A kind of laser anti-counterfeiting material and its processing technology for medicine packaging

A laser anti-counterfeiting and pharmaceutical technology, used in radiation-absorbing coatings, layered products, lamination devices, etc., can solve the problems of wrapping paper that cannot be kept in the dark, unclean peeling, and incomplete film transfer. Achieve the effect of being suitable for market promotion, high yield and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A kind of anti-counterfeiting laser material for medicine packaging, comprising an outer protective layer, an anti-counterfeiting laser layer, an aluminum foil layer, a backing paper layer, a cardboard layer and a light-shielding material layer, and the anti-counterfeiting laser layer is attached to the aluminum foil layer On the glossy surface of the aluminum foil layer, the outer protective layer is a transparent layer, coated on the surface of the laser anti-counterfeiting layer, the backing paper layer is attached to the matte surface of the aluminum foil layer, and the cardboard layer is attached to the The outer surface of the backing paper layer, the light-shielding material layer is coated on the outer surface of the cardboard layer;

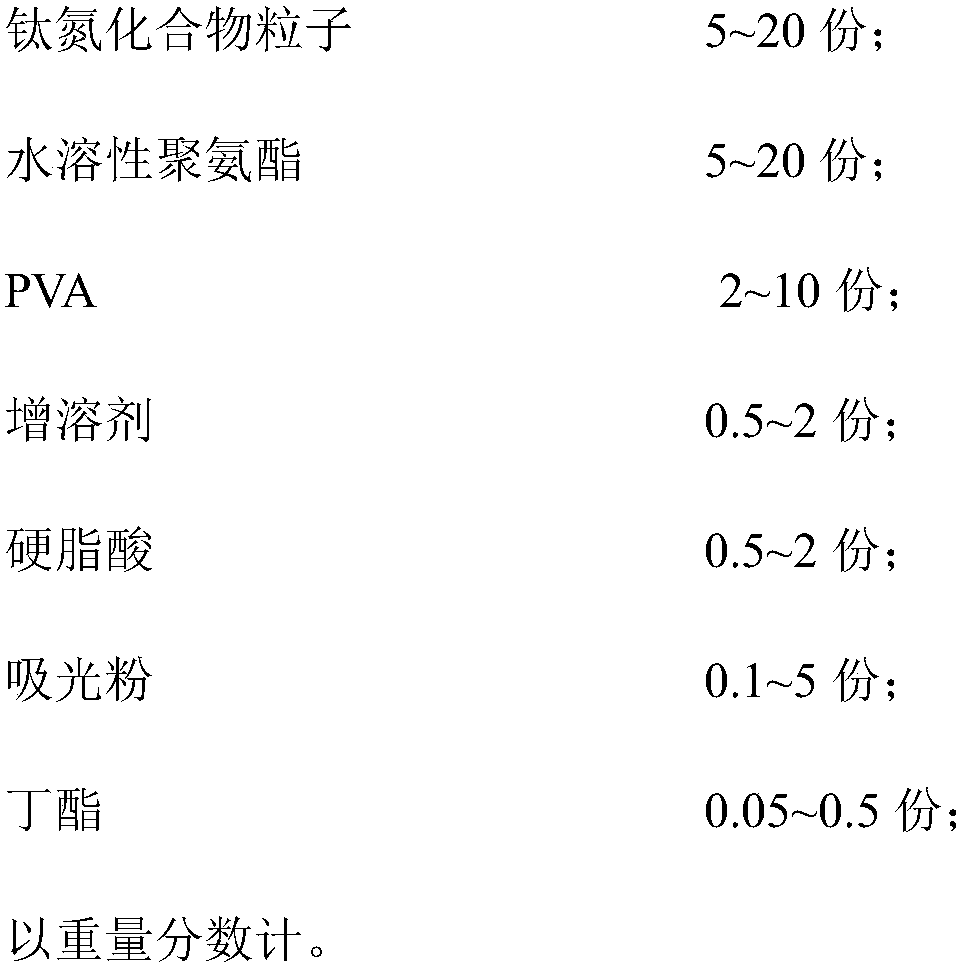

[0023] The shading material layer includes the following components:

[0024]

[0025] The above-mentioned processing technology of the laser anti-counterfeiting material used for pharmaceutical packaging comprise...

