Plunger type oil diaphragm pump

A diaphragm pump and plunger technology, applied in the field of plunger oil diaphragm pump, can solve the problems of difficult operation, troublesome adjustment of three valves, leakage of methanol, etc., to achieve low friction power consumption, superior sealing conditions and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

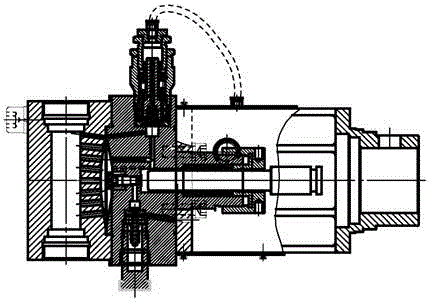

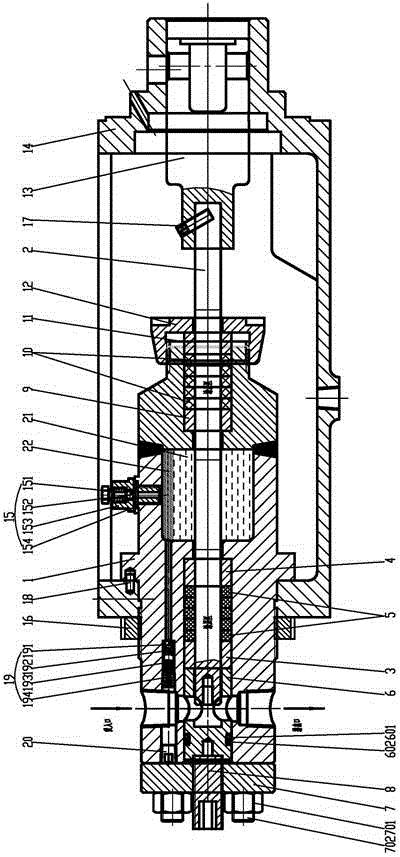

[0021] Such as image 3 The plunger type oil diaphragm pump shown includes a fluid end and a power end, wherein the fluid end includes: a hydraulic cylinder bracket 14; a crosshead 13, a positioning screw pin 17, a plunger 2; an adjusting nut 12, and an auxiliary pressure ring 11. Auxiliary packing 10, auxiliary guide sleeve 9; engine oil 21, medium (methanol) 22; manual air release valve assembly 15: air release plug 151, valve ball 152, valve chamber 153, gasket 154; pump body 1, cylindrical pin 18. Lock nut 16; return valve assembly 19: valve ball 191, valve cover 192, valve spring 193, screw plug bracket 194, screw plug 20; main pressure ring 4, main packing 5, main guide sleeve 3, pressure sleeve 6 , O-ring 601, retaining ring 602, adjusting bolt 8, flange 7, hex nut 701, stud 702.

[0022] The hydraulic cylinder bracket 14 is assembled with the power end fuselage for fixing the entire liquid end.

[0023] The pump body 1 is provided with a plunger passage and a valve g...

Embodiment 2

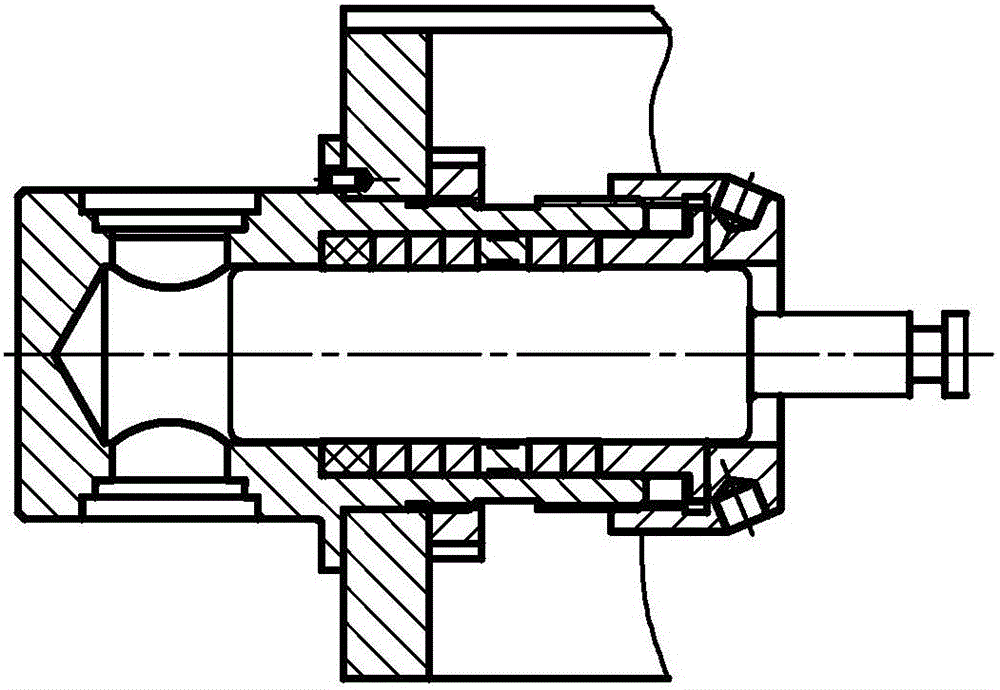

[0030] The difference from Embodiment 1 is that due to the difference in the medium, the position of the return valve cavity is set on the lower side of the pump body 1, the corresponding suction port is at the bottom, and the discharge port is at the top, see Figure 4shown. Specifically, the density of the conveying medium in this embodiment is higher than that of the engine oil 21, so the medium will sink below the engine oil 21, and the leaked medium will slowly fill the remaining cavity of the entire oil pool. When the pressure in the cavity is greater than 1 MPa, the return flow located below The valve assembly 19 will be opened, and the medium below the machine oil 21 will flow into the suction port through the return valve assembly 19 and be released to a certain amount. When the pressure in the chamber is less than 1 MPa, the return valve assembly 19 will automatically close. Since the pressure in the chamber is always less than 1MPa, the leakage of the auxiliary stuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com