Radiator built-in plate-fin oil cooler

A technology for oil coolers and radiators, which is applied in the field of automotive powertrain cooling systems, can solve the problems of oil cooler joints occupying radiator water chambers, and increase the external boundary conditions of oil coolers, so as to reduce oil resistance, The water chamber is small in size and has the effect of increasing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

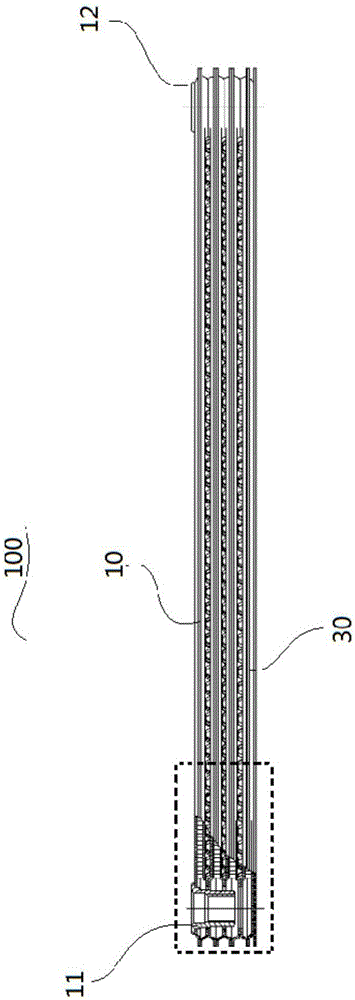

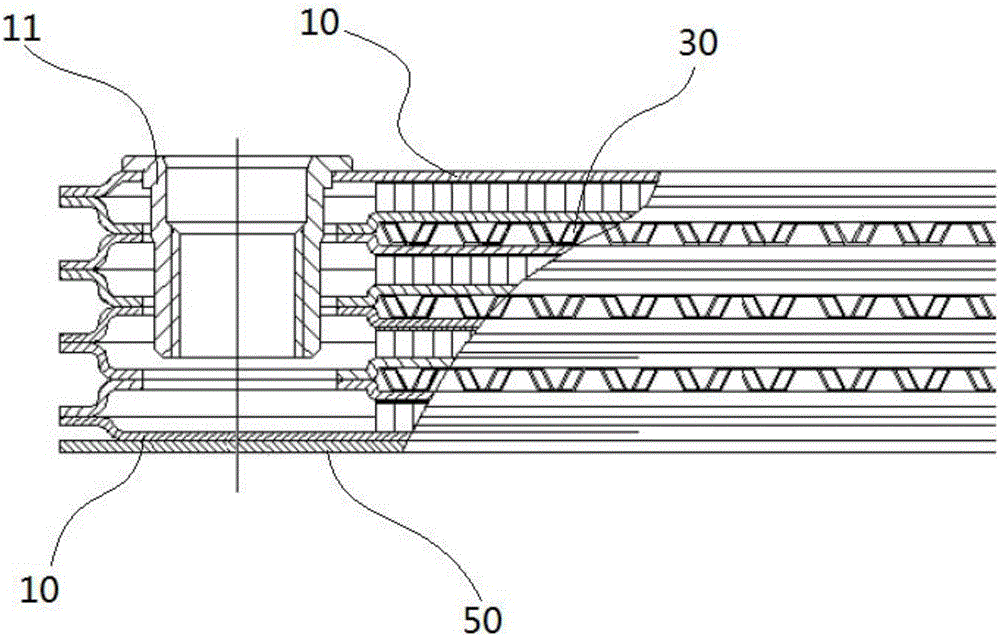

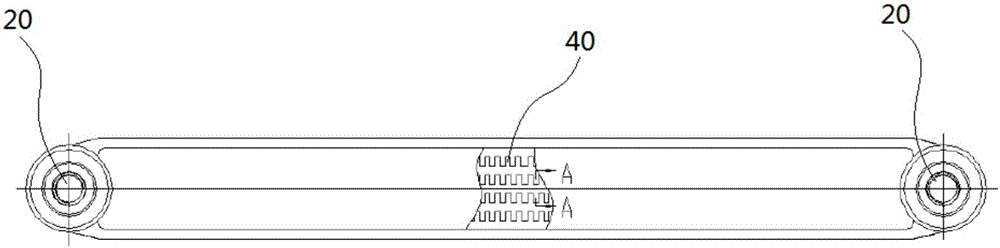

[0036] see figure 1 , which shows a plate-fin oil cooler 100 with a built-in radiator according to an embodiment of the present invention. The oil cooler 100 includes an oil collection chamber (not shown), specifically, in combination with Figure 1 to Figure 4 As shown, the oil cooler 100 also includes at least two radiating plates 10 and oil cooler joints 20, and all the radiating plates 10 in the at least two radiating plates 10 are connected to the oil collection chamber, and the oil cooler joints 20 are respectively arranged on At the two ends of all heat dissipation plates 10, at least two heat dissipation plates 10 are all arranged in the water chamber of the radiator, and at least one row of fins 30 is arranged between adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com