Method and apparatus for non-contact measurement of internal quantum efficiency in light emitting diode structures

A technology for light-emitting diodes and luminescence measurement, which is used in diode testing, measuring devices, electrical excitation analysis, etc., and can solve problems such as high contact resistance, difficult alignment measurement artifacts, blocked electroluminescence, and inability to consider lateral currents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

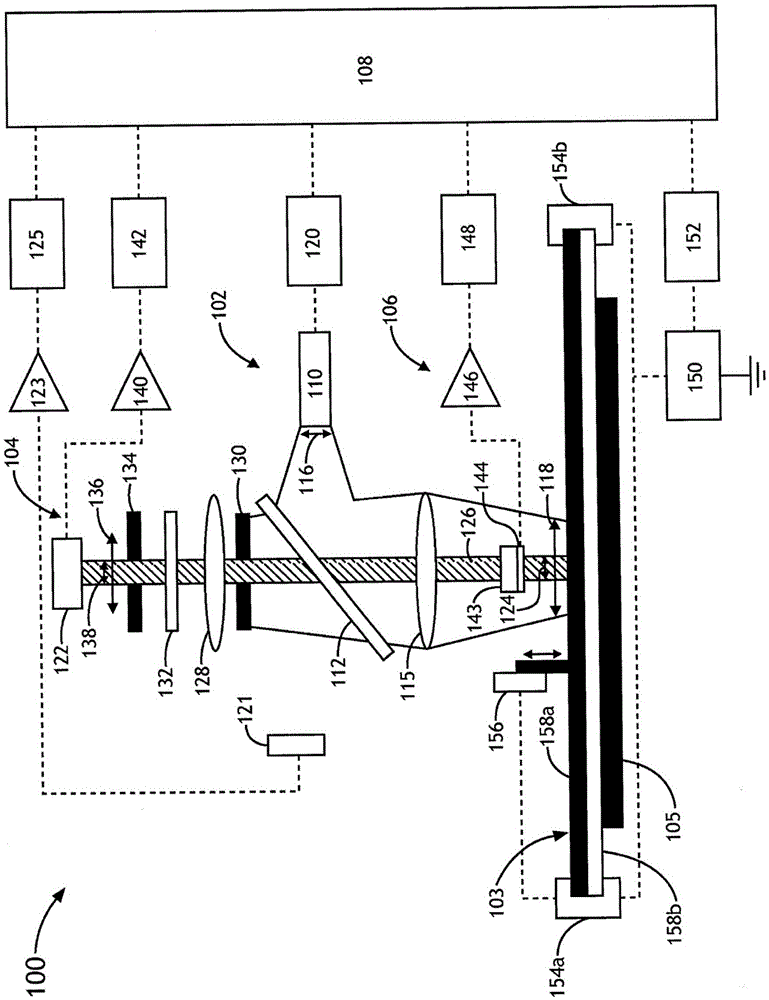

[0039] Reference will now be made in detail to the disclosed subject matter, which is illustrated in the accompanying drawings.

