Inductive coupling plasma reactor

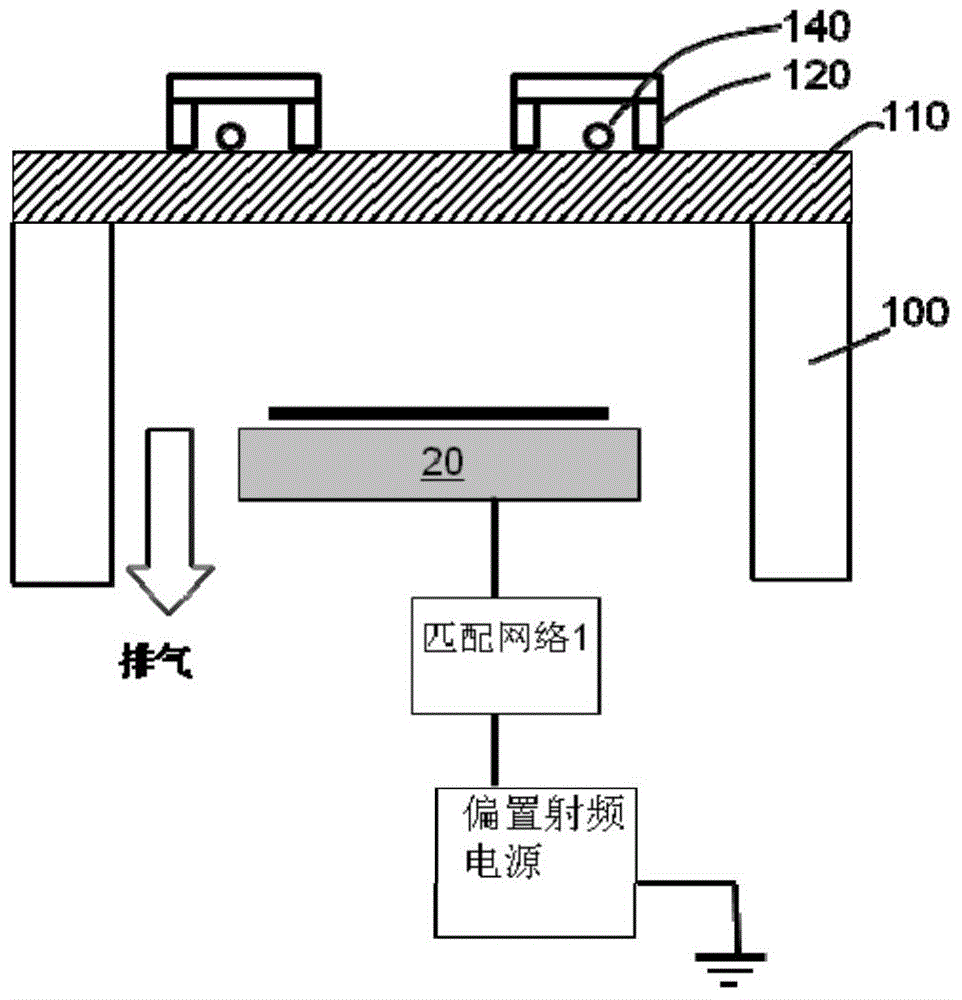

A plasma reactor, inductive coupling technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as uneven plasma concentration distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

