Hot-rolled high-precision full-thread reinforcing steel bar for building

A full-thread, high-precision technology, used in buildings, building components, building reinforcements, etc., can solve problems such as poor connection strength, poor mechanical properties, and low precision, and achieve the effects of reducing production costs, easy processing, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

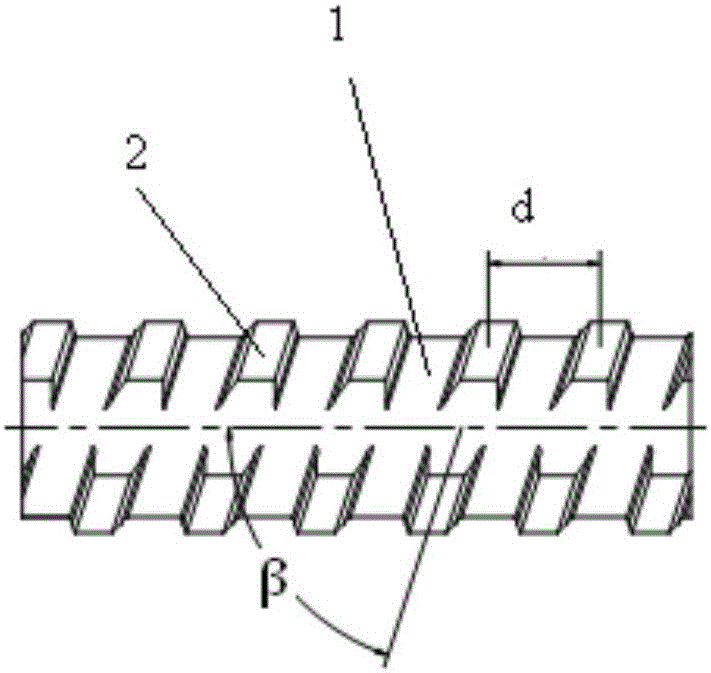

[0024] Such as figure 1 As shown, the fully threaded steel bar is a 500Mpa steel bar, and the transverse rib 2 is a unidirectional left-handed spiral. The root chamfer r1 of the transverse rib 2 is 0.9mm, and the top chamfer r2 is 0.4m.

[0025] The distance d between the transverse ribs 2 is 10mm.

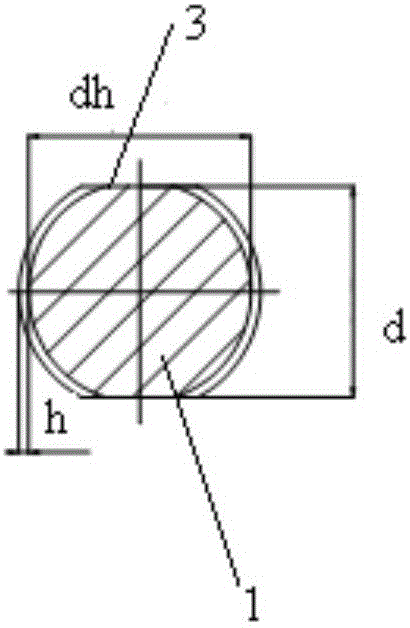

[0026] Such as Figure 4 As shown, the height h of the transverse rib 2 is 1.5 mm and the bottom width b is 5.6 mm.

[0027] Such as Figure 4 As shown, the angle α between the side of the transverse rib 2 and the outer circumferential surface of the rod body 1 is 60°; as figure 1 As shown, the angle β between the transverse rib 2 and the axis of the rod body 1 is 81.8°.

[0028] Such as image 3 As shown, the distance d between the free expansion surfaces of the fully threaded steel bars is 19.0 mm.

[0029] Such as image 3 As shown, the diameter dh of the rod body 1 is Φ20.

[0030] Such as image 3 and 4 As shown, the section of the transverse rib 2 is an isosceles ...

Embodiment 2

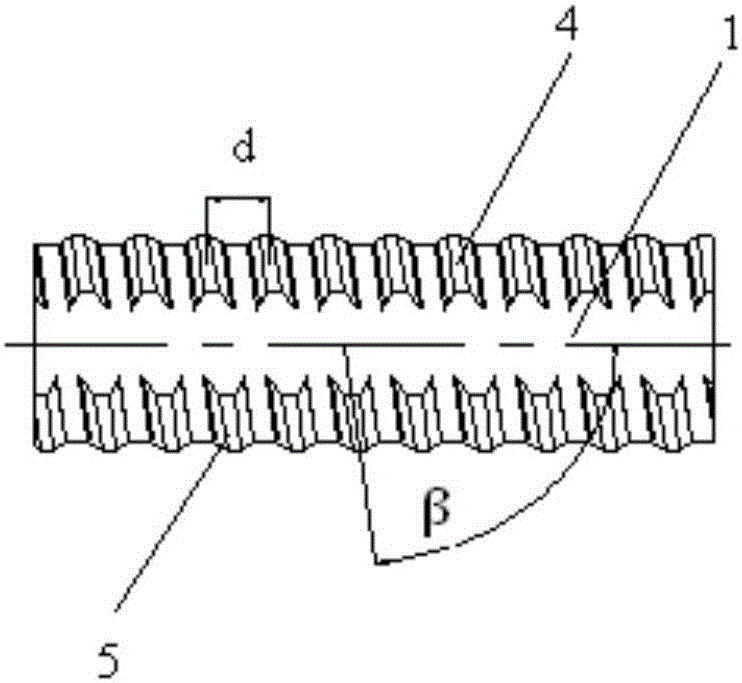

[0032] figure 2 As shown, the fully threaded steel bars are 500Mpa grade steel bars, and the equal-height spiral transverse ribs are unidirectional right-handed spirals. The root chamfer r1 of the transverse rib 2 is 1.5 mm, and the top chamfer r2 is 0.5 mm.

[0033] The distance d between the transverse ribs 2 is 6.0mm.

[0034] Such as Figure 4 As shown, the height h of the transverse rib 2 is 1.0 mm and the bottom width b is 4.0 mm.

[0035] Such as Figure 4 As shown, the angle α between the side of the transverse rib 2 and the outer circumferential surface of the rod body 1 is 45°; as figure 2 As shown, the angle β between the transverse rib 2 and the axis of the rod body 1 is 85.9°.

[0036] Such as image 3 As shown, the distance d between the free expansion surfaces of the fully threaded steel bars is 23.4 mm.

[0037] Such as image 3 As shown, the diameter dh of the rod body 1 is Φ25.

[0038] Such as image 3 and 4 As shown, the section of the transver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com