Multi-angle drilling device

A drilling device, multi-angle technology, applied in drilling/drilling equipment, portable drilling rigs, workbenches, etc., can solve the problems of low processing efficiency, angle limitation, high cost, save production cost, improve work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

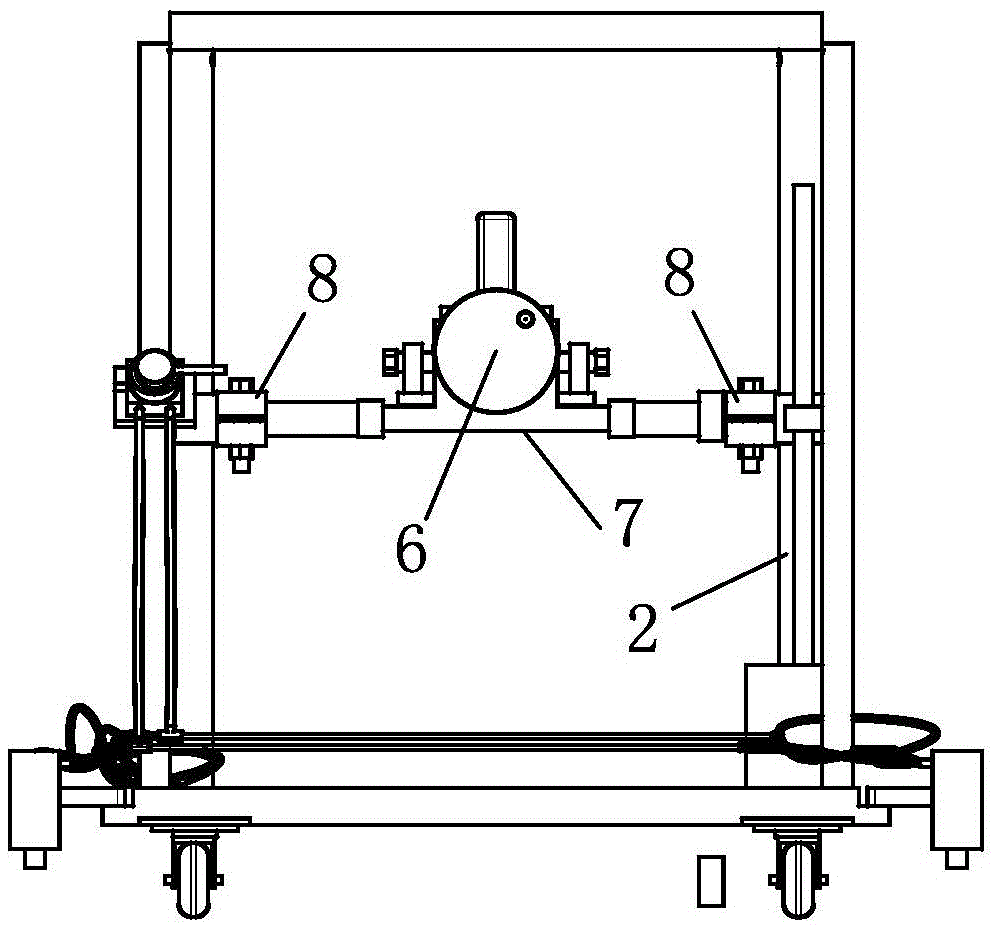

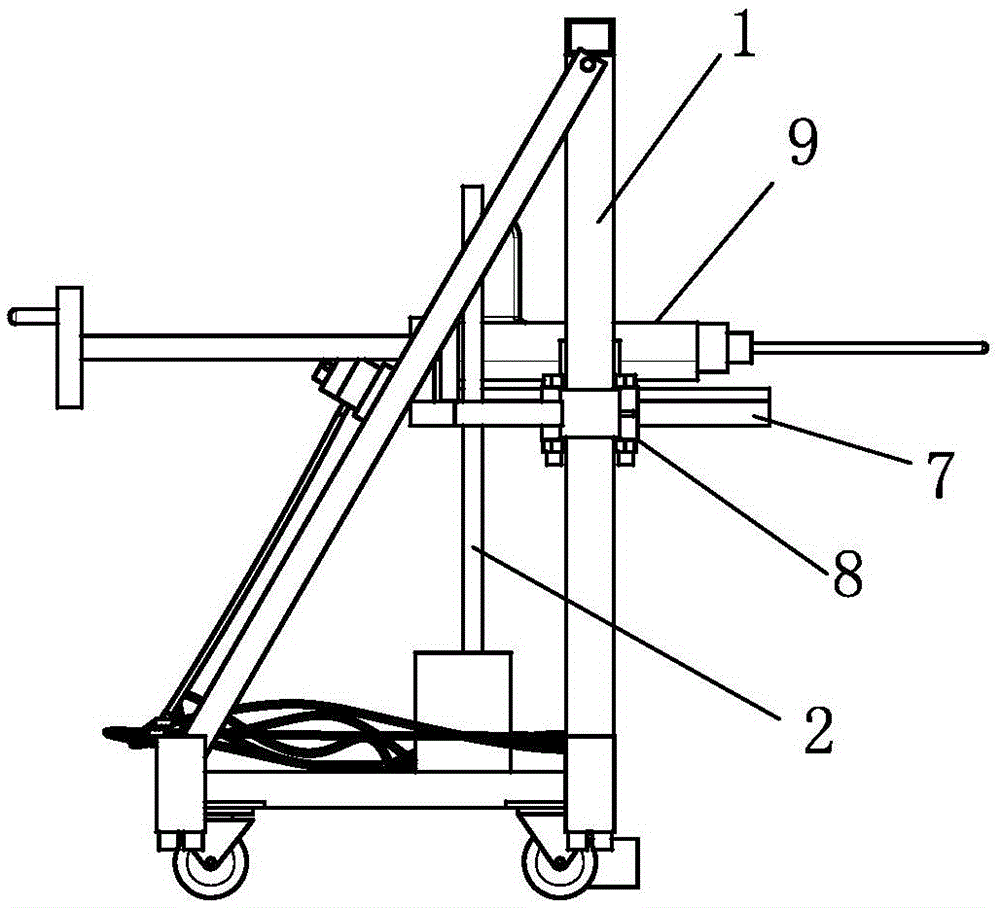

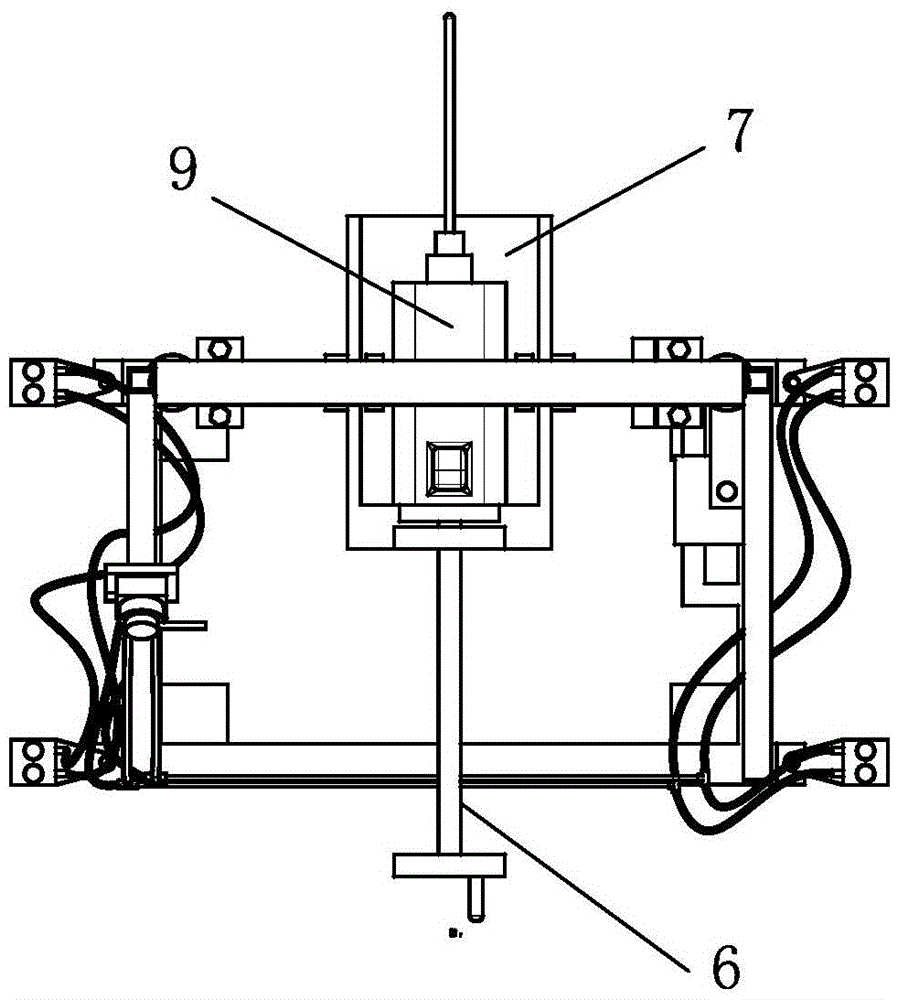

[0019] Embodiment: a kind of multi-angle drilling device of the present invention, as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 As shown, it includes a fixed frame 1 with a base, the fixed frame 1 is provided with a slide rail and an electric drill fixed table 7 that moves up and down along the slide rail; the electric drill fixed table 7 is provided with a tray for fixing the electric drill 9, and the drive tray is on The feeding device 6 that moves back and forth on the electric drill fixed table 7.

[0020] The electric drill fixed table 7 is placed horizontally, and the left and right ends are shaft structures, and the shafts at both ends are coaxially arranged and connected on the slide seat of the slide rail through bearings. The bearing connection structure enables the electric drill fixing table 7 and the electric drill on it to rotate as a whole, so that the angle of the drill bit can be adjusted according to the angle requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com