Milling processing technology of solid solution steel double-gooseneck hinge

A milling and gooseneck technology, applied in the direction of pivot connection, can solve the problem of not being able to meet the requirements of the coaxiality and position of the lug, improve the shape and position tolerance, improve the processing efficiency, and meet the assembly requirements. The effect of hole position accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, the present invention will be further described:

[0030] See attached figure 1 to attach Figure 7 , a solid solution steel double gooseneck hinge milling process, comprising the following steps:

[0031] Step 1: blanking, heat treatment, heating to 552 degrees Celsius, after heating for 4 hours, air cooling.

[0032] as attached figure 1 As shown, blanking, the tolerance of length and width is 0~±5mm, and the precipitation hardening stainless steel is heat treated.

[0033] Step 2: Mill the hexagonal blank, drill and ream the technological hole, and accurately clamp.

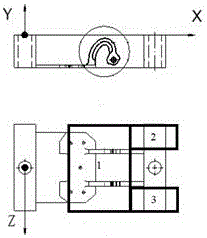

[0034] as attached figure 2 As shown, the blank is milled hexagonally to ensure that the flatness of the two major planes is 0.1, and that the parallelism with the bottom surface of the base is 0.1.

[0035] as attached figure 2 As shown, drill and ream the process hole, and ensure the verticality with the ground 0.05; precise clamping.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com