Hole punching machine and hole punching method

A punching machine and machine head technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of drill bit temperature rise, waste of manpower and time, limitations, etc., to achieve The effect of high degree of automation, accurate and fine control, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below by embodiment and with reference to accompanying drawing, the present invention will be further described.

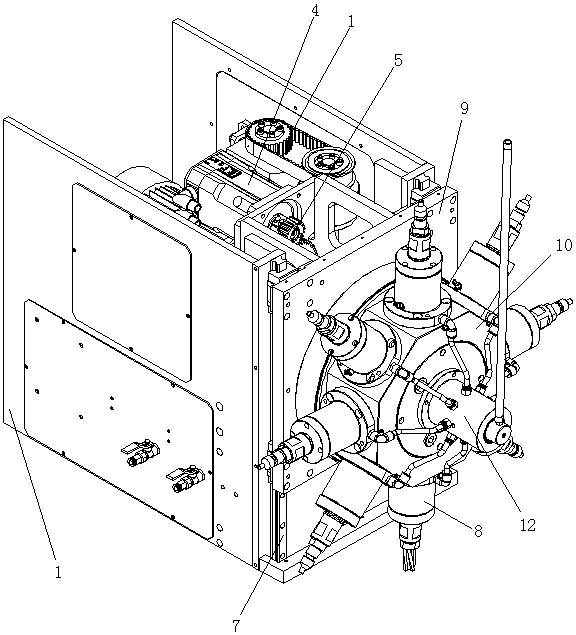

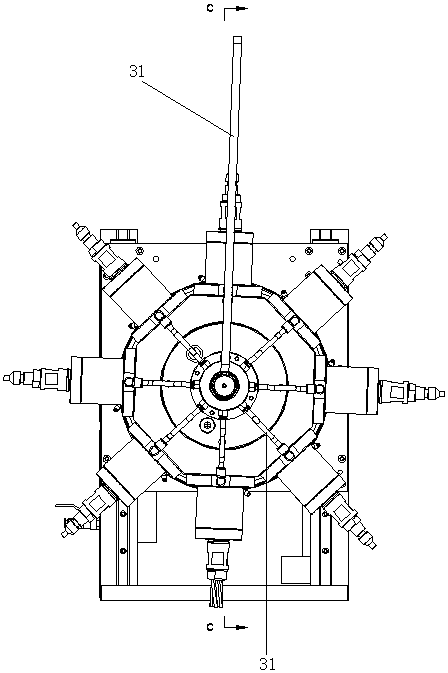

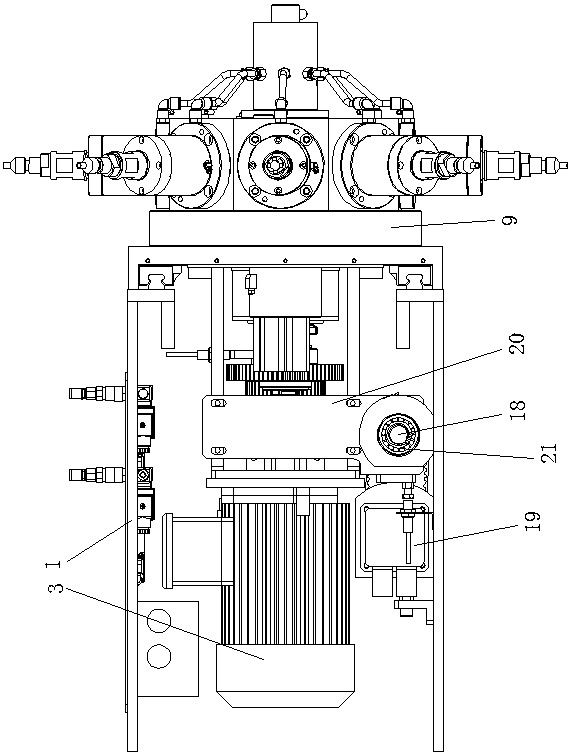

[0032] see Figure 1 to Figure 6 , the punching machine of the present invention includes a frame 1, a main shaft 2, a main drive motor 3, a central controller, a tool selection device, a head lifting device, a tool drive module 8 (head), a head mounting plate 9, Tool drive module mounting seat 10, tool cooling device 12, driving gear 13. The cutter driving module 8 is installed on the cutter driving module mounting seat 10, and the cutter driving module mounting seat 10 is installed on the machine head mounting plate 9 and can perform circular rotation. The head mounting plate 9 is installed on the guide rail 7, and the guide rail 7 is installed on the frame 1. The head lifting device is connected with the head mounting plate 9 to realize the overall movement of the head up and down. The main drive motor 3 and the driving gear 13 are respectively instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com