Fluorescence Intensity Measurement Method for Automatic Magnetic Particle Inspection

A technology of fluorescence intensity and magnetic particle flaw detection, which is applied in the field of fluorescence intensity measurement, can solve the problems of lack of online detection of fluorescence intensity, and achieve the effect of avoiding human error and accurate fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

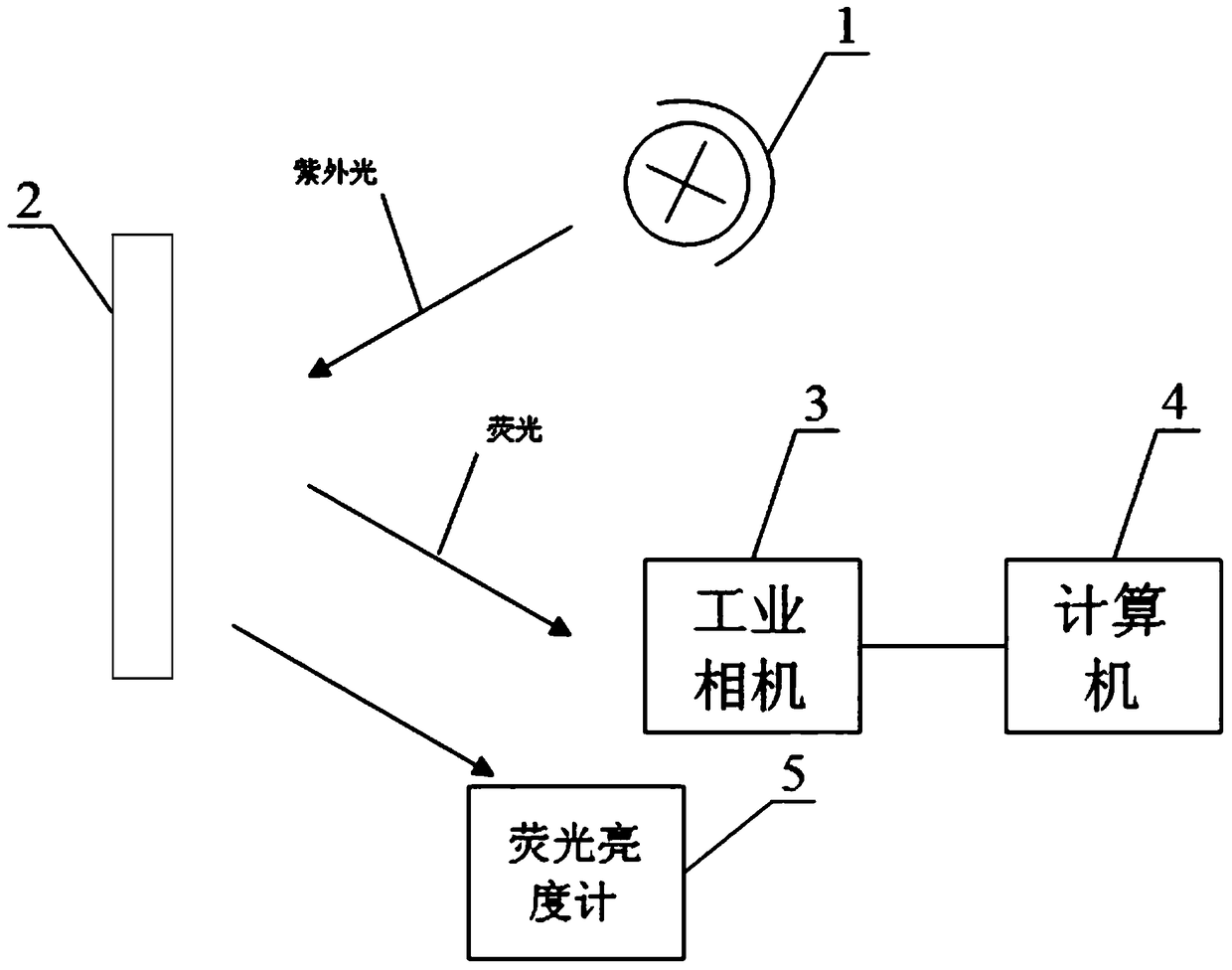