Embodiment 2

[0036] Embodiment 2: This product structure is identical with embodiment 1, and its difference is:

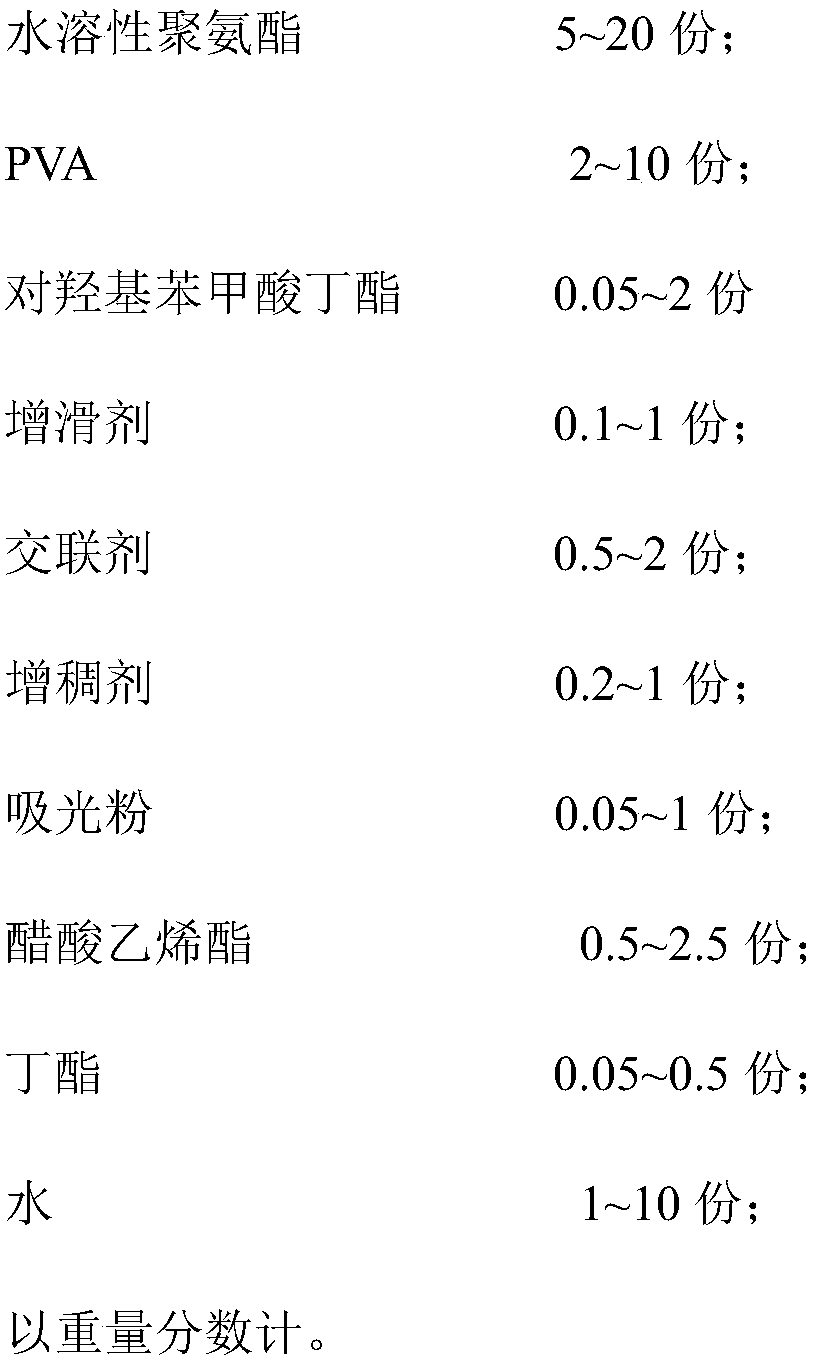

[0037] The shading material layer includes the following components:

[0038]

[0039]

[0040] The above-mentioned processing technology of the laser anti-counterfeiting material used for pharmaceutical packaging comprises the following steps:

[0041] (1) Coat the water-based laser transfer coating on the BOPP film at a coating speed of 30m / min, then introduce it into an oven, and dry it at 170°C at a drying speed of 30m / min;

[0042] (2) The BOPP film coated with the water-based laser transfer coating is molded by a molding machine to obtain a laser film;

[0043] (3) Coat the matte surface of the aluminum foil with an adhesive layer and compound it with the lining paper layer to obtain aluminum foil paper, and after being heated by a hot pressing roller, it is transported by several tension rollers, and then coated with an adhesive layer on the outer surface of the l...

