Manufacturing method of metal wafer-level buried-hole type surface acoustic filter chip packaging structure

A filter chip and packaging structure technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of long process, large structure size, high cost, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

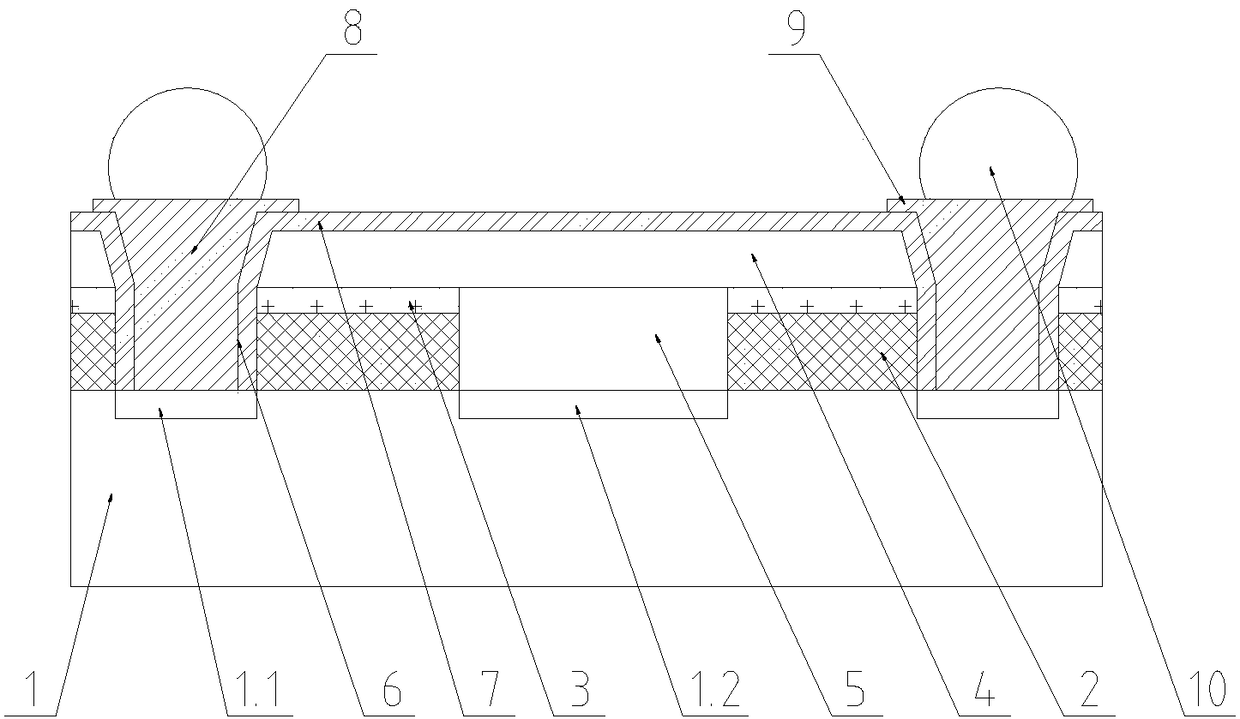

[0062] A method for manufacturing a package structure of a metal wafer-level buried-hole type surface acoustic filter chip, comprising the following process steps:

[0063] Step 1, see figure 2 , take a surface acoustic filter chip wafer;

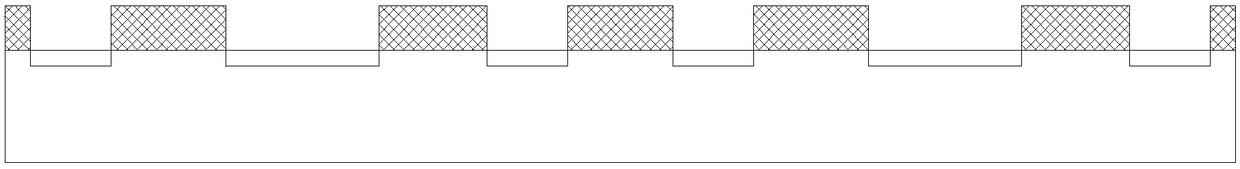

[0064] Step 2. Prepare the first insulating layer

[0065] see image 3 1. Apply a certain thickness of insulating glue on the surface acoustic filter chip wafer by glue coating process, such as PI (polyimide), PA (nylon, polyamide), and use photolithography and development to seal the electrode area and Removal of the insulating glue at the sensing area of the chip;

[0066] Step 3: Bonding wafer openings and bonding

[0067] see Figure 4 , take a piece of bonded wafer, first make a hole on the bonded wafer corresponding to the position above the electrode of the surface acoustic filter chip wafer, and then pass the bonding glue and surface acoustic filter through the bonded wafer that has been holed. Chip wafers are bonded toget...

Embodiment 2

[0082] A method for manufacturing a package structure of a metal wafer-level buried-hole type surface acoustic filter chip, comprising the following process steps:

[0083] Step 1, see Figure 10 , take a surface acoustic filter chip wafer;

[0084] Step 2. Prepare the first insulating layer

[0085] see Figure 11 1. Apply a certain thickness of insulating glue on the surface acoustic filter chip wafer by glue coating process, such as PI (polyimide), PA (nylon, polyamide), and use photolithography and development to seal the electrode area and Removal of the insulating glue at the sensing area of the chip;

[0086] Step 3: Half-etch and bond the wafers and bond them

[0087] see Figure 12 , take a bonded wafer, first half-etch and open the bonded wafer corresponding to the position above the electrode of the surface acoustic filter chip wafer, and then connect the bonded wafer that has been half-etched to the surface through the adhesive The acoustic filter chip wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com