Bubble suppression method and device of large-scale transformer during live-line oil filtering

An oil filtering device and transformer oil technology, which is applied in the direction of transformer/inductor cooling, foam dispersion/prevention, etc., can solve problems such as unconsidered bubble suppression, achieve high-efficiency live oil filtering work, solve safety risks, and improve equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

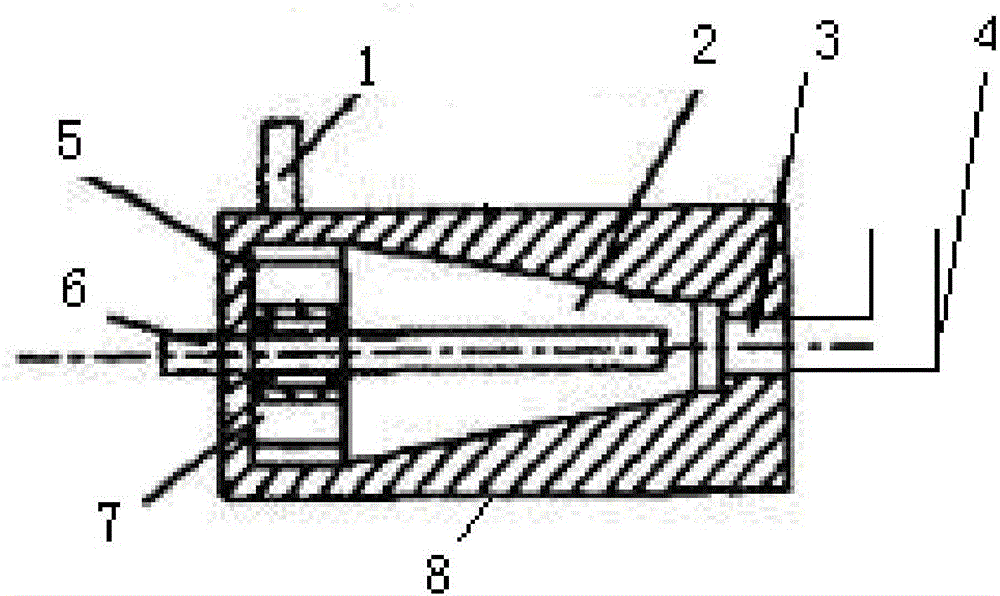

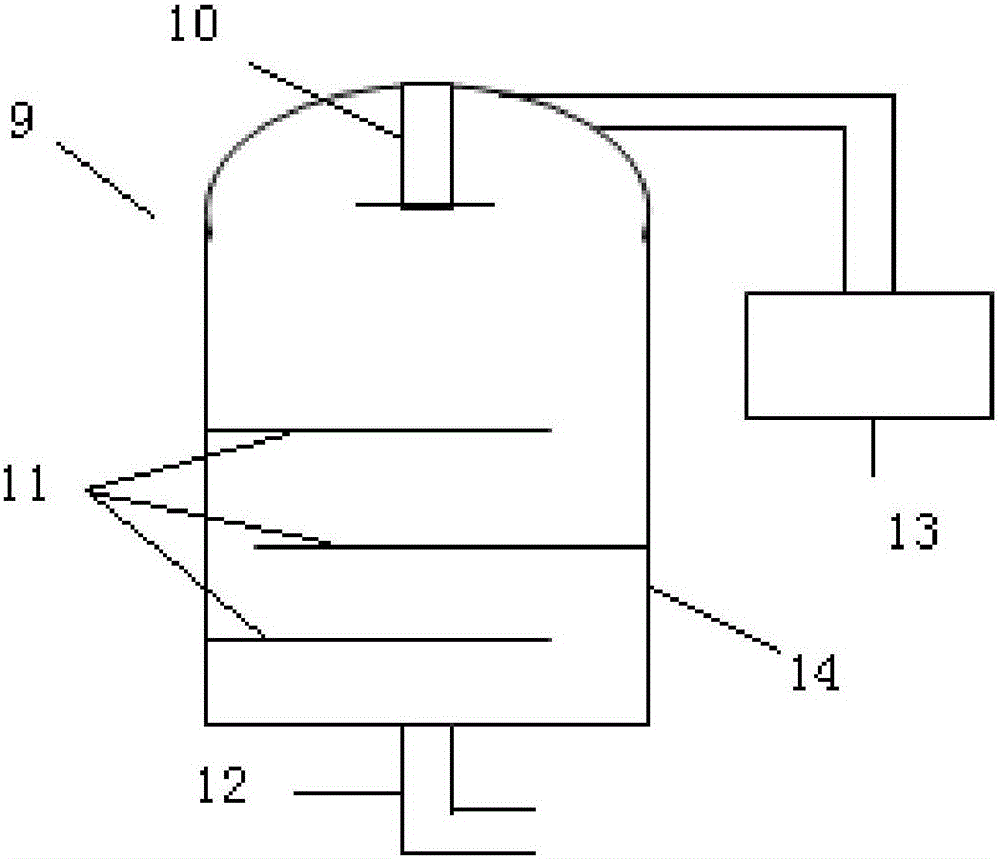

[0018] see figure 1 and figure 2 The method for suppressing air bubbles during live oil filtering of large transformers provided by the present invention comprises a transformer live oil filter device and live oil filter equipment thereof, and a vacuum air bubble elimination device 9 and a forced air bubble remover are connected in series in the transformer live oil filter device 8. The vacuum bubble elimination device 9 uses a vacuum pump to evacuate the pair, and the vacuum degree reaches 5-150 Pa; the flow rate of the transformer oil is controlled at 30-150 L / min.

[0019] see figure 1 and figure 2 The device provided by the present invention to realize the method for suppressing air bubbles during live oil filtering of a large transformer includes a live oil filter device for a transformer and live oil filter equipment thereof, a vacuum bubble elimination device 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com