Device for eliminating mounting error of floating sealing ring

An installation error and floating seal ring technology is applied in the field of devices for eliminating the installation error of the floating seal ring, and can solve the problems of increasing the number of replacements and manual labor, deviating from the original position of the floating seal ring, increasing the friction force of the floating seal ring, etc. Achieve the effect of saving manual installation time, reducing frictional force increase, and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

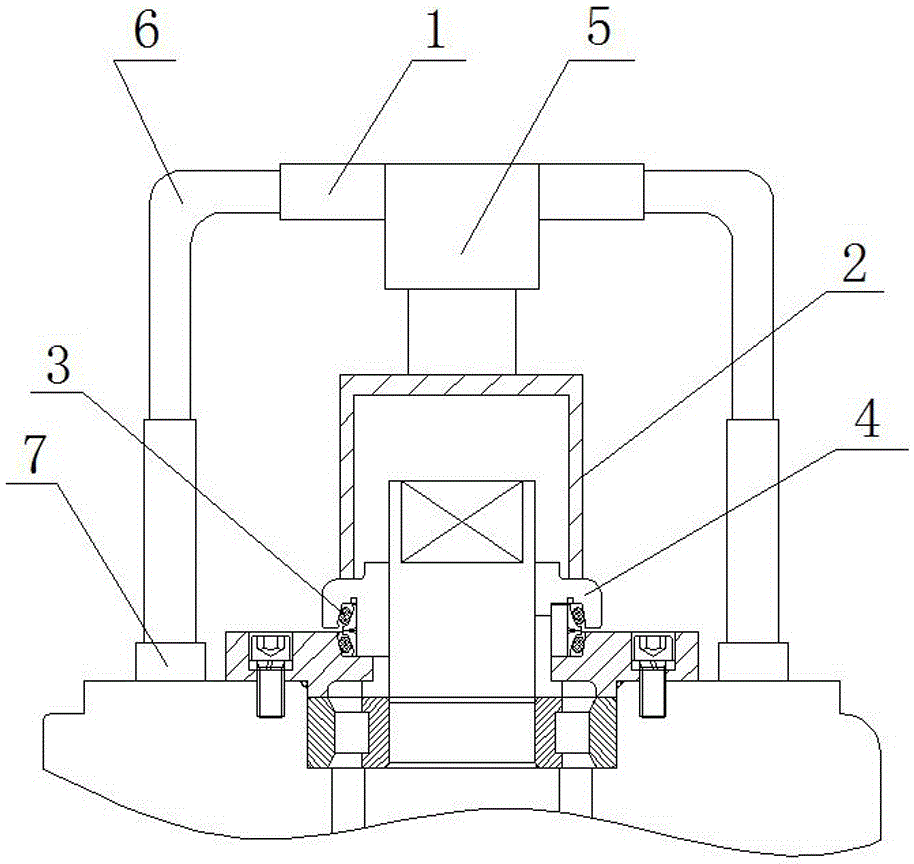

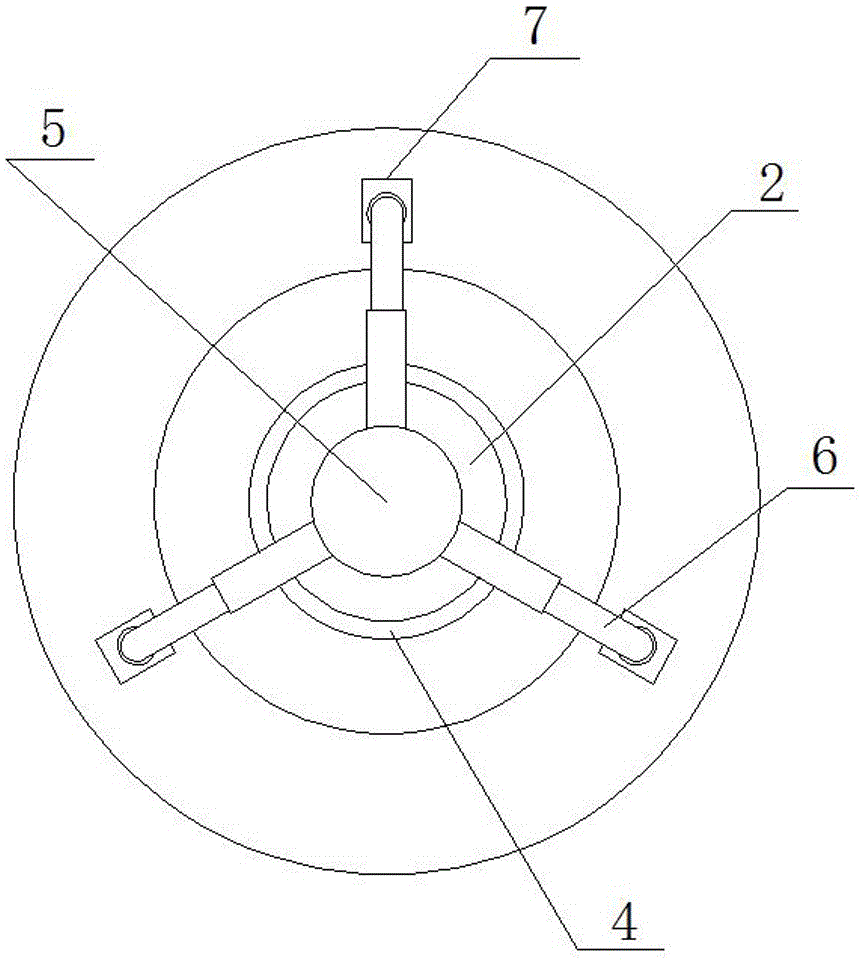

[0021] Such as figure 1 and figure 2 As shown, the device for eliminating the installation error of the floating seal ring in the present invention includes a pressure applying device 1, a lower pressure body 2 and a floating seal ring 3, an end cover 4 is arranged above the floating seal ring 3, and the lower pressure body 2 is Hollow structure, the lower pressing body 2 is located on the upper surface of the end cover 4 of the floating seal ring 3 to be installed, and the pressure applying device 1 is located on the