Sound-absorbent element for an air outlet

A technology for exhaust devices and components, which is applied in the direction of airflow control components, applications, and sound-generating devices, which can solve the problems of small installation space for filter devices, and achieve improved noise reduction or suppression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

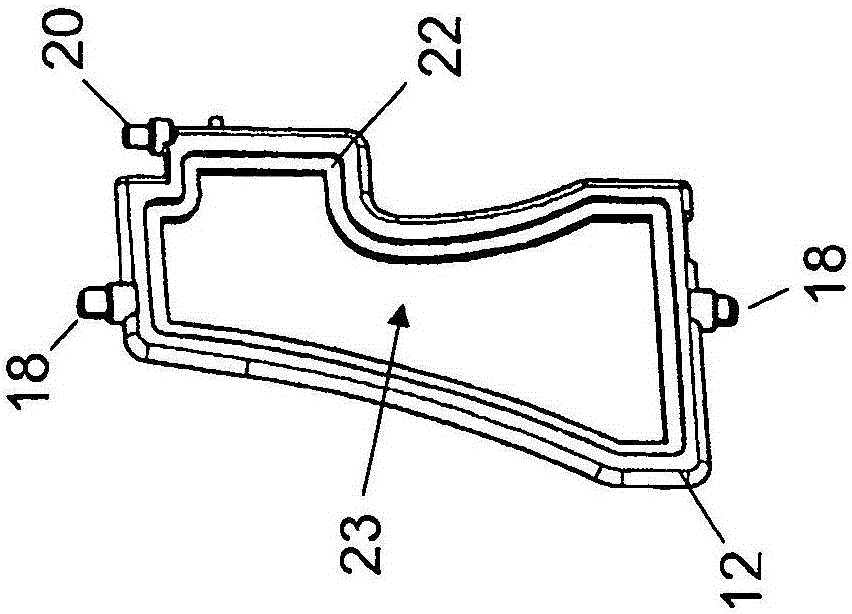

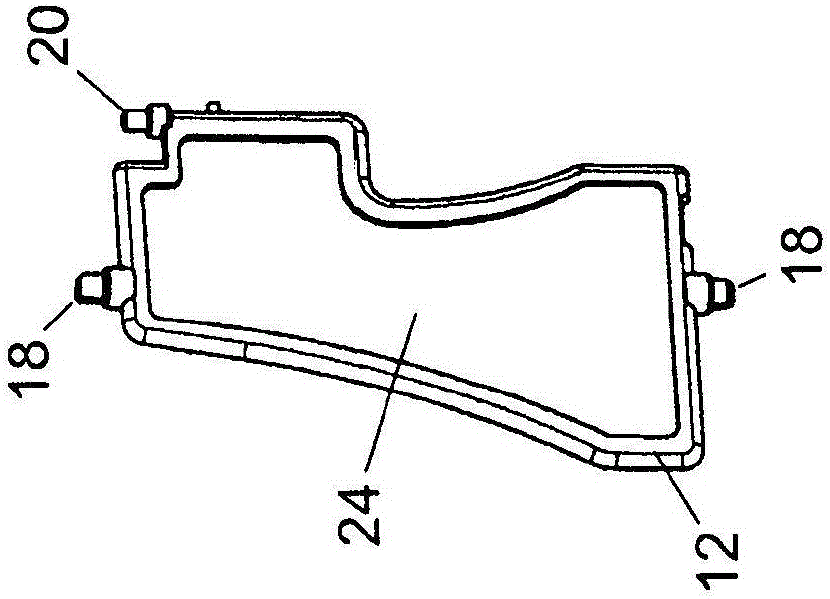

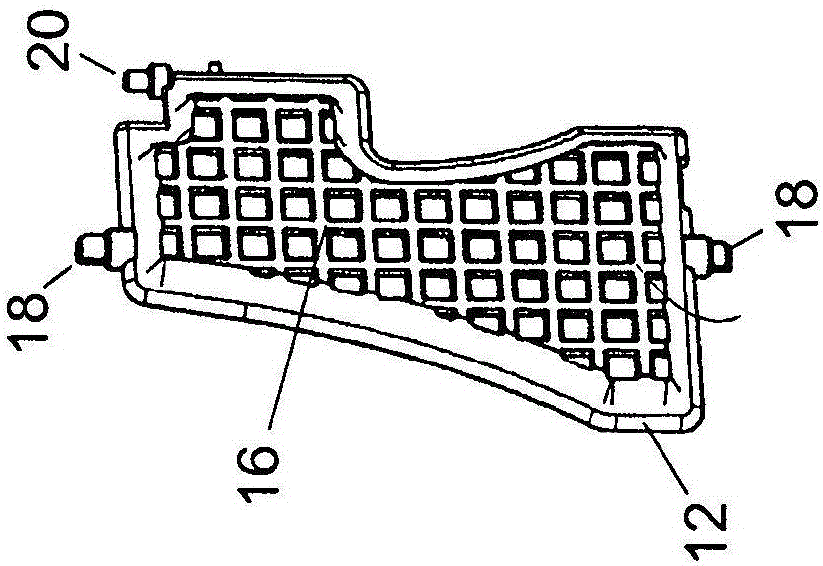

[0051] figure 1 A schematic view of the carrier 12 for the sound-absorbing element in the first embodiment is shown. The bracket 12 is configured as an exhaust device 30 (not in figure 1 Components of a vertical blade shown in ). The support 12 has two bearing pins 18 , via which the vertical blades or the support 12 are rotatably mounted in the housing 31 of the exhaust device 30 . Furthermore, the support 12 has pins 20 , wherein a plurality of vertical blades or support 12 are pivoted via their pins 20 and via coupling rods which connect the individual pins 20 to one another. The support 12 configured as a frame has a step 22 on the inside, onto which a coating 14 is applied with a sound-absorbing material. The frame 12 preferably has a step 22 of this type on both sides, so that a coating of sound-absorbing material can be applied to the support 12 on both sides and can be connected to the support 12 . The region 23 enclosed by the step 22 and the frame-shaped carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com