Gas discharge tube

A gas discharge tube and electrode technology, applied in gas discharge tube, discharge tube, gas discharge lamp parts and other directions, can solve the problems of explosion, affect safe use, short circuit of gas discharge tube, etc., and achieve good overvoltage and overcurrent The effect of protective properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

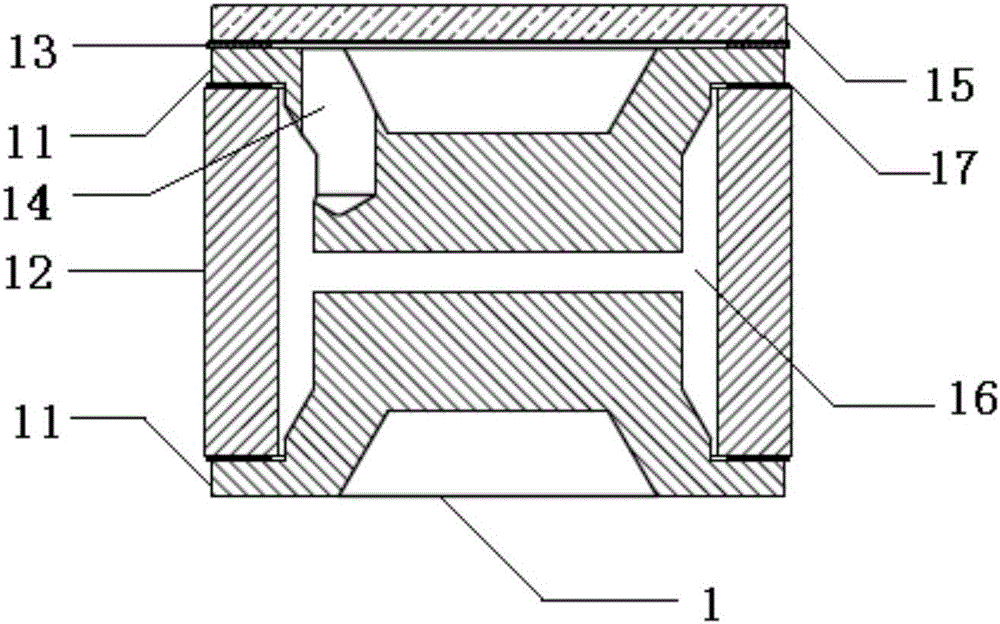

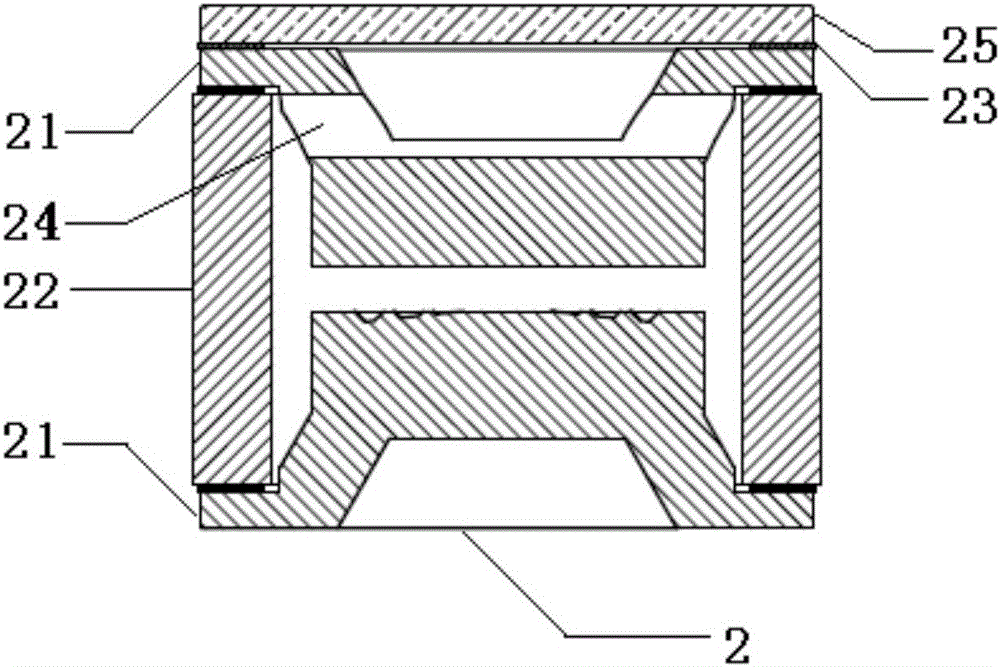

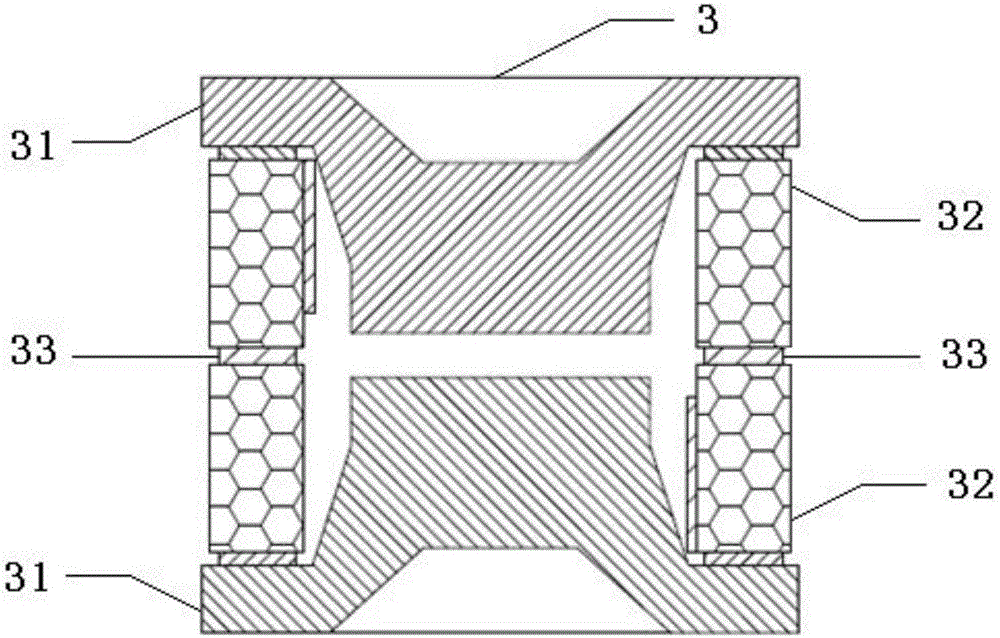

[0039] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings. It should be explained in advance that the high-temperature solder referred to in the present invention refers to the solder whose melting point is greater than 500°C, and the high temperature refers to a temperature greater than 500°C; the low temperature referred to in the present invention is a lower temperature than the high temperature, which is 500°C and a temperature below 500°C; the low-temperature sealing adhesive referred to in the present invention refers to a sealing material that can withstand low temperatures, and the material will melt, deform or even liquefy in an environment higher than the above-mentioned low temperature, resulting in failure to seal; The insulating tube body is a glass tube, a porcelain tube or other insulating tubes suitable for the material of the gas discharge tube; the gas discharge tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com