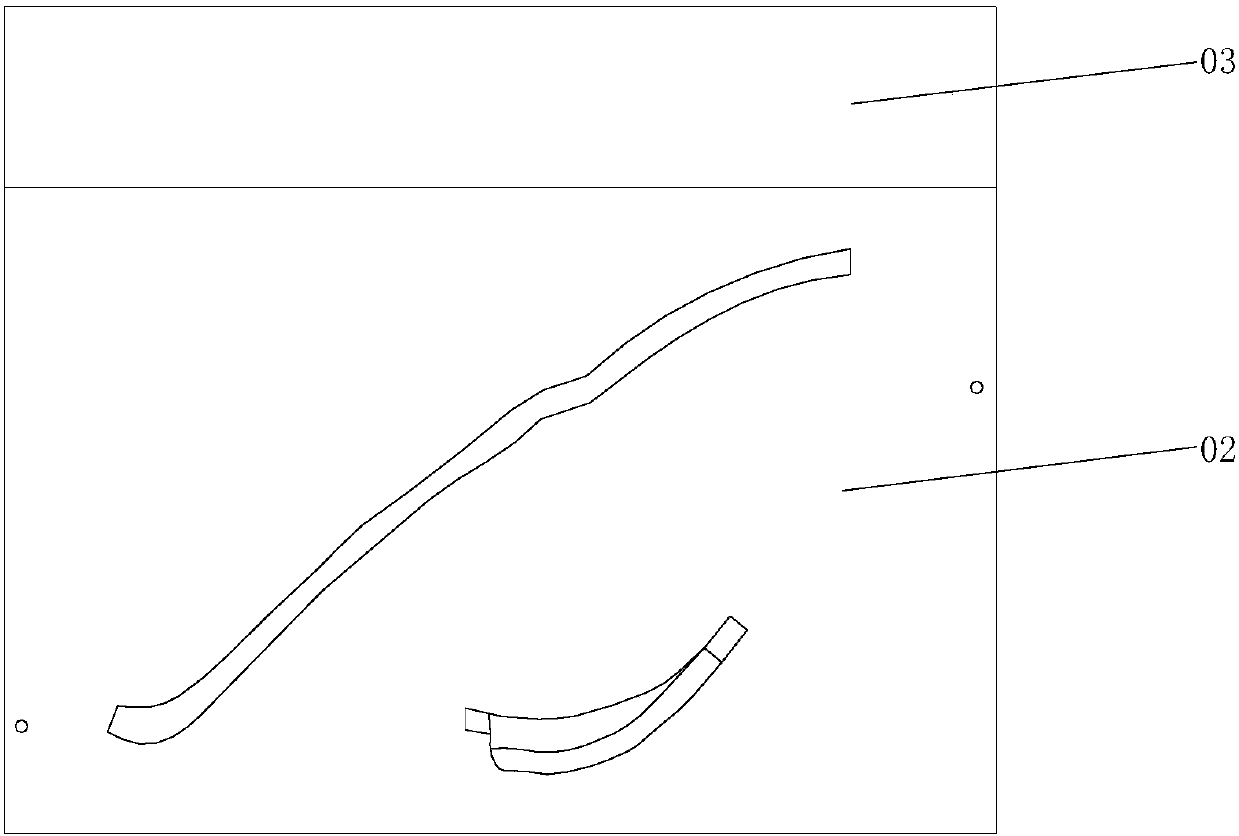

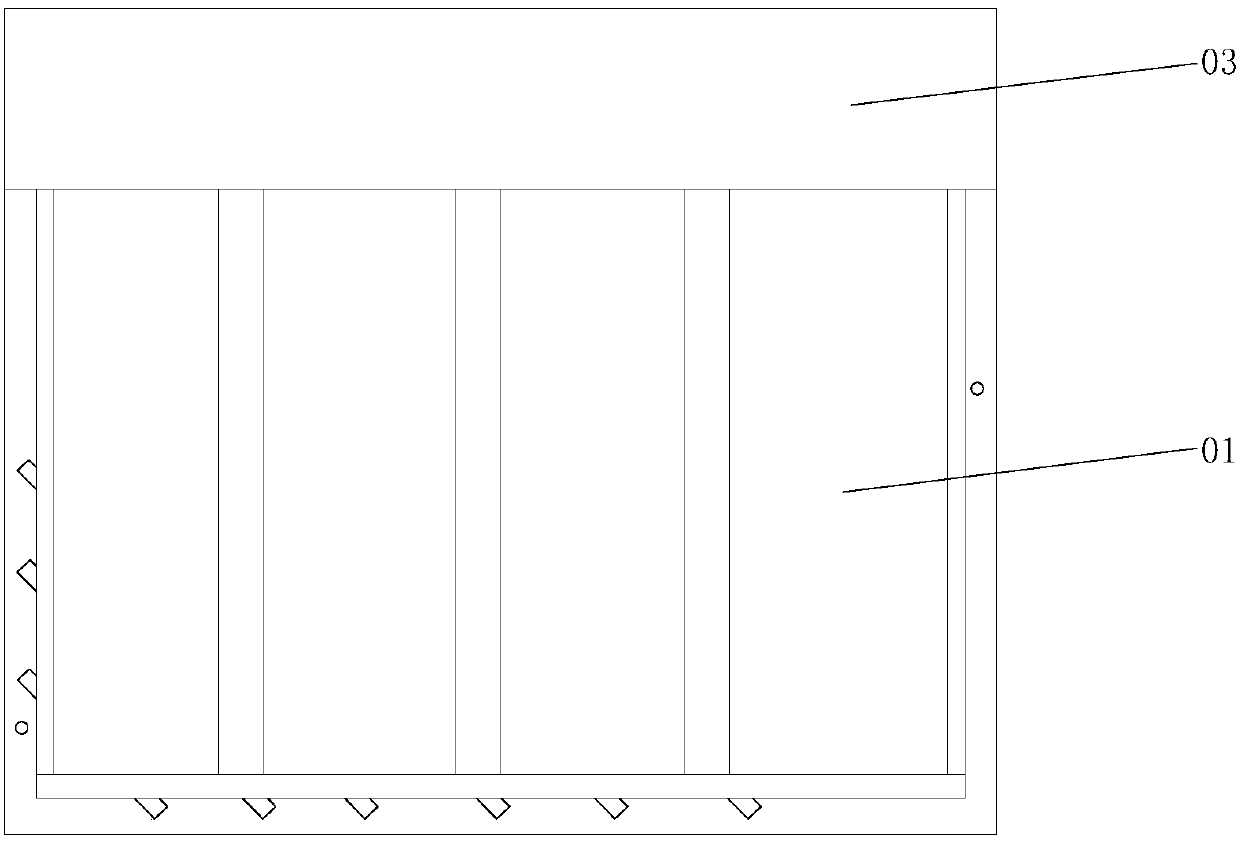

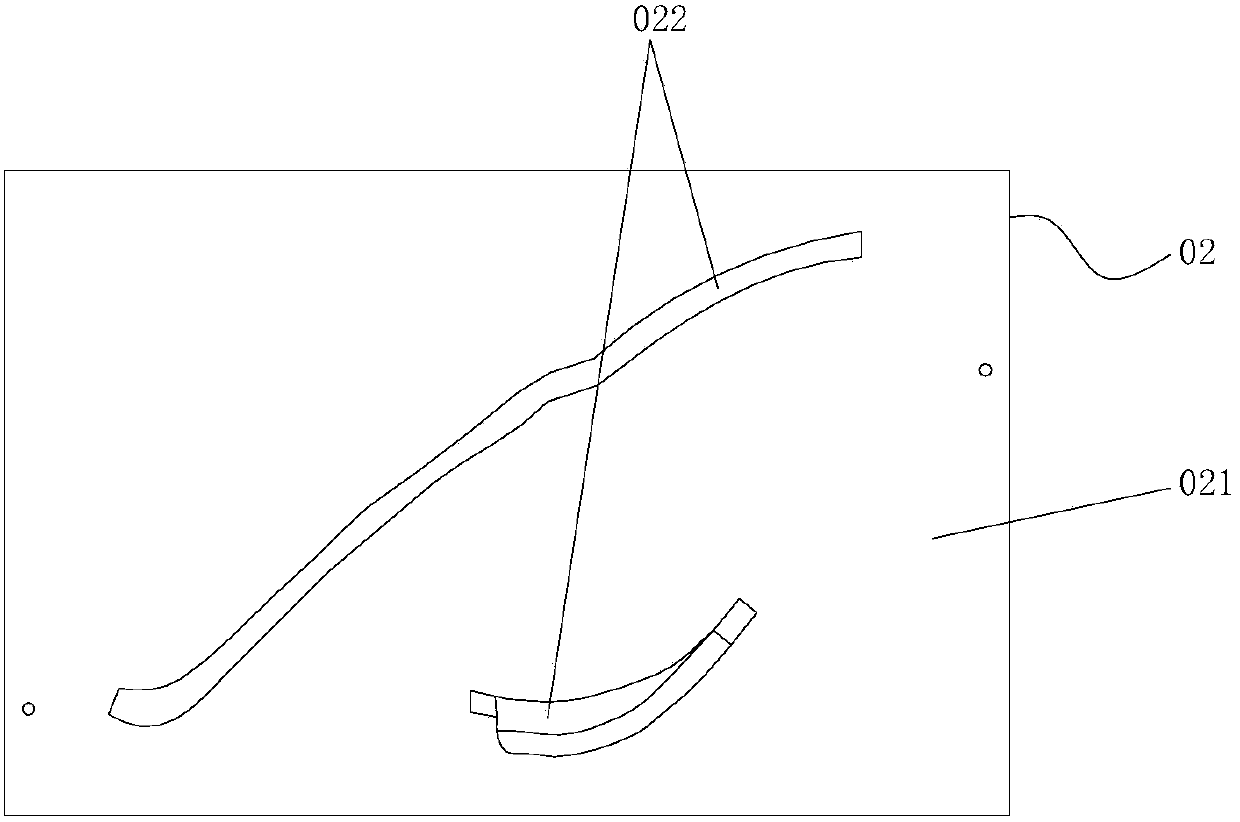

[0031] Such as Figure 5 to Figure 8 Shown in one of them, a kind of manufacturing method of piano sound source component of the present invention, this manufacturing method comprises the following steps:

[0032] 1) Production of the soundboard: the soundboard is processed and formed on the soundboard cold-pressing and shaping machine 1. The soundboard cold-pressing and shaping machine 1 has a lower mold 11 and an upper mold 12. The upper mold 12 is driven by the lifting driver 13 on the lower mold 11. Do the lifting movement directly above, the upper end surface of the lower mold 11 is provided with a slot 111 for placing the bridge 2, and the lower end surface of the upper mold 12 is provided with a plurality of pressing plates 14 matching the shape of the ribs 3 at intervals, and the sound board The specific process of making is as follows,

[0033] 1-1. Put the bridge 2 in the slot 111 of the lower mold 11, wherein the upper end of the bridge 2 extends out of the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com