Five-axis false tooth processing machine tool

A technology for processing machine tools and dentures, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems that dust and liquid cannot enter the processing machine tool, and the three linear axes are violated, so as to ensure the accuracy and life, and good quality. The effect of protective measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

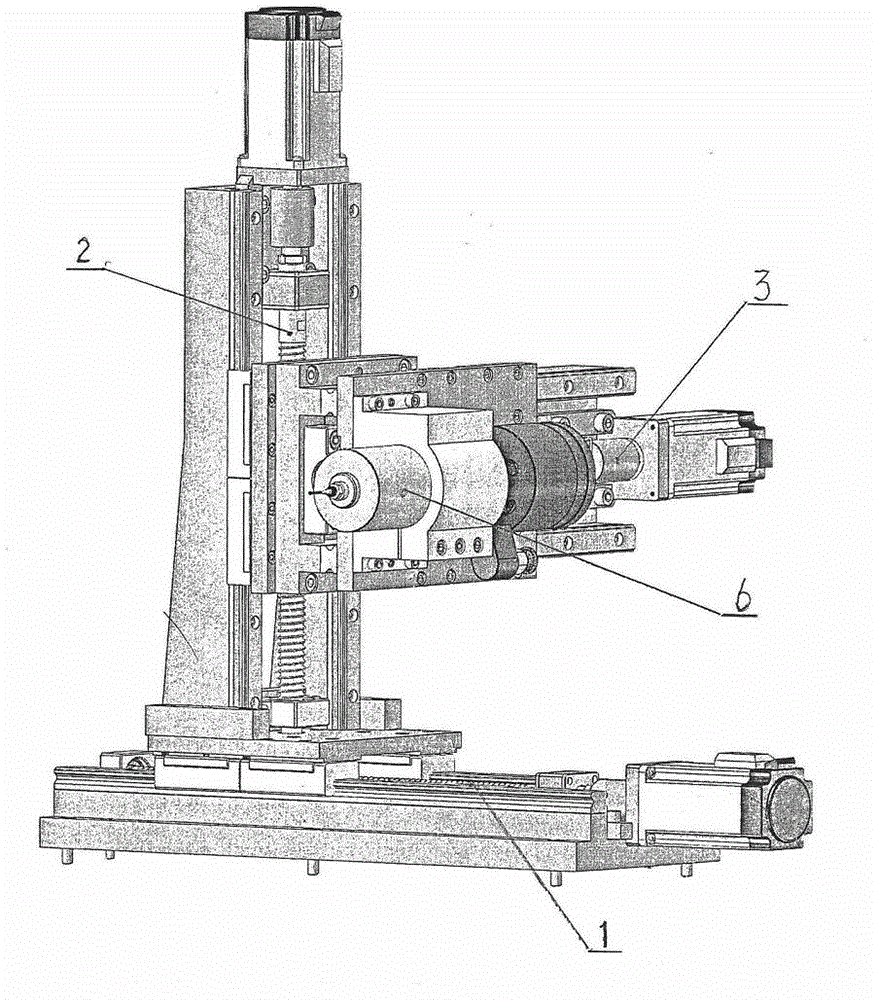

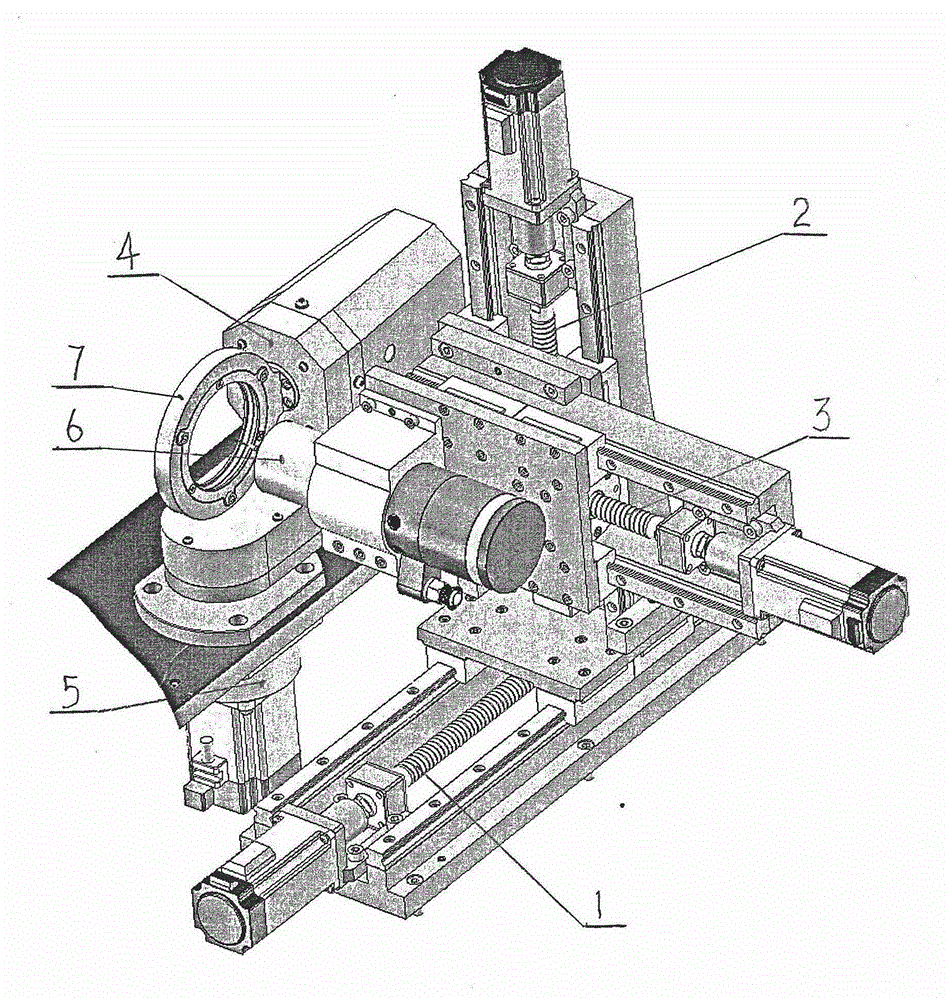

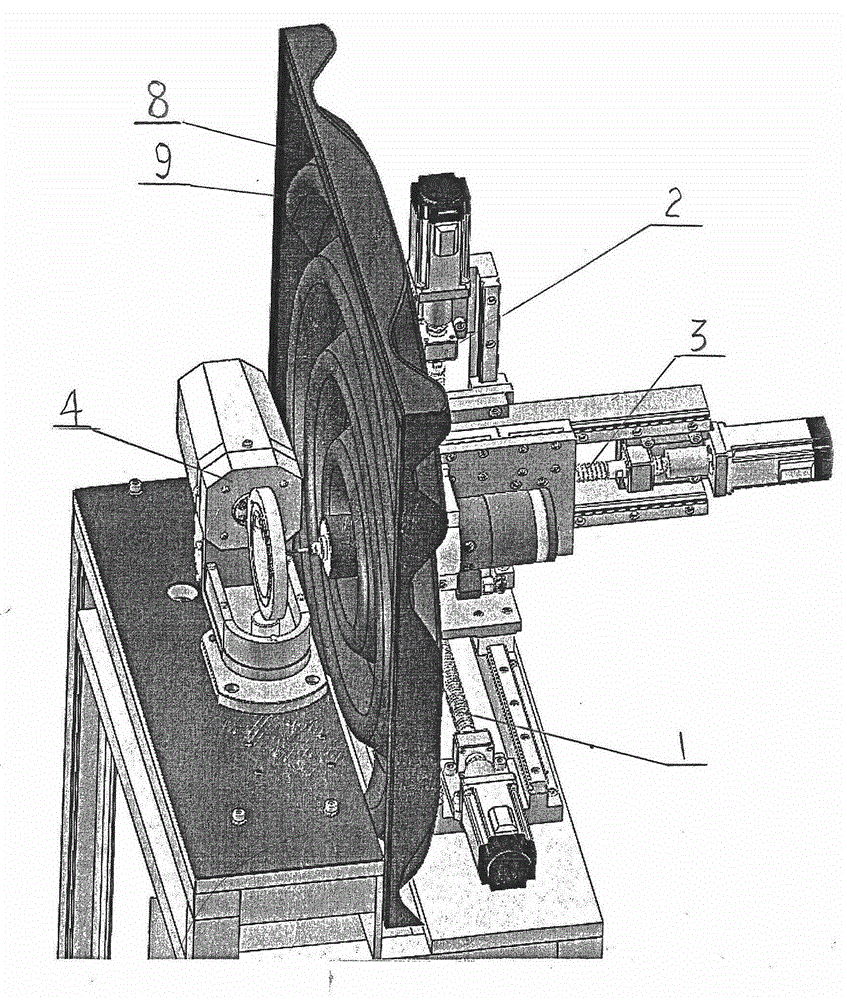

[0011] Machine tool processed by the present invention Figure 1 to Figure 5 Provided embodiment, because the processed workpiece blank block is circular, the workpiece is installed in the workpiece holder (7), and the engraving spindle (6) is installed on the (3) axis and parallel to the (3) axis, through (1) , (2) and (3) the three linear axes drive the cutting motion of the workpiece in the three coordinate directions of the spindle, and the two-axis rotation axis of (4) and (5) makes the swing of the workpiece in two directions meet the swing required for cutting . On the premise of satisfying the five-axis movement, the protection of the three linear axes (1), (2) and (3) through the partition (8) of elastic material and the protection of the (4) axis by the protective cover (11) meet the requirements of the machine tool. The overall protection requirements for the transmission part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com