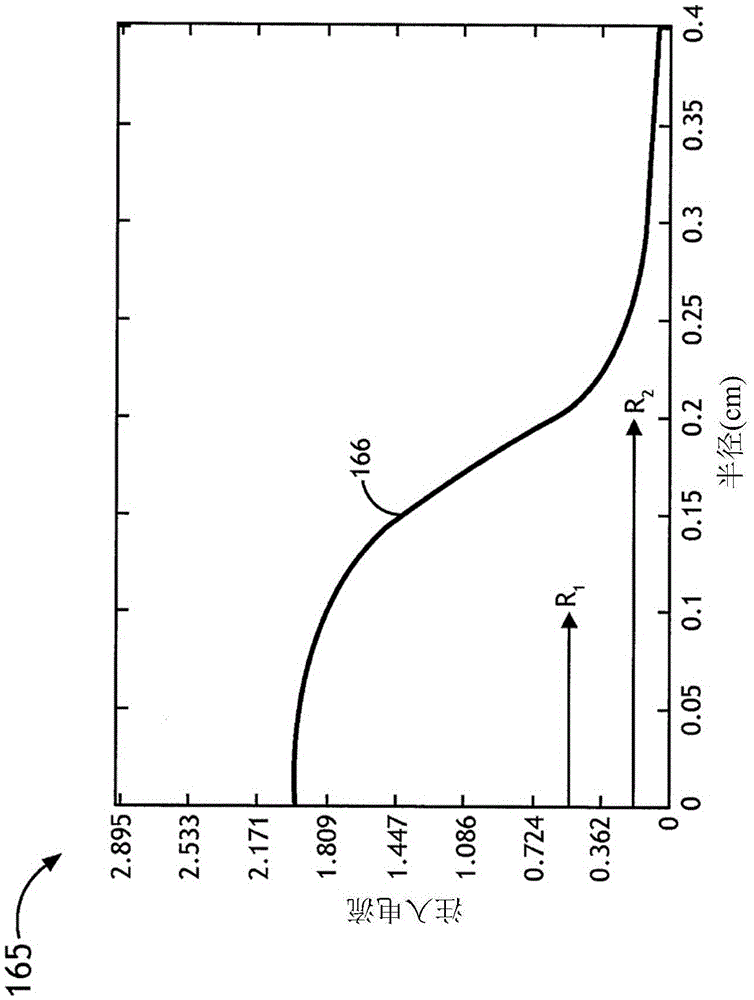

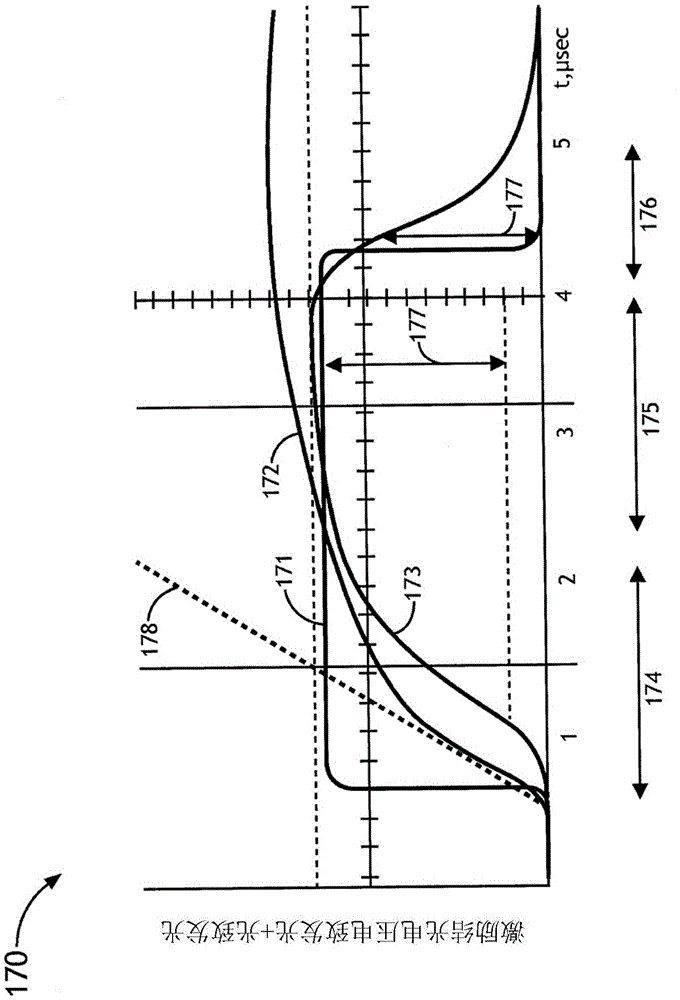

[0040] generally refer to Figures 1A to 4C , describe systems and methods for non-contact measurement of one or more characteristics of light emitting diode (LED) structures in accordance with the present invention. Embodiments of the invention relate to a luminescence measurement technique suitable for measuring electroluminescence (EL) responses and / or photoluminescence (PL) responses from LED structures illuminated by excitation illumination. In addition, embodiments of the present invention relate to a non-contact junction photovoltage ( JPV) technology.

[0041] The non-contact measurement techniques described throughout this disclosure provide accurate measurements of one or more characteristics of LED structures. In some embodiments, the non-contact measurement techniques of the present invention can provide, but are not limited to, monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com