Photoresist removal method and semiconductor device manufacturing method

A photoresist and semiconductor technology, used in semiconductor/solid-state device manufacturing, electrical components, photosensitive material processing, etc., can solve problems such as reducing the stability of semiconductor devices, difficult to completely remove photoresist, and decreasing product yield. Solve the problem of photoresist residue, speed up the removal rate and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose and features of the present invention more obvious and understandable, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

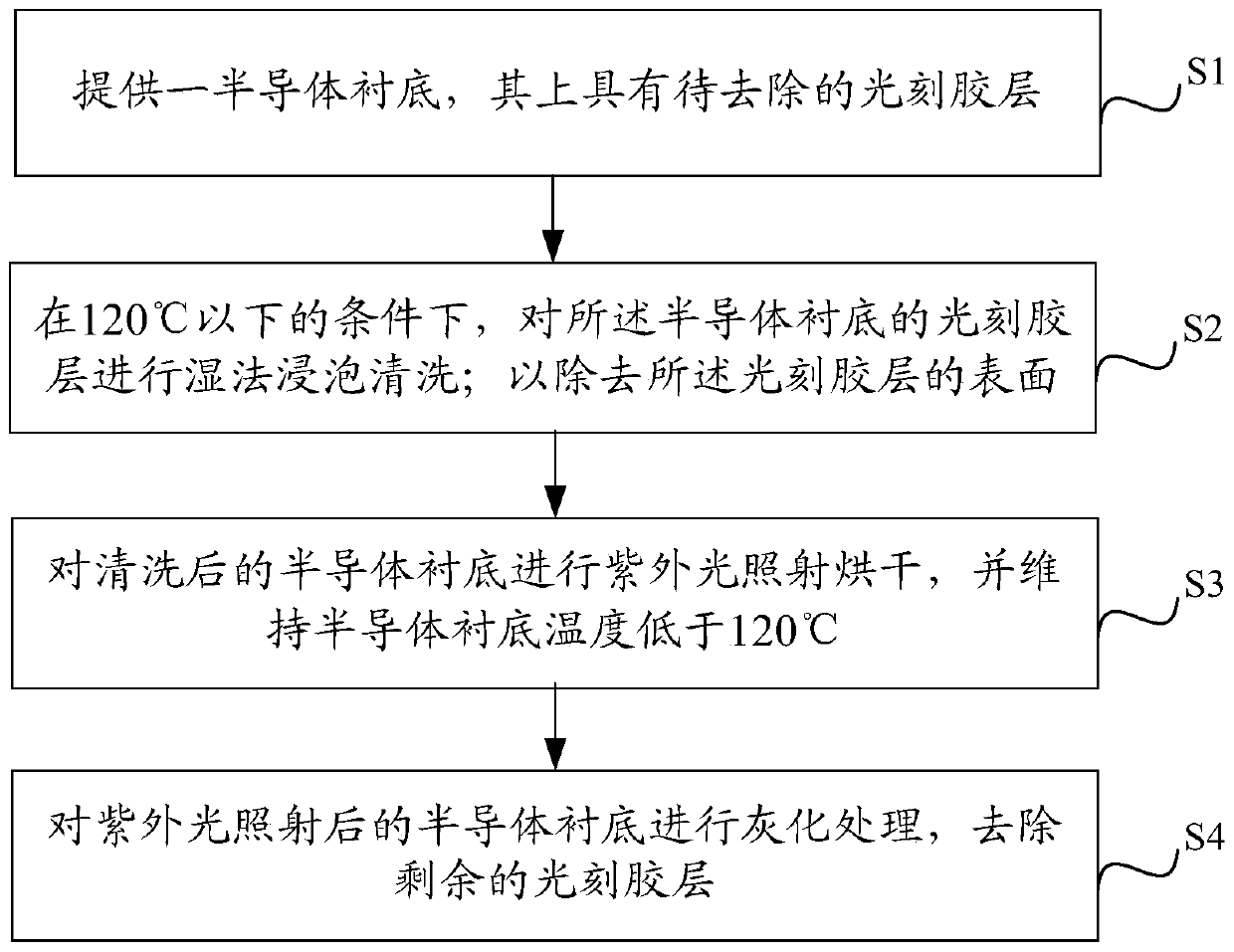

[0035] Please refer to figure 2 , the present invention proposes a photoresist removal method, comprising:

[0036] S1, providing a semiconductor substrate with a photoresist layer to be removed thereon;

[0037] S2, under the condition of below 120°C, perform wet immersion cleaning on the photoresist layer of the semiconductor substrate; to remove the surface of the photoresist layer;

[0038] S3, irradiating and drying the cleaned semiconductor substrate with ultraviolet light, and maintaining the temperature of the semiconductor substrate below 120°C;

[0039] S4, performing ashing treatment on the semiconductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com