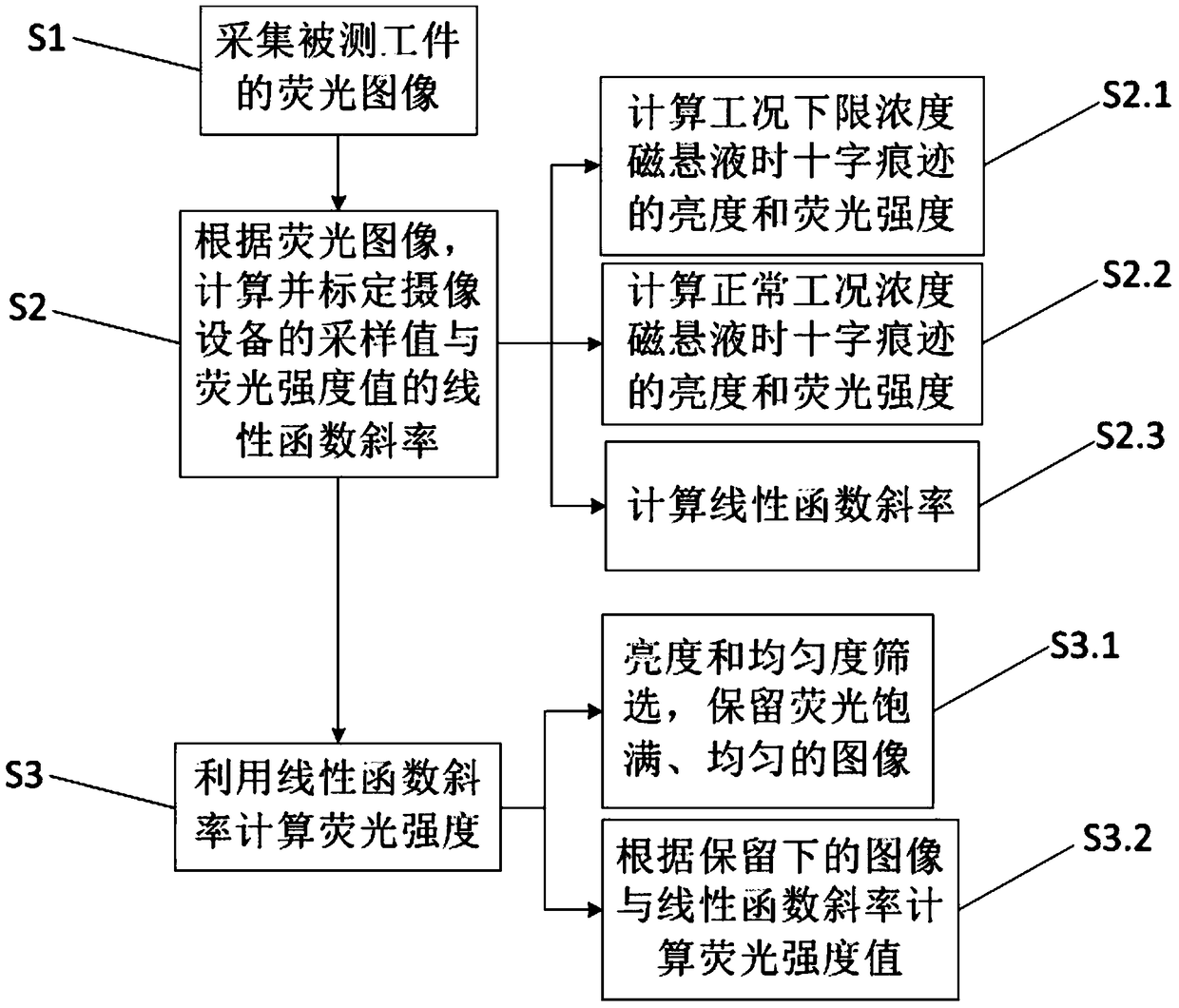

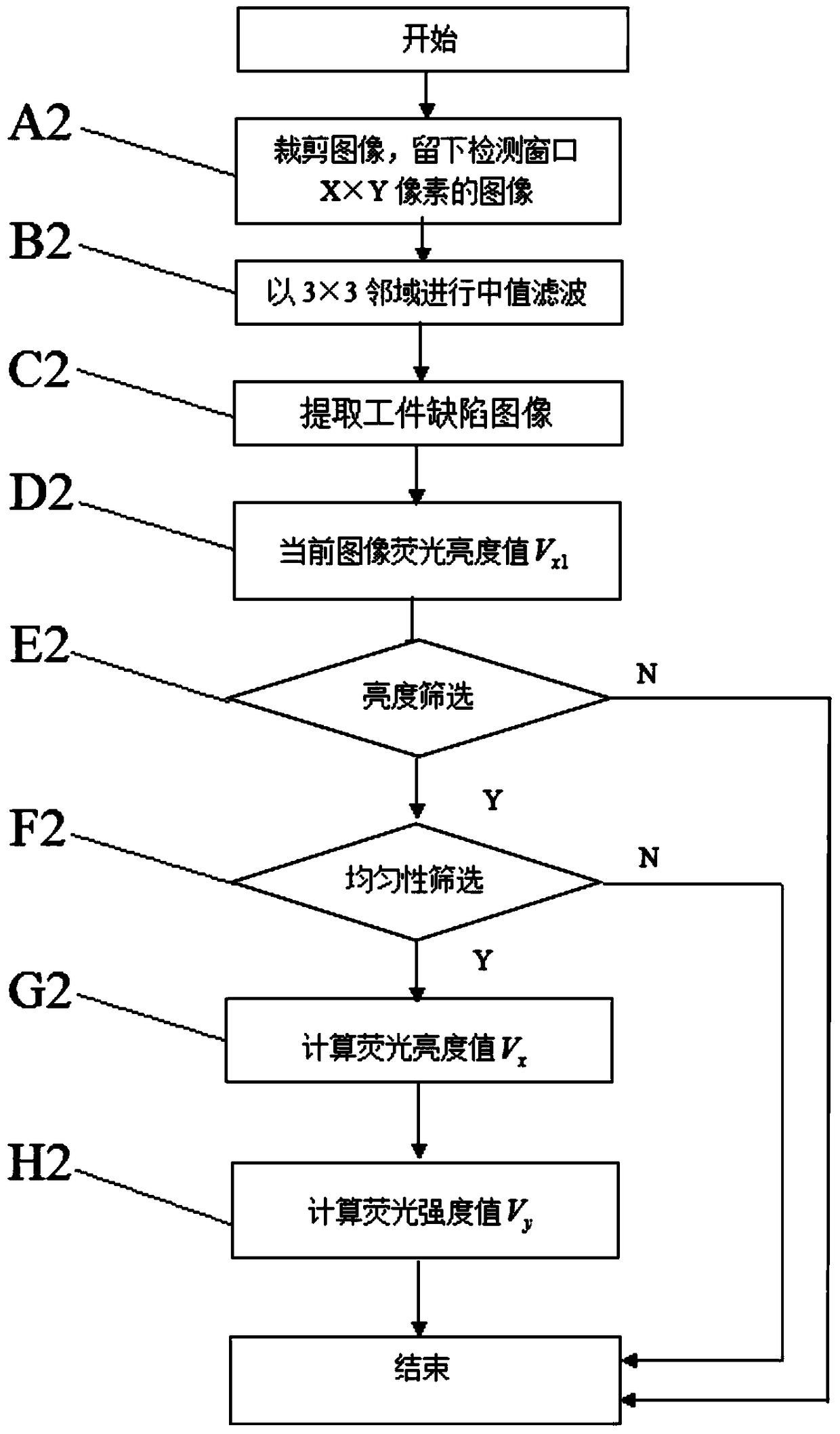

[0024] refer to figure 1 , the present invention first discloses a fluorescence intensity measuring device for automatic magnetic particle flaw detection, which mainly includes an ultraviolet light source 1, an imaging device 3, a computer 4, a fluorescence luminance meter 5, and a sensitivity test piece (not shown in the figure). In the imaging device 3 of the present invention, the imaging device is an industrial CCD camera, but it is not limited thereto.

[0025] Such as figure 1 As shown, when the ultraviolet light source 1 irradiates the workpiece 2 to be measured, the imaging device 3 takes a fluorescent image of the workpiece 2 to be measured, and transmits the fluorescent image to the computer 4 . The sensitivity test piece is placed on the workpiece 2 to be tested and includes a cross mark, and the fluorescence lumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com