Bamboo particle processing feed bin

A technology of feeding silo and silo, applied in sustainable manufacturing/processing, sustainable packaging industry, containers, etc., can solve the problems of poor powder feeding, troublesome processing and production, blockage, etc. The effect of unobstructed feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

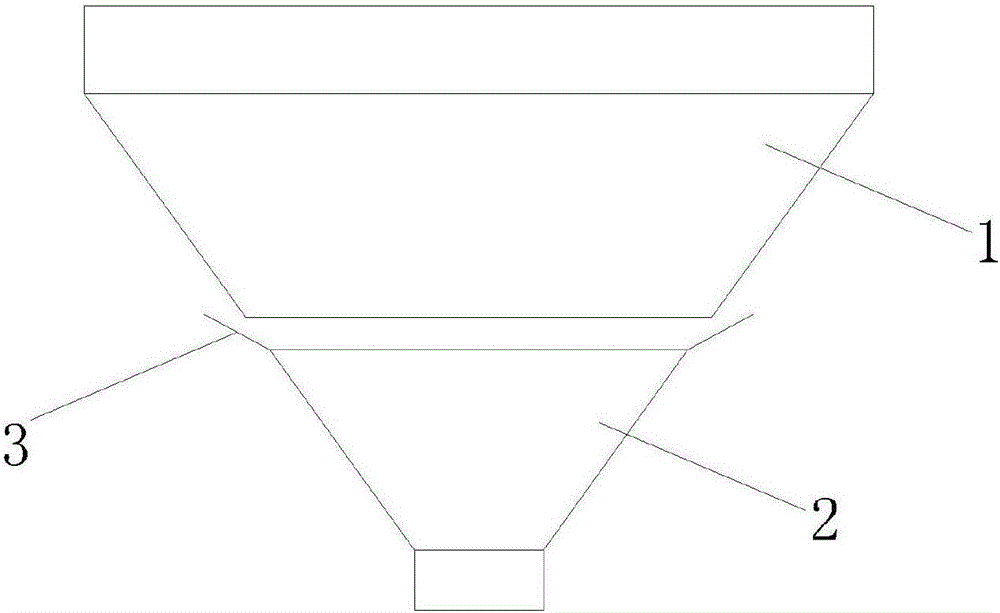

[0008] see figure 1 , the specific embodiment of the present invention adopts the following technical solutions: it includes an upper hopper 1 and a lower hopper 2, the upper hopper 1 and the lower hopper 2 are all tapered, the upper inlet is large, and the lower outlet is small. The entrance of silo 1 is connected to the feeding machine. There is a lower silo 2 under the upper silo 1. There is a certain gap between the upper silo 1 and the lower silo 2. A ring stop is welded on the edge of the entrance of the lower silo 2. Plate 3, the opening of the baffle 3 is larger than the outlet of the upper hopper 1, and the height of the baffle 3 is slightly higher than the outlet of the upper hopper 1, and the outlet of the lower hopper 2 is connected with the extrusion molding machine.

[0009] When feeding, the raw material powder is put into the feed bin from the feeder through the inlet of the upper bin, then put into the inlet of the lower bin through the outlet of the upper bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com