An automatic removal device and method for preventing iron impurities from entering a refiner

A technology of automatic cleaning and refining, which is applied in the direction of valve devices, chemical instruments and methods, sliding valves, etc., can solve the problems of equipment hazards, grinding teeth interrupted into pits, and filtration cannot be solved, so as to achieve simple operation and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

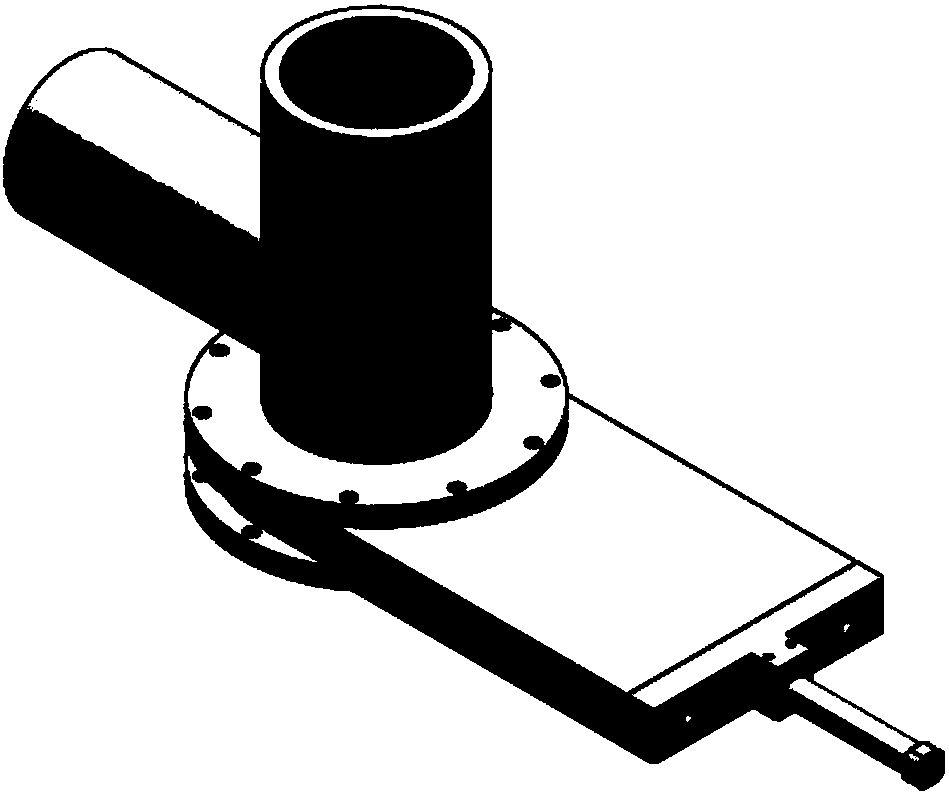

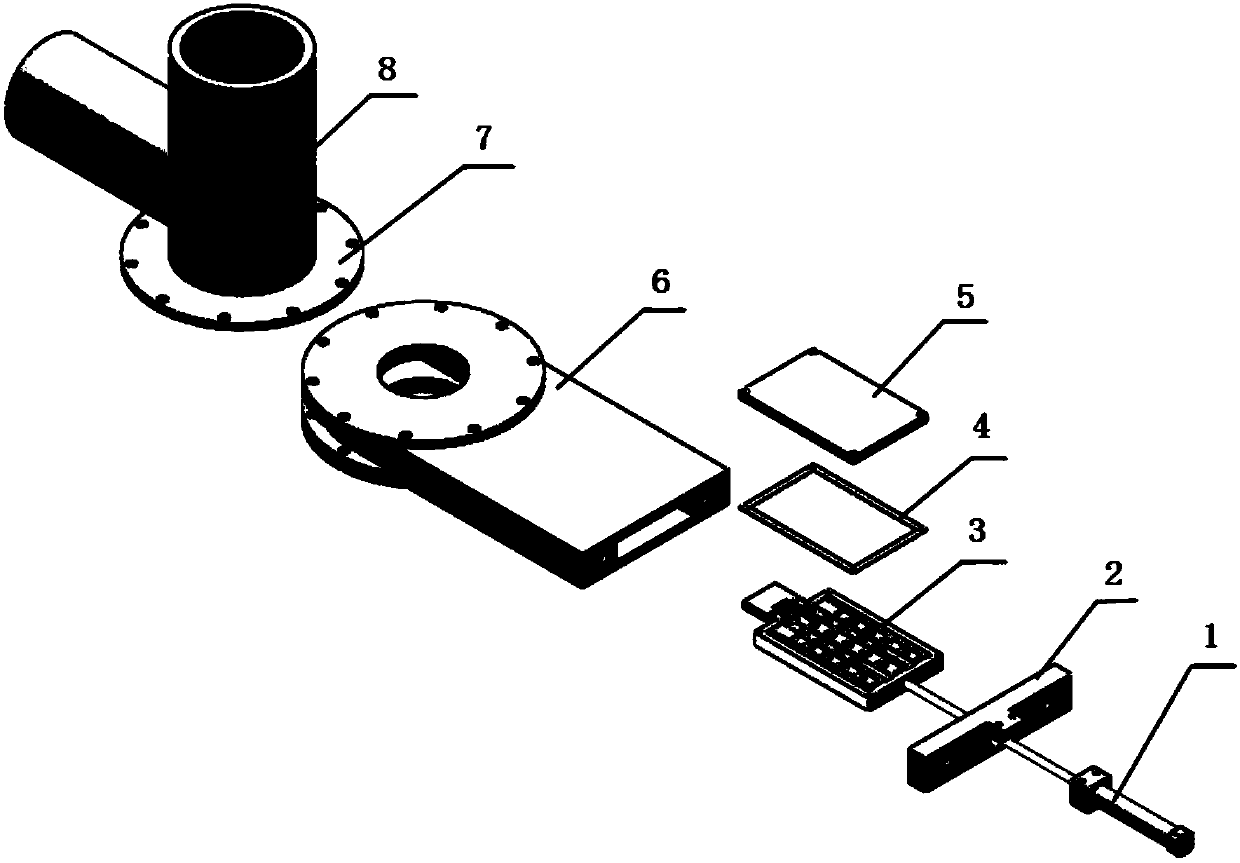

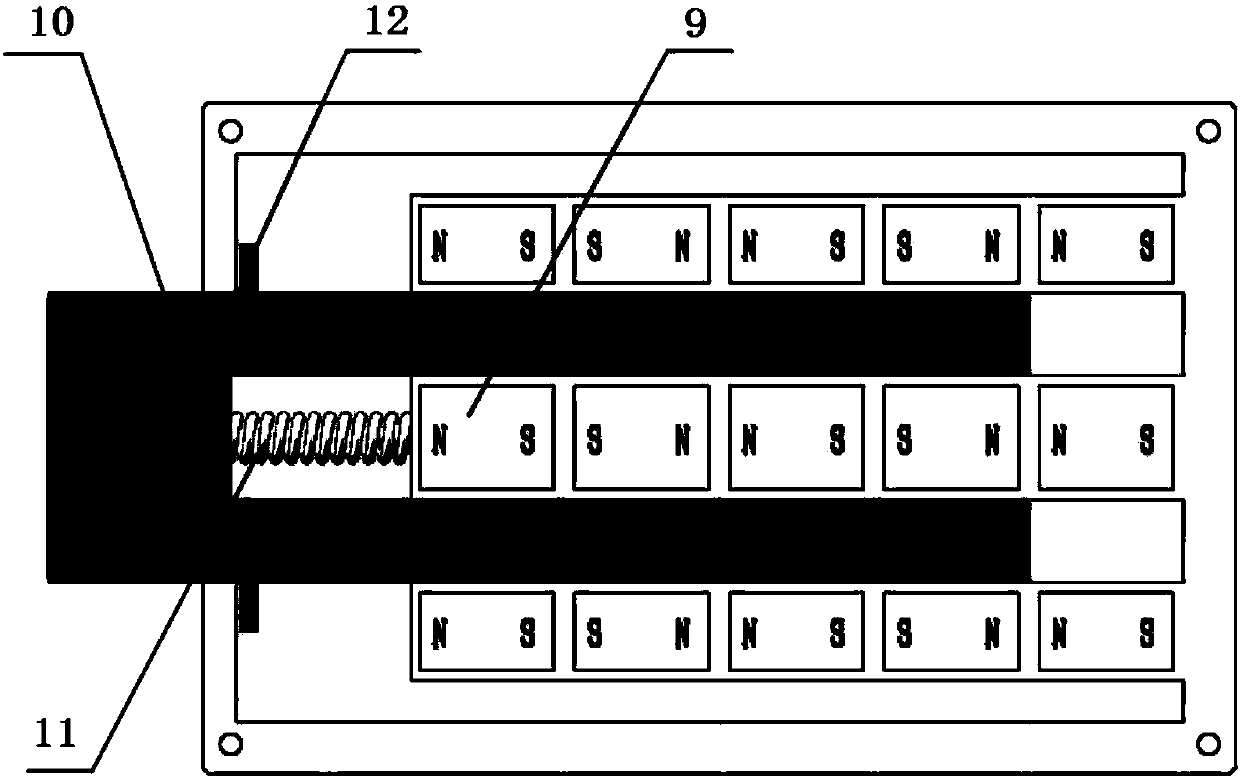

[0030] Such as figure 2 As shown, the device of the present invention includes an electric push rod 1, a push rod mounting plate 2, a core plate and a valve body 6, and the core plate includes a core plate main body 3, a sealing gasket 4 and a yoke 5; The yoke 5 mainly functions to conduct the magnetic circuit, and the sealing gasket 4 acts as a seal between the core plate main body 3 and the yoke 5 . The core plate is inserted into the valve body 6, the push rod mounting plate 2 is installed on the valve body 6, the electric push rod 1 is slidably installed on the push rod mounting plate 2, and the electric push rod 1 is fixedly connected with the core plate. Such as image 3 and 4 As shown, the core plate main body 3 includes a fixed magnetic system 9 and a moving magnetic system 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com