Tipping paper printing device and tipping paper printing method

A technology of printing device and printing method, applied in printing, printing machine, rotary printing machine, etc., to achieve good water content, reduce or eliminate swelling phenomenon, and good printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

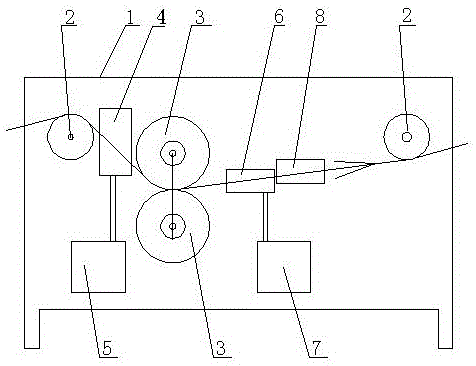

Method used

Image

Examples

Embodiment 1

[0022] The tipping paper is not fumigated, and the ink is directly printed on the tipping paper.

[0023] The tipping paper produced in this way has a certain swelling phenomenon when observed under a microscope.

Embodiment 2

[0025] The tipping paper is fumigated with ethanol steam, the fumigation time is 60-100 seconds, the temperature is 70-80 ℃, and then the ink is printed on the tipping paper.

[0026] The tipping paper produced in this way is observed under a microscope, and a certain swelling phenomenon is reduced or disappeared.

Embodiment 3

[0028] After printing, the product in the above embodiment 2 is fumigated with acetic acid vapor, and the time used for fumigation is 60-100 seconds and the temperature is 70-80°C.

[0029] The harmful substances (phenols, benzene, etc.) in the tipping paper produced in this way are reduced, which is more beneficial to the health of users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com