Flat-plate solar heat collector production method

A flat-panel solar energy and production method technology, which is applied in the directions of solar thermal collectors, thermal insulation of solar thermal collectors, solar thermal collectors using working fluid, etc. To solve problems such as all sealing and loose connection at the joints, to increase the thermal insulation effect, reduce potential safety hazards, and improve the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

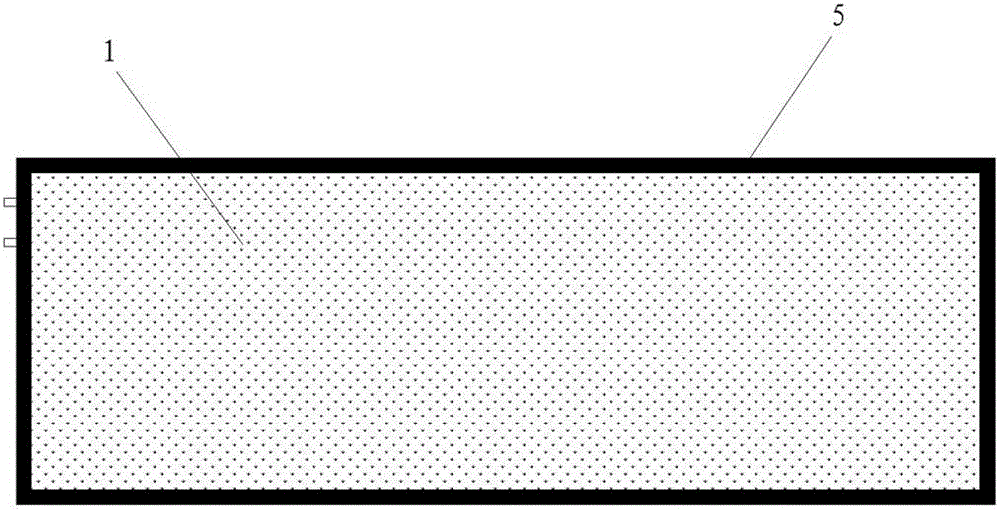

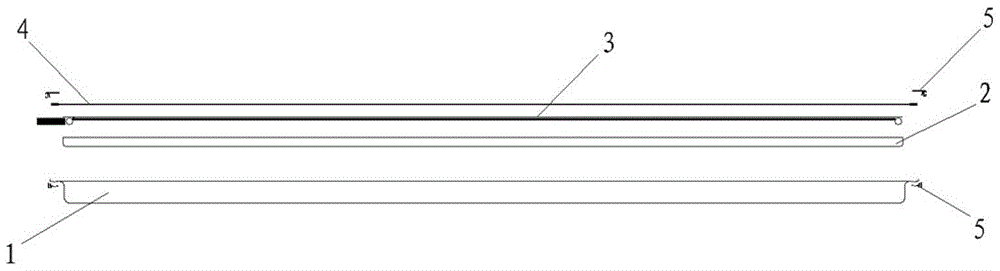

[0017] refer to Figure 1-2 , the product produced by the method of the present invention includes a backboard 1, an insulating layer 2, a heat collecting layer 3, and a tempered glass 4. The backboard 1 is made of aluminum or galvanized material, and is formed by one-time stamping, and an insulating layer is arranged above the backboard 1. 2. The thermal insulation layer 2 is formed by one-time high-pressure foaming of polyurethane, and a heat collection layer 3 is arranged on the top of the thermal insulation layer 2. The heat collection layer 3 is formed by laser welding of copper tube flow and heat collection film copper tube, and heat collection A toughened glass 4 is arranged on the top of the layer 3, and the toughened glass 4 is a cloth-grained tempered glass of 3 mm. The junction of the toughened glass 4 and the back panel 1 is edged with rubber, and the back panel 1 and the toughened glass 4 are buckled by side strips 5 One-time stamping for locking.

[0018] Follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com