A box type flexographic printing unit

A flexographic printing, box-type technology, applied in printing, printing presses, rotary printing presses, etc., can solve problems affecting equipment maintenance, inconvenience, transmission leakage, etc., achieve a wide range of equipment applications, simplify mechanical transmission structure, The effect of saving process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

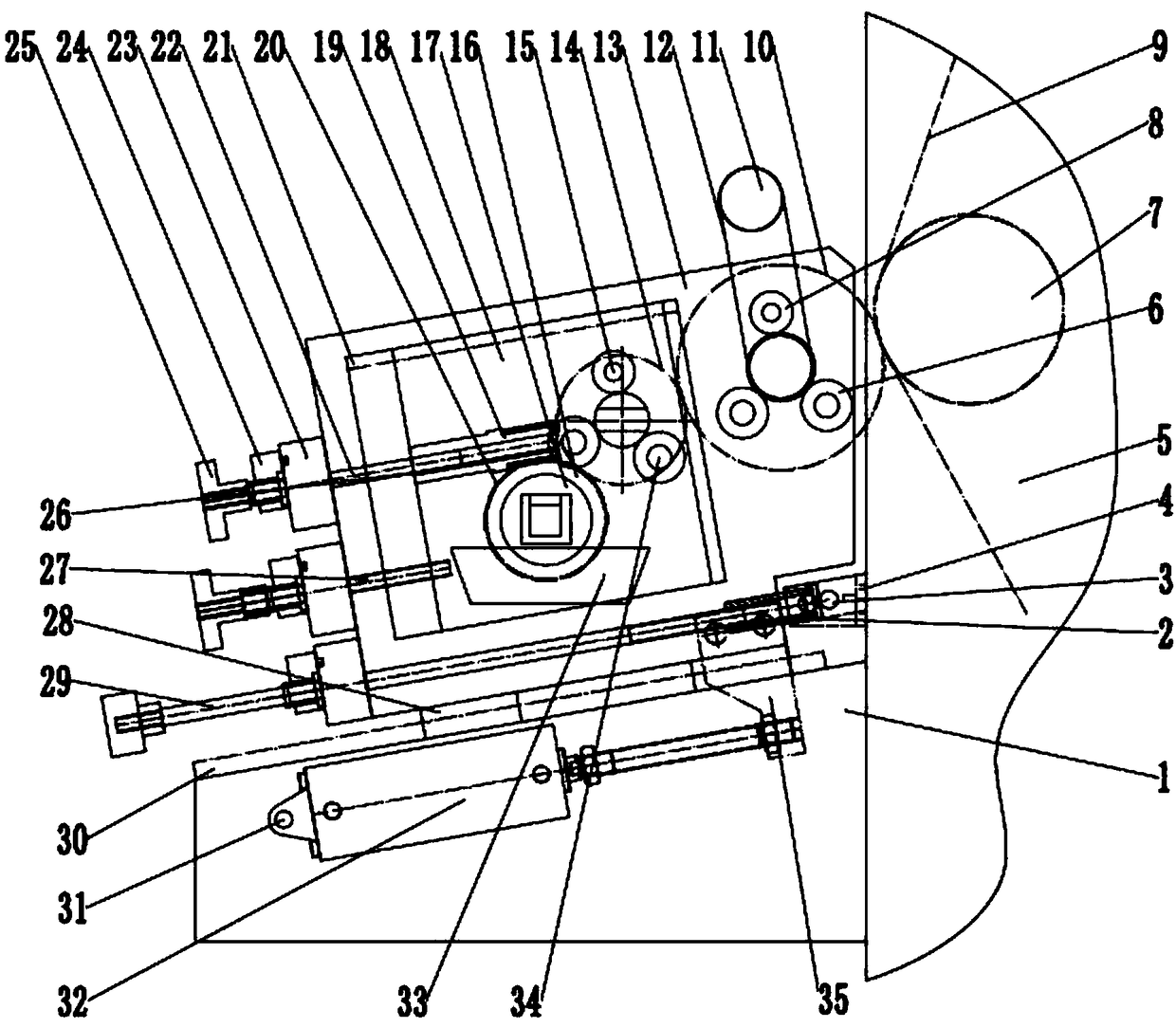

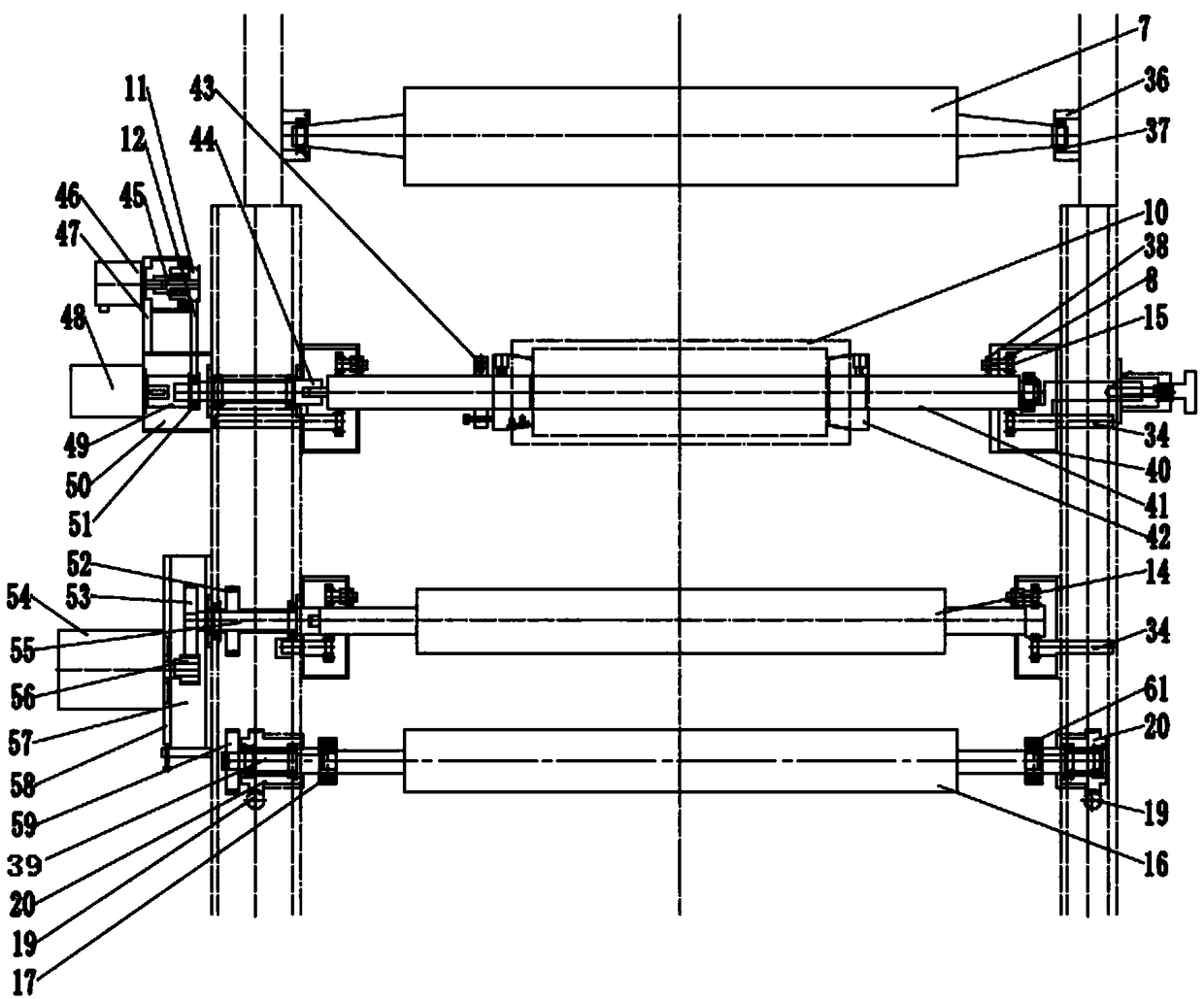

[0020] The present invention is a box-type flexographic printing unit, the structure of which is as follows: figure 1 , figure 2 As shown, it includes the bottom roller 7 installed on the large wallboards 5 on both sides. The bottom roller 7 is used as the printing platform of the material film to ensure that the material film itself is smooth and the printing quality is guaranteed. The bottom roller 7 is installed with the bottom roller bearing 37 The bottom roller bearing housing 36 on the large wall panels 5 on both sides is connected, and the large wall panels 5 on both sides are the frame of the whole device, and the large wall panels 5 are connected with the lower wall panels 1 as a whole, which is the basis for carrying the device.

[0021] The lower wallboard 1 is also provided with an upper box body 13, the bottom of the upper box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com