upper surface of the lower pressing body 2 and provides the lower pressing body 2 with the pressure to the end cover 4 pressure, the pressurizing device 1 includes a pressurizing cylinder 5 and a positioning leg 6, the telescoping end of the pressurizing cylinder 5 is located on the lower pressing body 2, and the positioning leg 6 is arranged on the outer surface of the positioning end of the pressurizing cylinder 5, The lower end of the positioning leg 6 is pr...

Embodiment 2

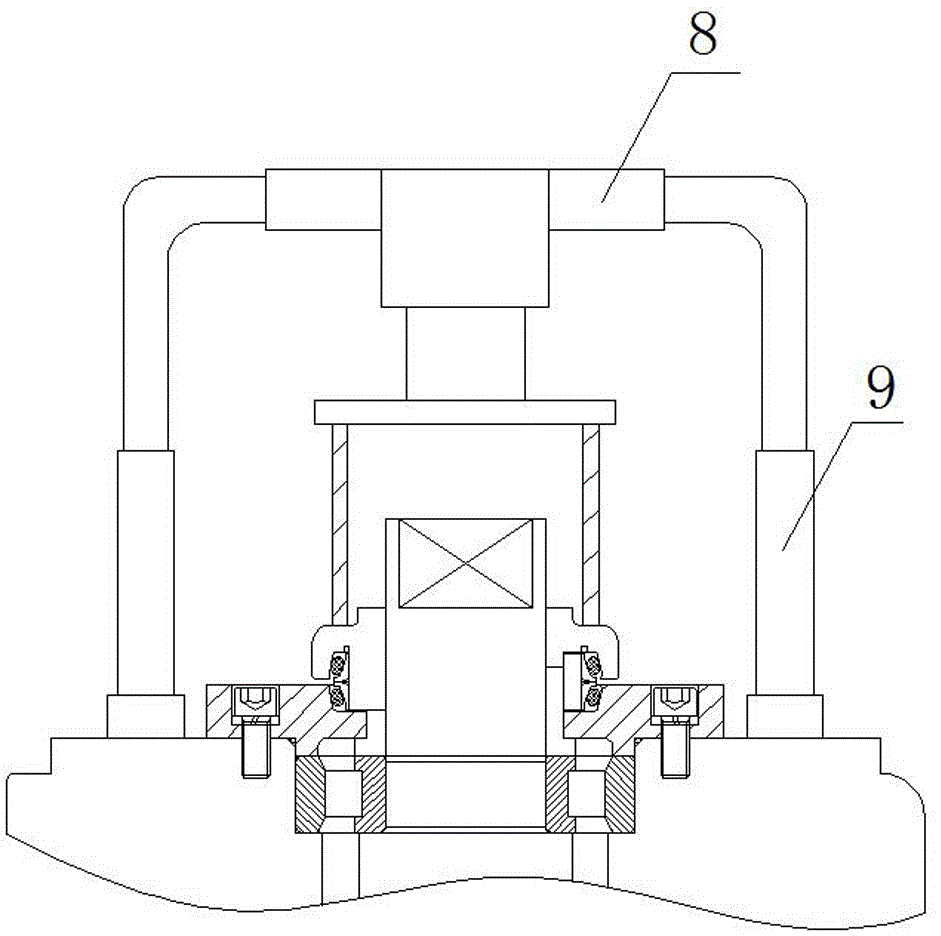

[0030] Such as image 3 As shown, when the diameter of the floating seal ring 3 is large, a larger-diameter lower pressure body 2 is needed. At this time, the tubular lower pressure body 2 can save material and is easier to obtain. At this time, due to the pressure cylinder 5 Due to the limited diameter, it is necessary to add cover plates on the lower surface of the pressurizing cylinder 5 and the upper surface of the lower pressure body 2, so that the pressure applying device 1 can adapt to the floating seal rings 3 of various sizes.

[0031] Other structures, component functions and working methods of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com