Full-automatic vegetable slicing and shredding device

A fully automatic and vegetable technology, applied in metal processing and other directions, can solve problems such as laborious, low efficiency, and poor slicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

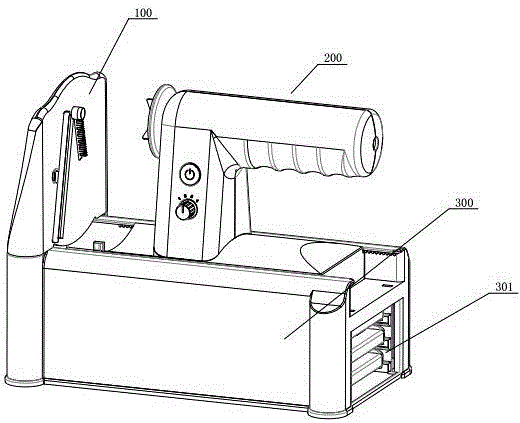

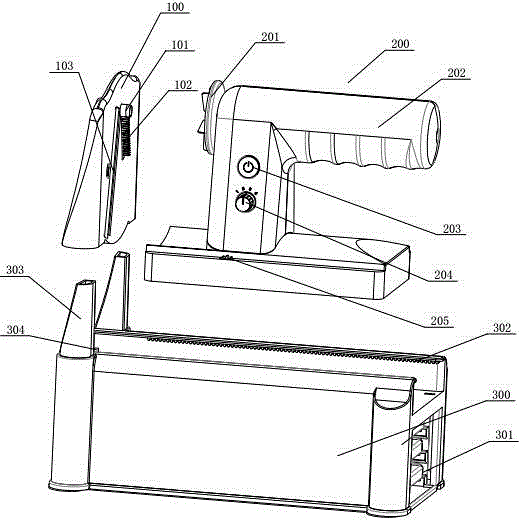

[0023] Such as figure 1 , figure 2 As shown, the present invention is a fully automatic vegetable slicing and shredding device, which includes a base 300, a track is arranged above the base 300, a body 200 is movably installed on the track, and two columns 303 are arranged at the end of the track. The knife door 100 is set on the above-mentioned column 303 . Therefore, both the machine body 200 and the knife door 100 can be freely separated from the base 300, which is convenient for cleaning.

[0024] Such as image 3 As shown, the knife door 100 is provided with a positioning knife 101 and a slicing knife 103, the positioning knife 101 is in the shape of a hollow tube, and the positioning knife 101 and the positioning disc 201 are on the same axis. When the vegetable is sliced or shredded, the vegetable will always rotate around the axis of the positioning knife 101 without shaking, and when slicing or shredding, an inner core of the vegetable will pass through the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com