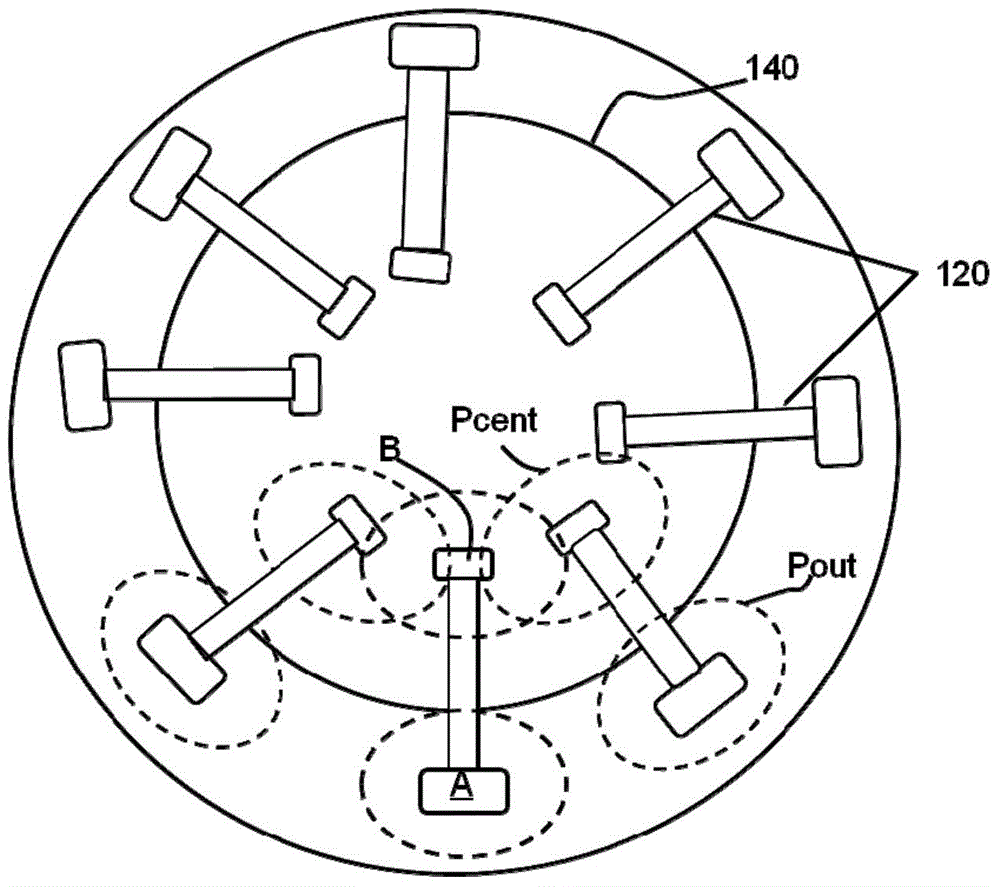

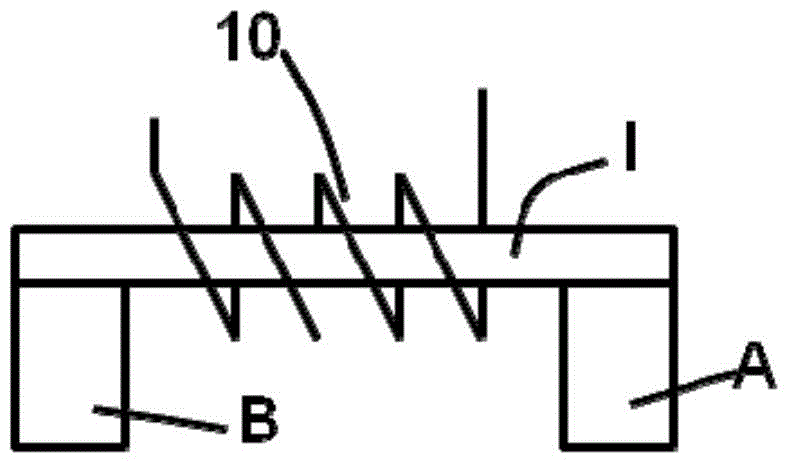

[0017] The present invention aims to solve the problem of uneven distribution of plasma concentration in the central area and the peripheral area in the inductively coupled plasma processing device, and proposes such as figure 2 The iron core and coil structure of the first embodiment of the present invention is shown, wherein the iron core includes a horizontally extending portion I, and also includes a first downwardly extending portion A, a second downwardly extending portion B1 and a third downwardly extending portion B2, An induction coil is wound on the horizontal extension I11 between the first and second downward extensions.

[0018] The magnetic field line circuit such as figure 2 As shown by the dotted line in the middle, the first loop passes along A, I11, B1 and finally returns to A through the air, and the second loop passes through A, I11, I12, B2 and finally returns to A through the air between the lower end of B2 and A.

[0019] Wherein, end A is located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com