Drilling machine controlling lifting of workbench through hydraulic oil

A technology of workbench and hydraulic oil, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high cost, time-consuming and laborious, etc., and achieve the effects of small inertia, noise reduction and stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

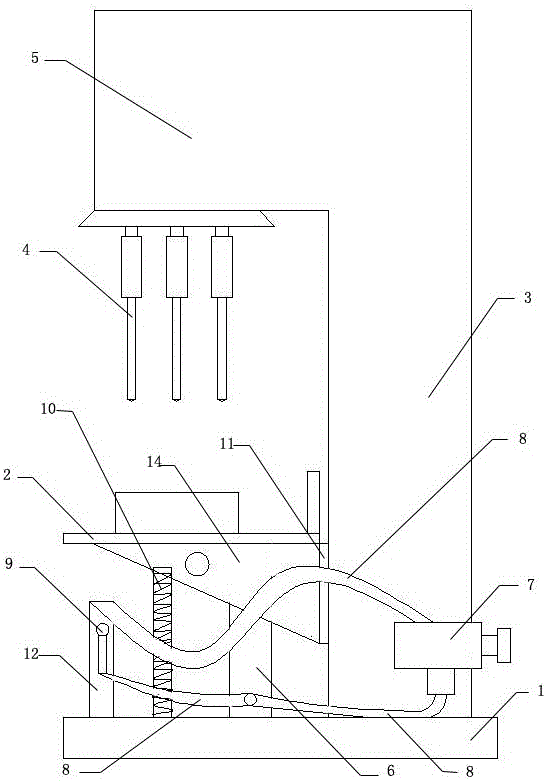

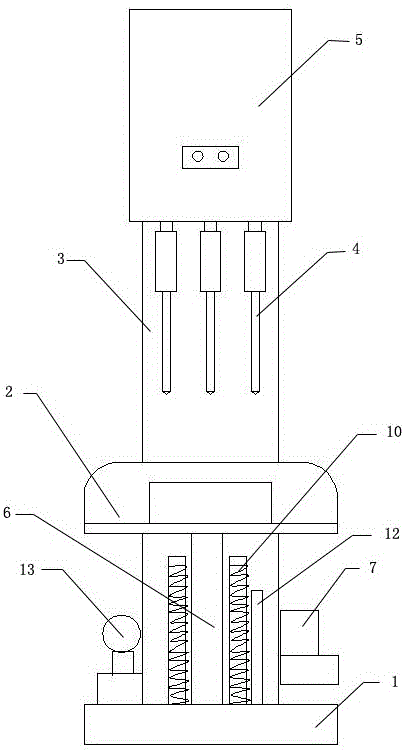

[0018] A drilling machine that uses hydraulic oil to control the lifting of a workbench. It includes a base 1, a workbench 2, a column 3, a drill bit 4, a main shaft gearbox 5, and a hydraulic control device. The hydraulic control device includes a lifting oil pump 6, which is sequentially connected through an oil pipe 8 Oil valve 9, hydraulic oil pump 7, lifting oil pump 6; lifting oil pump 6 is installed on base 1, workbench 2 is placed on lifting oil pump 6, workbench 2 can move up and down with lifting oil pump 6, hydraulic control device also includes motor 13, The motor 13 is connected to the hydraulic oil pump 7 through a belt to provide power for the flow of hydraulic oil.

Embodiment 2

[0020] A drilling machine that uses hydraulic oil to control the lifting of a workbench. It includes a base 1, a workbench 2, a column 3, a drill bit 4, a main shaft gearbox 5, and a hydraulic control device. The hydraulic control device includes a lifting oil pump 6, which is sequentially connected through an oil pipe 8 Oil valve 9, hydraulic oil pump 7, lifting oil pump 6; lifting oil pump 6 is installed on base 1, workbench 2 is placed on lifting oil pump 6, workbench 2 can move up and down with lifting oil pump 6, hydraulic control device also includes motor 13, The motor 13 is connected to the hydraulic oil pump 7 through a belt to provide power for the flow of hydraulic oil.

[0021] The motor 13 is installed on one side of the column 3, and the hydraulic oil pump 7 is installed on the other side of the column 3, corresponding to the motor 13. The pulley of the motor 13 is connected to the pulley of the hydraulic oil pump 7 through a belt.

Embodiment 3

[0023] A drilling machine that uses hydraulic oil to control the lifting of a workbench. It includes a base 1, a workbench 2, a column 3, a drill bit 4, a main shaft gearbox 5, and a hydraulic control device. The hydraulic control device includes a lifting oil pump 6, which is sequentially connected through an oil pipe 8 Oil valve 9, hydraulic oil pump 7, lifting oil pump 6; lifting oil pump 6 is installed on base 1, workbench 2 is placed on lifting oil pump 6, workbench 2 can move up and down with lifting oil pump 6, hydraulic control device also includes motor 13, The motor 13 is connected to the hydraulic oil pump 7 through a belt to provide power for the flow of hydraulic oil.

[0024] The motor 13 is installed on one side of the column 3, and the hydraulic oil pump 7 is installed on the other side of the column 3, corresponding to the motor 13. The pulley of the motor 13 is connected to the pulley of the hydraulic oil pump 7 through a belt.

[0025] The working table 2 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com