Boring machine boring bar support boring bar centering device

A boring bar support and centering device technology, applied in the direction of tool holders, etc., can solve the problems of easy to squeeze the boring bar, damage the machine tool, inconvenience, etc., achieve reasonable clearance, reduce radial pressure, and avoid the effect of squeezing the boring bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

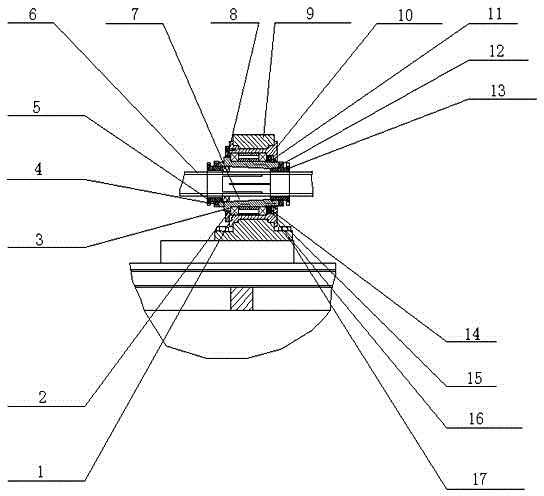

[0011] refer to figure 1 , the boring bar centering device of the boring machine boring bar support boring bar of the present embodiment, it comprises taper bearing 1, taper bearing left end cover 2, taper bearing inner fixing sleeve 3, left back tightening nut 4, left adjusting threaded sleeve 5, nylon taper sleeve 7. The upper half gland of the boring bar bracket 9, the right end cover of the taper bearing 10, the positioning square key 11, the right back tightening nut 12, the right adjusting thread sleeve 13, the keyway nut 14, the set screw 15, the outer fixing sleeve of the taper bearing 16 and The fixed base 17 of the boring bar bracket, the outer fixing sleeve 16 of the cone bearing and the fixing base 17 of the boring bar bracket, and the upper half gland 9 of the boring bar bracket are fixedly connected, and the cone bearing 1 and the outer fixing sleeve 16 of the cone bearing are matched and fixed outside the cone bearing Inside the sleeve 16, the left end cover 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com