Vision auxiliary control method and device for wire arrangement consistency of optical fiber winding machine

An auxiliary control device and auxiliary control technology, applied in the field of optical fiber winding, can solve the problem of inability to automatically adjust the wire feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

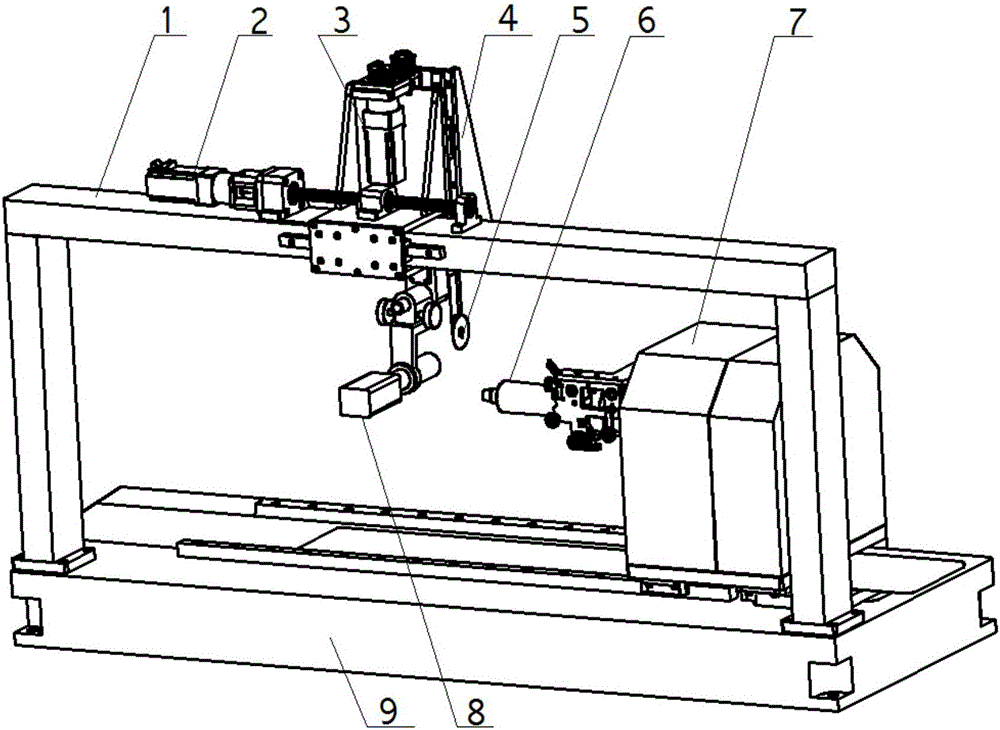

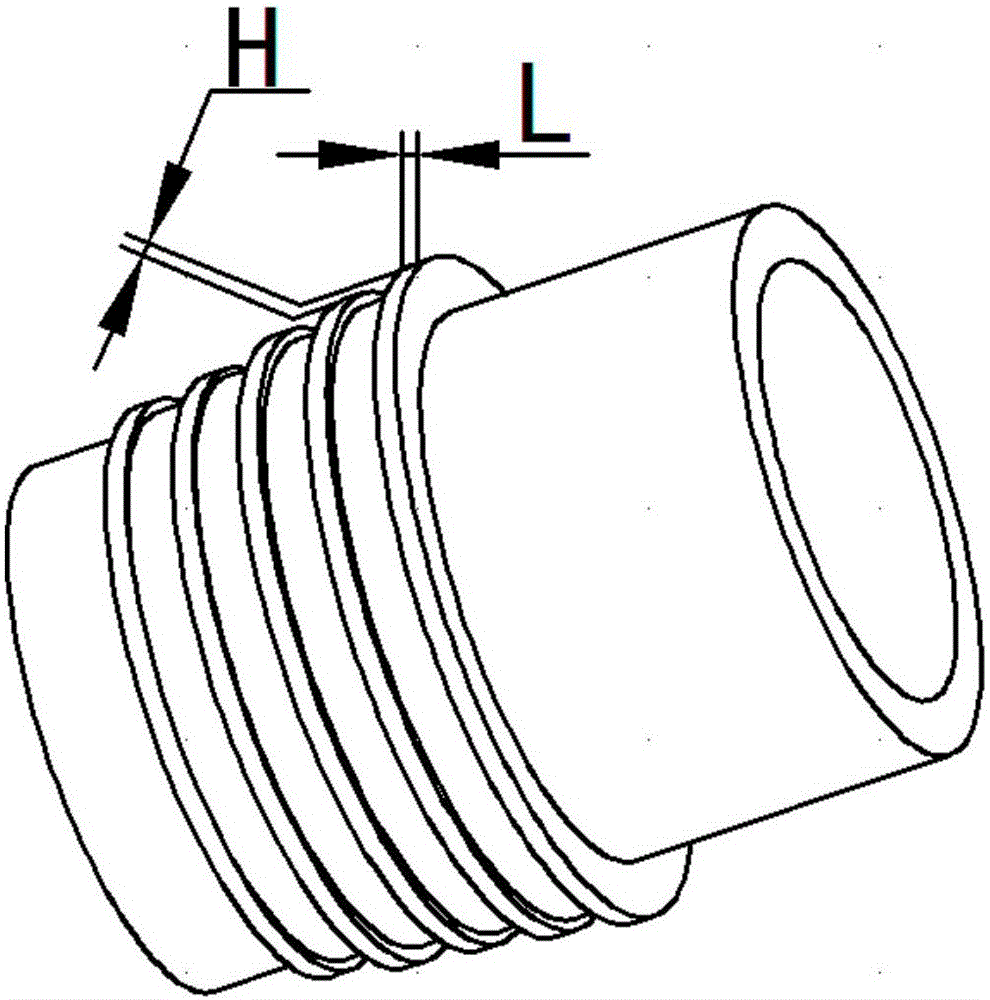

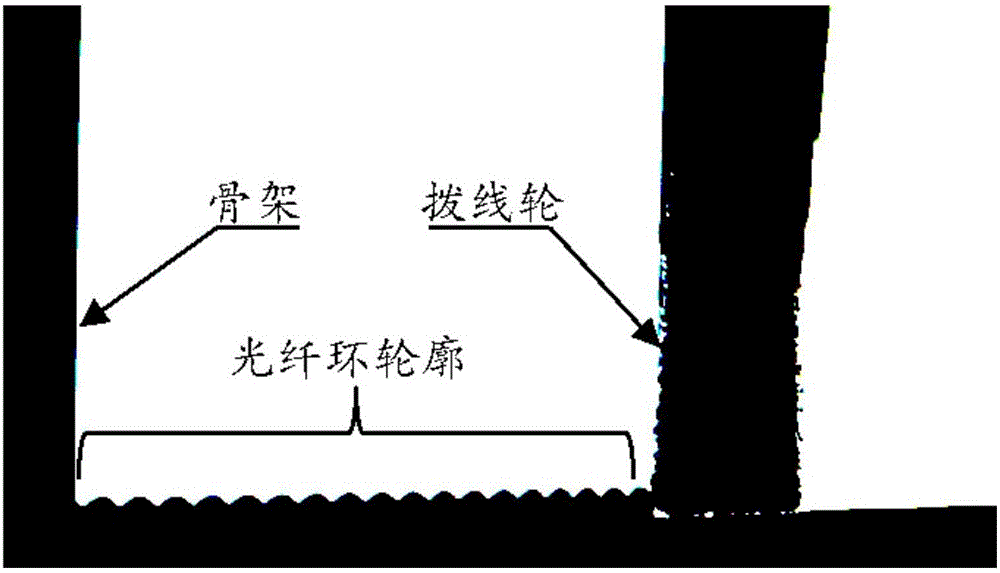

[0046] refer to figure 1 and figure 2 , the preferred embodiment of the present invention provides a visual aid control device for the alignment consistency of the optical fiber winding machine, including a machine base 9, a machine frame and a supporting beam 1, and a gear box arranged on the machine base 9 that can move left and right Body 7, the gear box body 7 is provided with a winding main shaft 6, the winding main shaft 6 can move left and right with the movement of the gear box body 7, and it drives the reducer through the first servo motor in the gear box body 7 to generate rotation movement to take up the line; the support beam 1 is provided with a bracket 4 that can move left and right and up and down, and the bracket 4 is fixed with a relatively static dial wheel 5 and a camera 8, and the lens position of the camera 8 is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com