Metal frame for supporting spherically-distributed large-aperture optical components

A metal frame and optical element technology, applied in the direction of optical elements, optics, building components, etc., can solve problems such as the inability to meet the stable support requirements of dense large-diameter optical elements, meet the requirements of installation and positioning and space layout adjustment, and improve The effect of structural stability and large span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

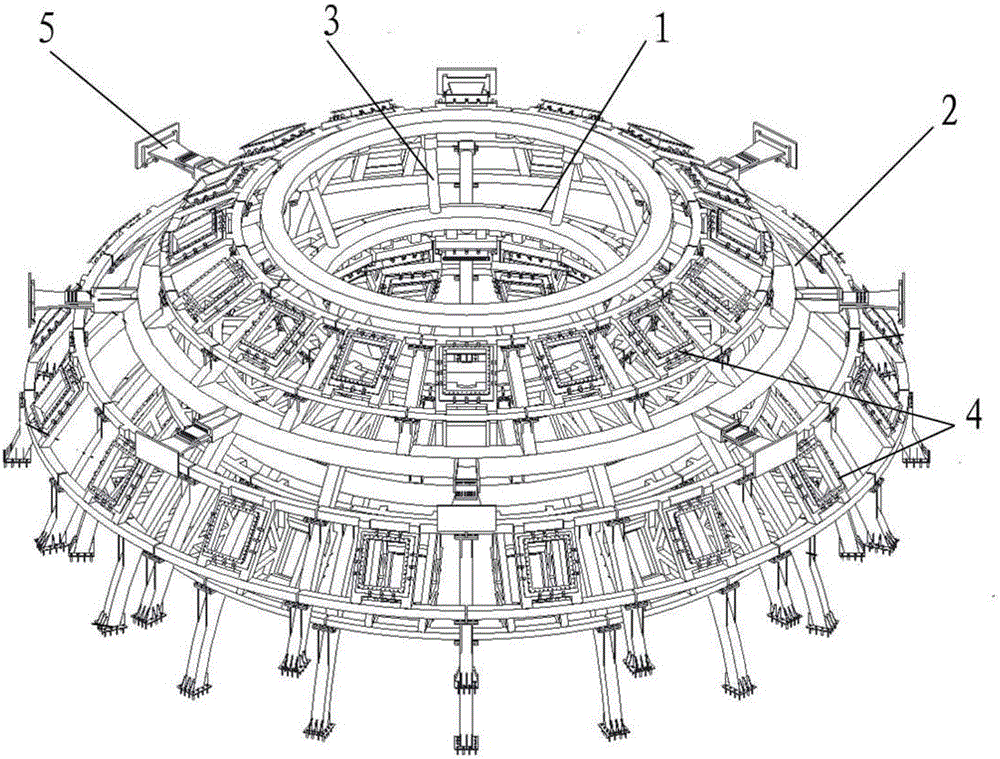

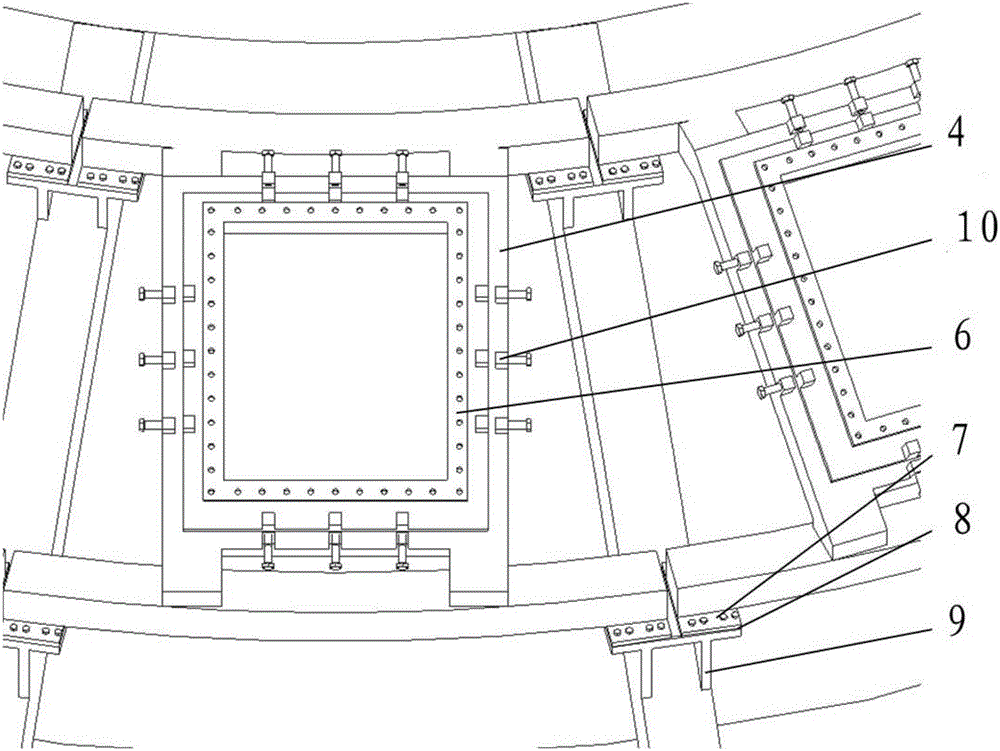

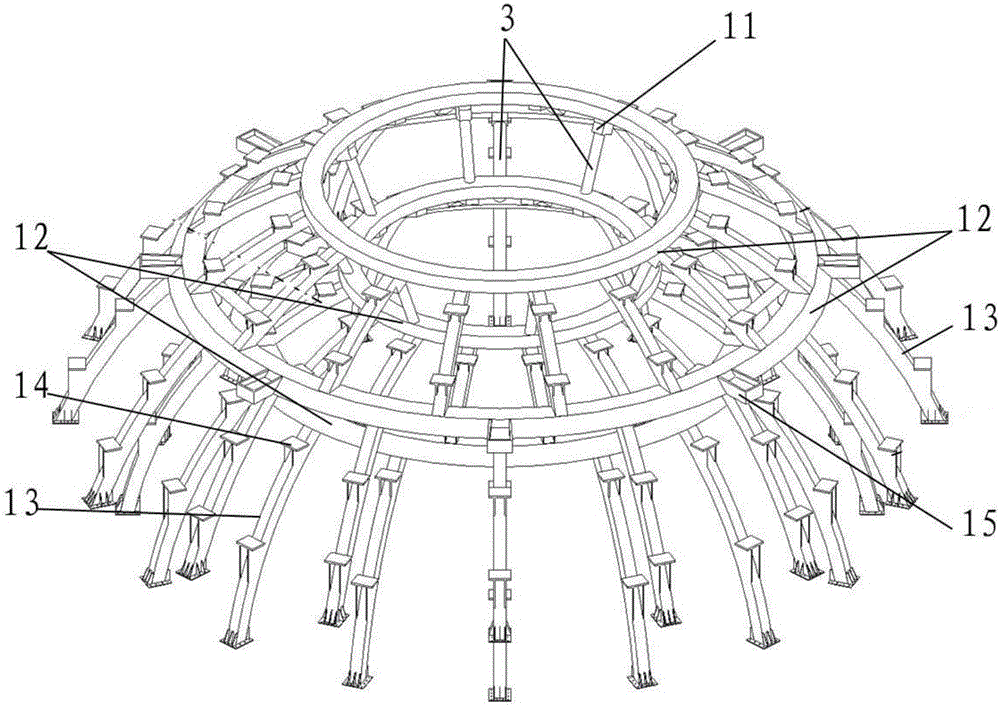

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown, the present invention comprises double-deck dome-type metal frame, and double-deck dome-type metal frame comprises the inner layer metal frame 1 of dome-type structure and the outer layer metal frame 2 of dome-type structure, and the spherical geometric center of double-deck dome-type metal frame It coincides with the focusing center of the laser beam of the ICF device within a certain accuracy range. The inner metal frame 1 and the outer metal frame 2 are rigidly connected as a whole through several inter-frame connecting rods 3 . Both the inner metal frame 1 and the outer metal frame 2 are welded by several arc-shaped columns 13 and two upper and lower ring-shaped beams 12 parallel to each other. Its cross-sectional shape can be optimized according to the results of mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com