Medicinal material drying device in the pharmaceutical process

A drying device and technology for medicinal materials, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of cumbersome extraction of medicinal materials, and achieve the effect of increasing drying speed, improving efficiency, and sufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

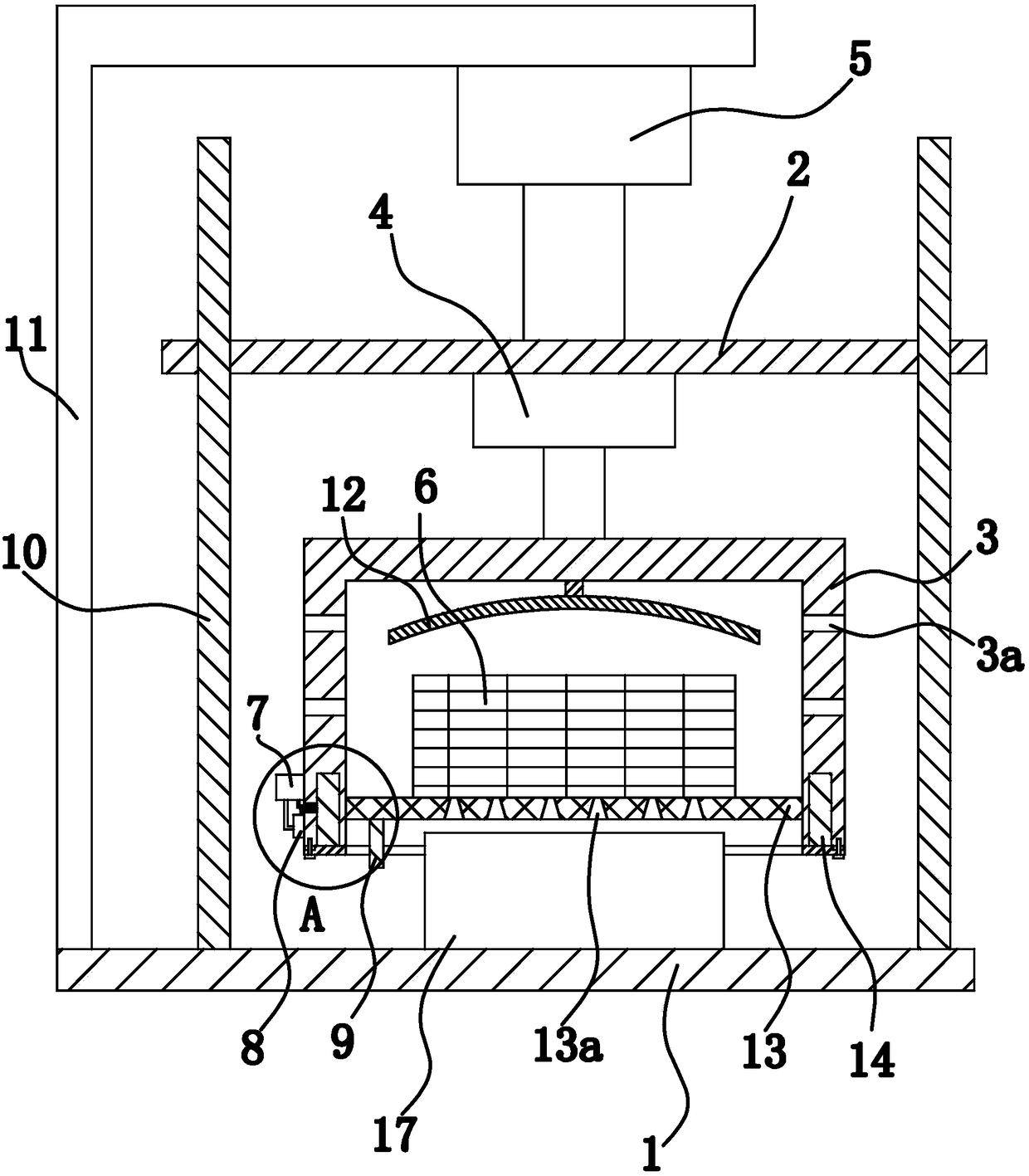

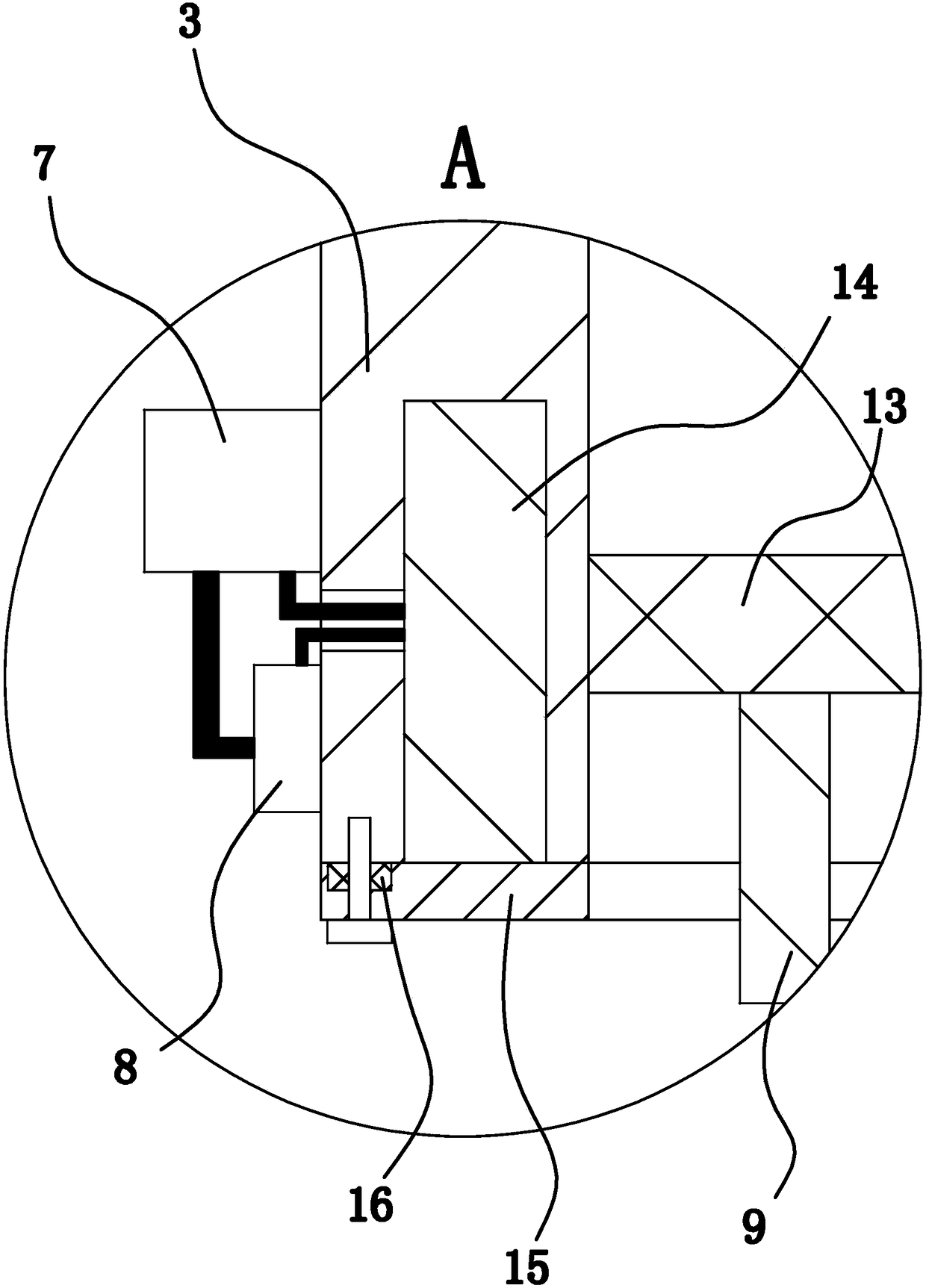

[0027] Such as figure 1 As shown, the medicinal material drying device in this pharmaceutical process consists of a workbench 1, a connecting plate 2, a drum 3, a motor 4, a cylinder 5, a grid box 6, a support plate 13, a battery 7, a switch 8, a pull rod 9, and a bracket 11, baffle plate 12, warm air blower 17 etc. are formed. Wherein, both the support plate 13 and the rotating drum 3 are made of magnetically permeable materials, and the magnetically permeable materials can be stainless steel, iron and the like. In this embodiment, preferably, both the support plate 13 and the drum 3 are made of stainless steel.

[0028] Specifically, two guide rods 10 are vertically fixed on the workbench 1; the connecting plate 2 is horizontally arranged on the workbench 1, and the connecting plate 2 is vertically penetrated with two guide holes, and the two guide holes connect with the two guide holes. The guide rods 10 are facing one by one, and the two guide rods 10 pass through the tw...

Embodiment 2

[0036] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the lower end of the drum 3 is covered with a sealing cylinder, and the sealing cylinder is fixed to the drum 3 through a threaded structure. There is a ring-shaped protruding sealing part on the inner side wall of the lower end of the sealing cylinder, and the sealing part closes the notch of the groove by the way that the upper end surface of the sealing part abuts against the lower end surface of the drum 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com