Tubular part welding rapid butt-joint positioning device

A technology for positioning devices and tubular parts, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of unguaranteed welding accuracy and pipeline coaxiality, unfavorable on-site operation, construction space constraints, etc., to achieve shortening The effect of workload, easy to master, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

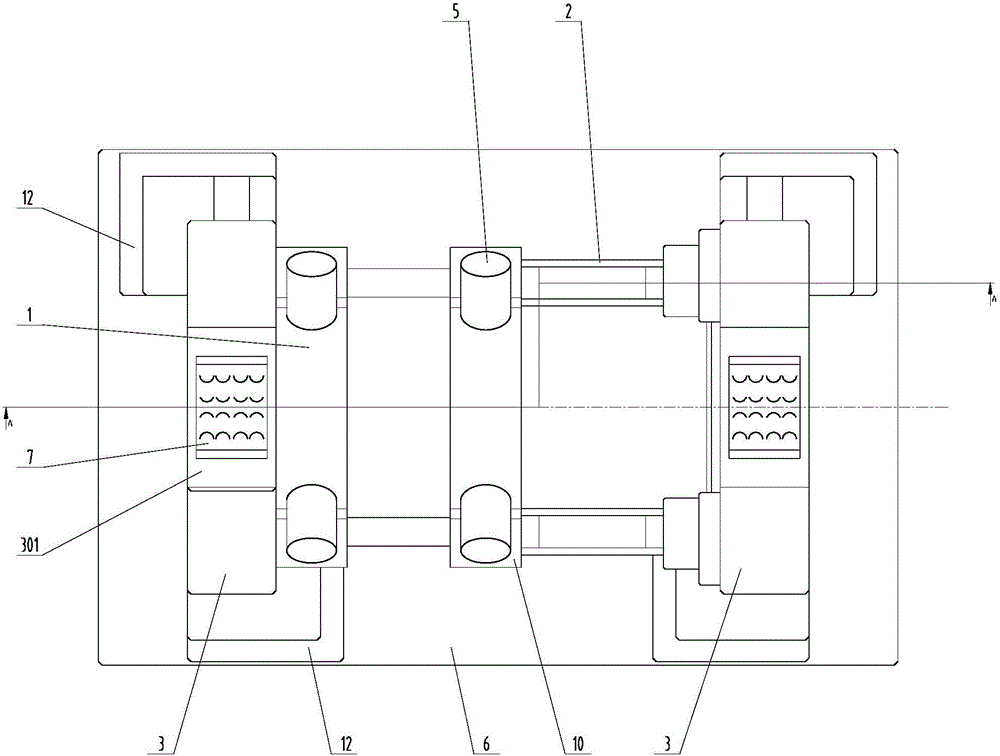

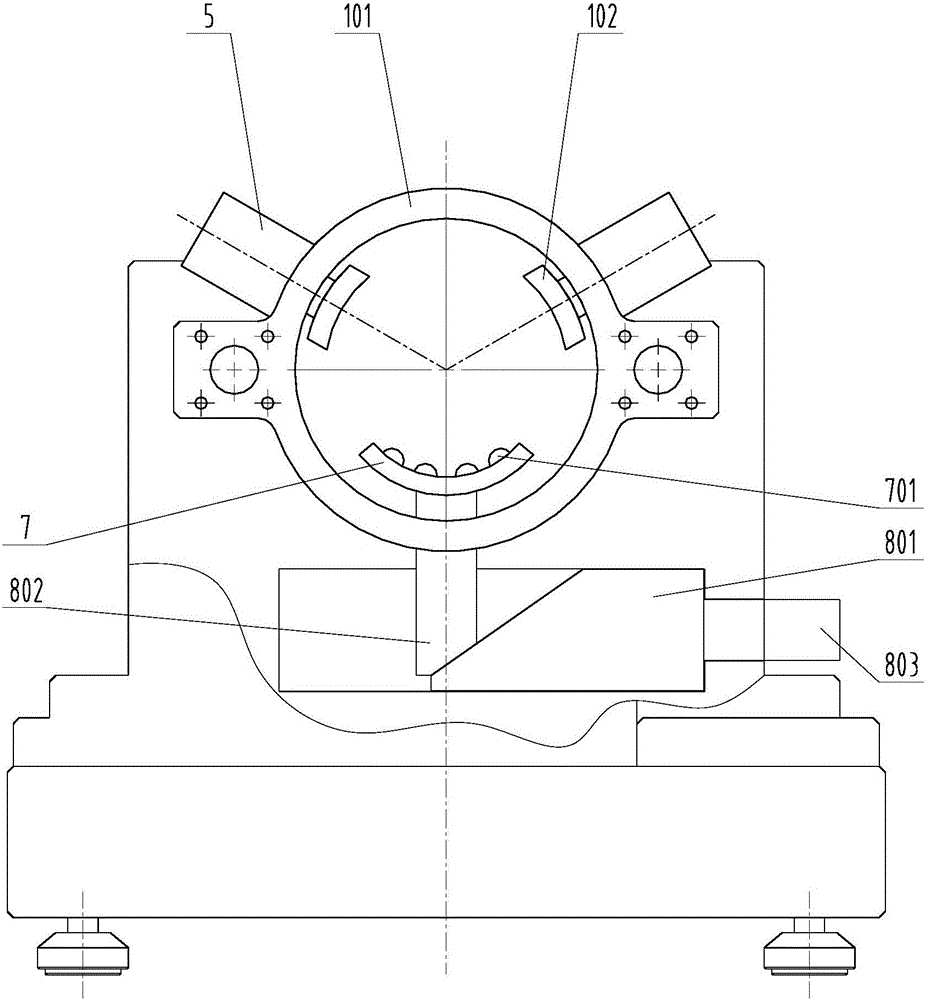

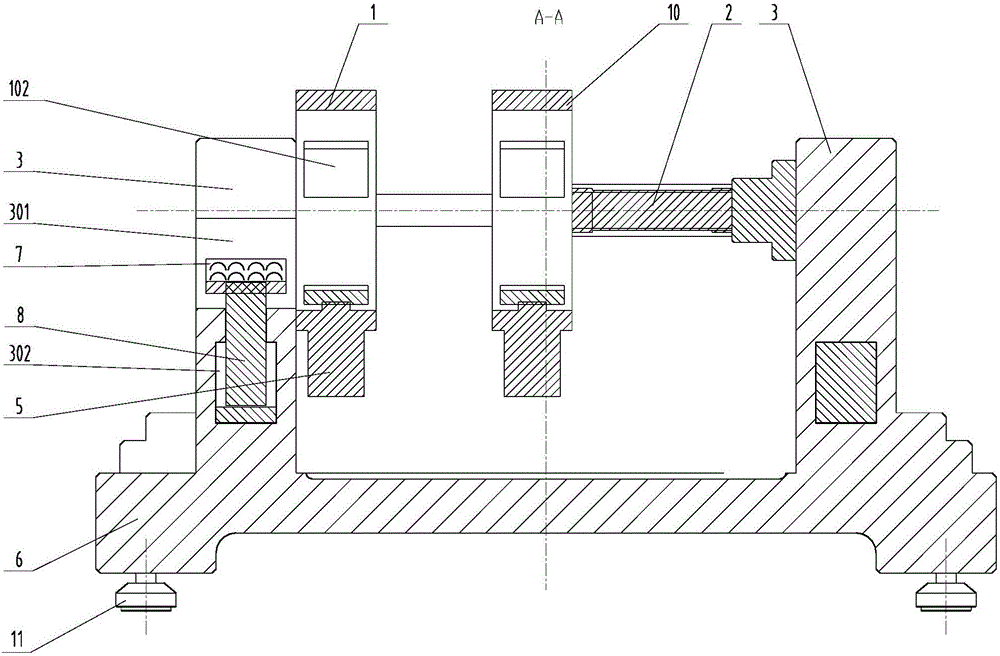

[0032] Such as Figure 1~4 As shown, on the horizontal support base 6, a pair of "U"-shaped support frames 3 with an upward opening are vertically spaced and parallelly fixed by two pairs of right-angled bending support angles 12, and the bottom of the support base 6 is provided with shock-absorbing support feet 11. The right-angle outer sides of the bottom of the support frame 3 are respectively close to the right-angle inner sides of the right-angle bending support angle 12, and the right-angle bending support angle 12 is fixed on the support base 6 by a plurality of bolts arranged at intervals, which plays a greater role in the support frame 3. Good stopper action.

[0033] The fixed clamping assembly 1 and the movable clamping assembly 10 are coaxially arranged on the inner side of the support frame 3. The fixed clamping assembly 1 is fixedly installed on one support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com