Embodiment 3

[0052] Embodiment 3: this product structure is identical with embodiment 1, and its difference is:

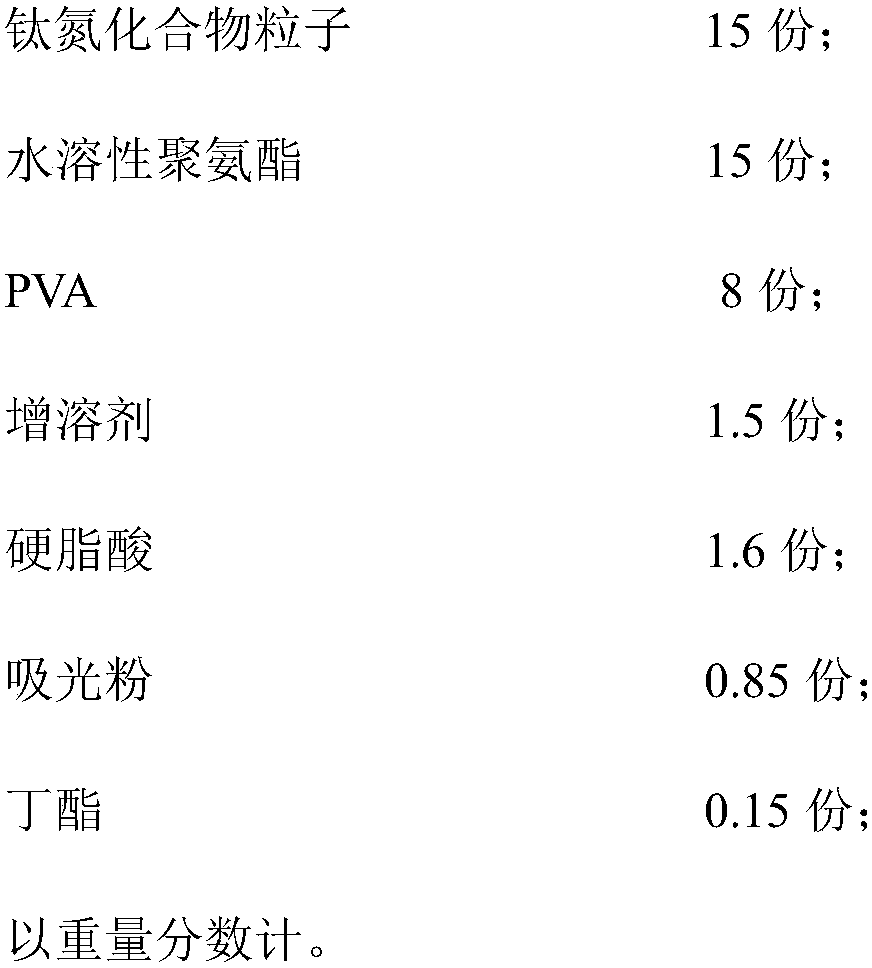

[0053] The shading material layer includes the following components:

[0054]

[0055] The above-mentioned processing technology of the laser anti-counterfeiting material used for pharmaceutical packaging comprises the following steps:

[0056](1) Coat the water-based laser transfer coating on the BOPP film at a coating speed of 10m / min, then introduce it into an oven, and dry it at 160°C with a drying speed of 25m / min;

[0057] (2) The BOPP film coated with the water-based laser transfer coating is molded by a molding machine to obtain a laser film;

[0058] (3) Coat the matte surface of the aluminum foil with an adhesive layer and compound it with the lining paper layer to obtain aluminum foil paper, and after being heated by a hot pressing roller, it is transported by several tension rollers, and then coated with an adhesive layer on the outer surface of the lining paper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com