Casting knife of ion membrane steel strip casting machine with opening and closing function

An ion membrane, casting machine technology, applied in the direction of coating, can solve the problem of dripping to the steel belt, etc., to achieve the effect of easy control, reduced labor, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

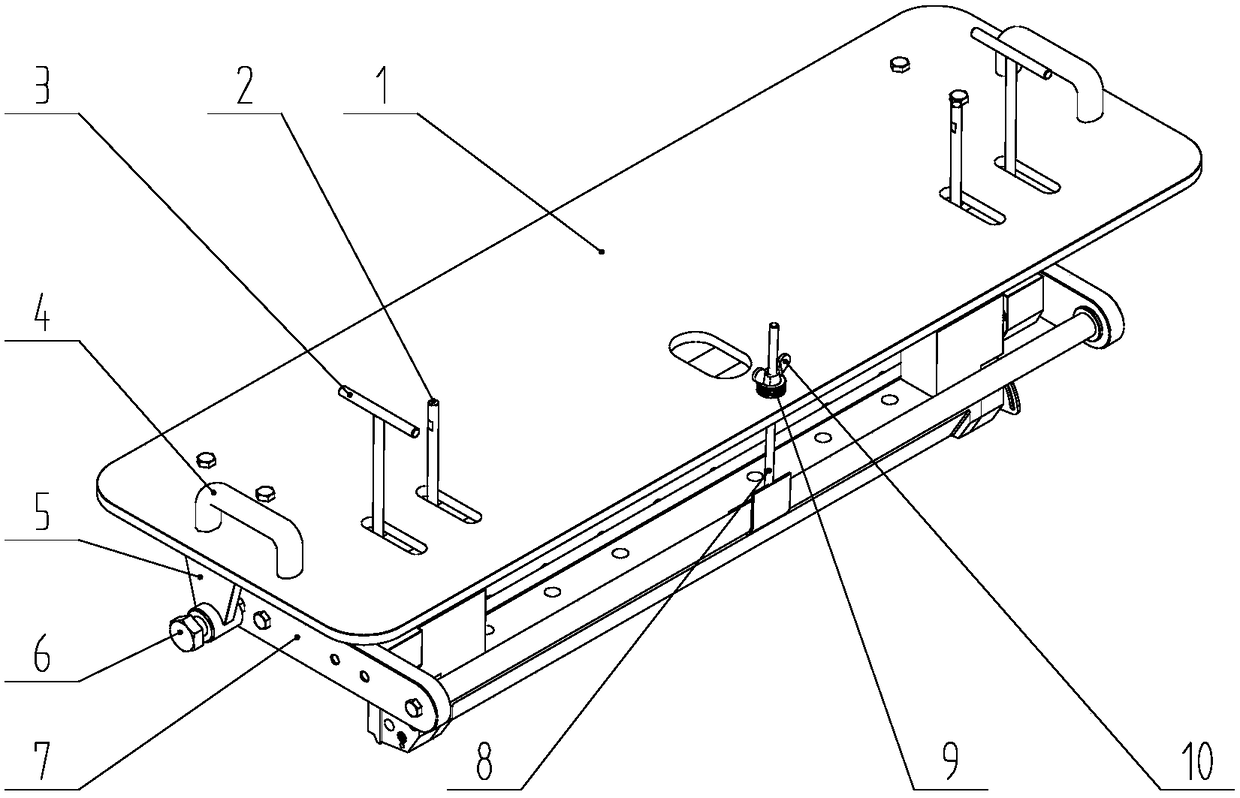

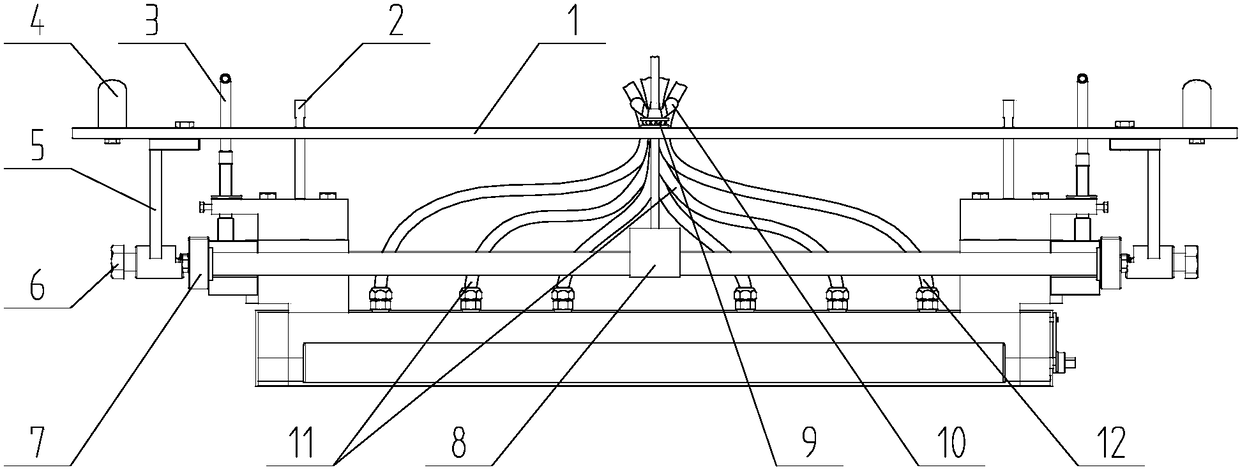

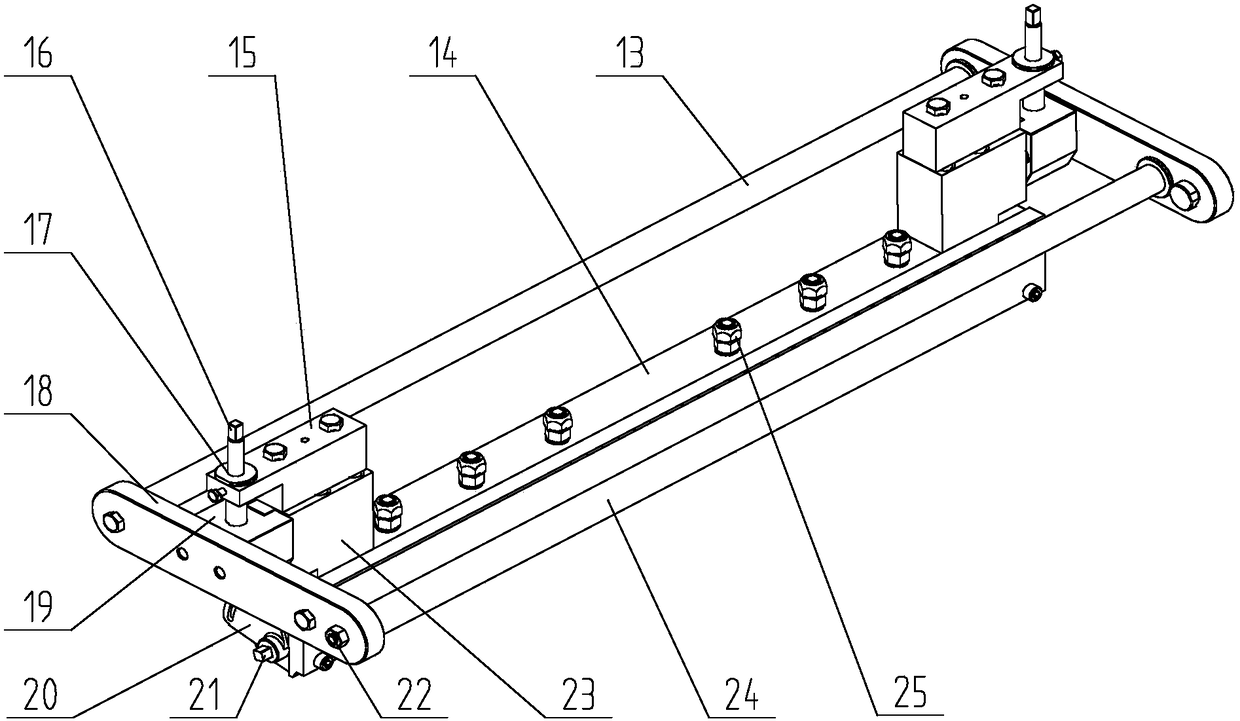

[0026] Such as Figure 1-2 As shown, the casting knife of the ionic membrane steel strip casting machine with the opening and closing function of the present invention includes a mounting plate 1, a knife setting bar 2, a fine-tuning bar 3, a hanger 5, a top wire 6, a knife rest 7, a plurality of row Air pipe 11, a plurality of feeding pipes 12 and coarse adjustment rod 8 are connected with two hangers 5 with top wires 6 under the mounting plate 1 with two handles 4, and the top is passed between the two hangers 5. The wire 6 is connected with the knife rest 7, the hook at one end of the coarse adjustment rod 8 is hooked on the crossbeam 13 of the knife rest 7, and the other end of the coarse adjustment rod 8 passes through the hole of the mounting plate 1 and stabilizes the knife rest 7 through the plane bearing 9 and the butterfly nut 10. , connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com