Ball nut assembly for an electromechanically actuable parking brake assembly of a brake assembly

A ball nut and brake assembly technology, which is applied to brake actuators, brake action starting devices, brakes, etc., can solve problems such as limited packaging space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

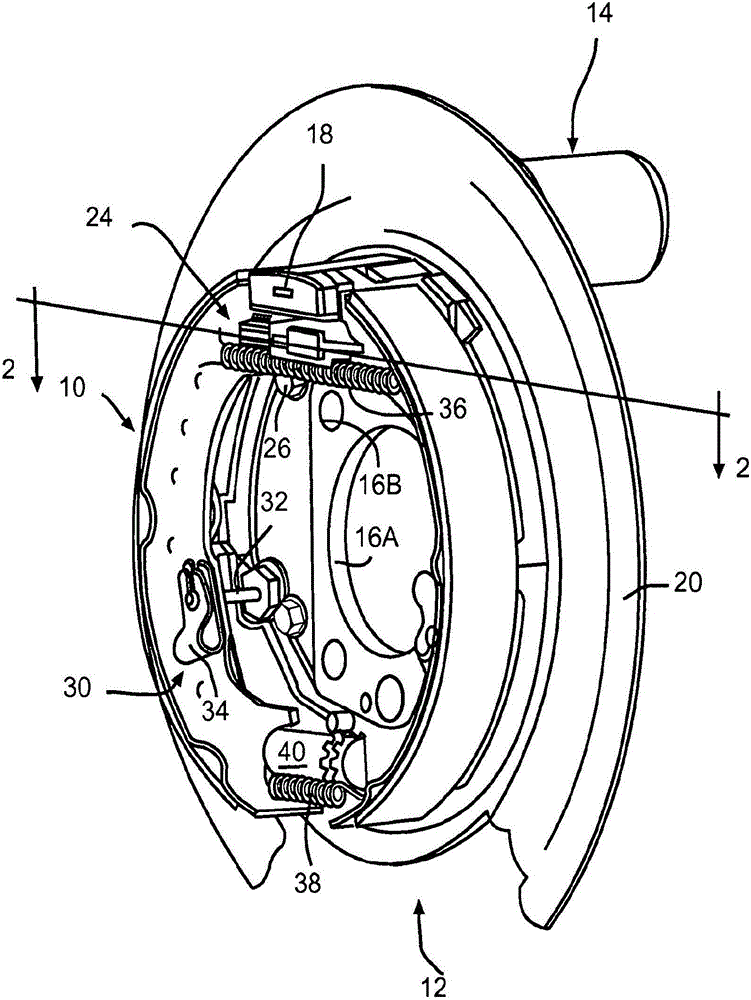

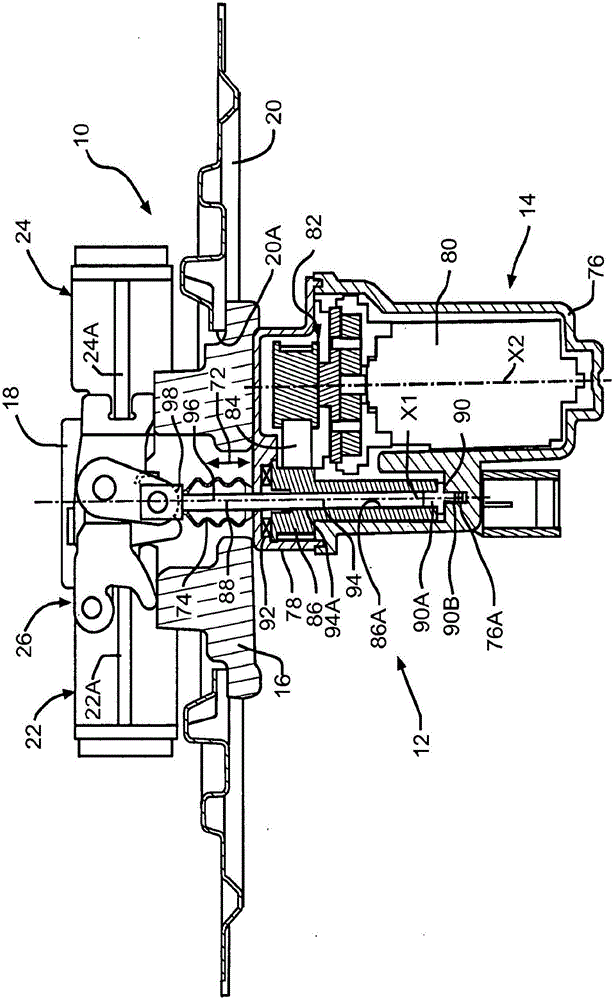

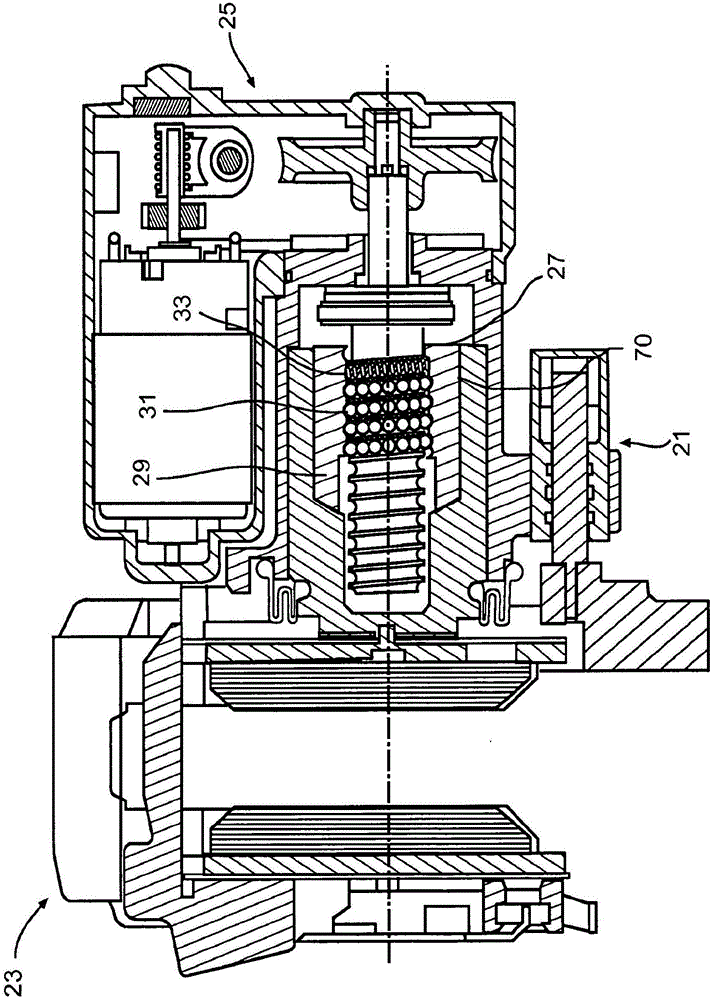

[0037] Referring now to FIGS. 1 and 2 , there is shown a prior art drum-in-disc parking and emergency brake 10 of a vehicle-drum-in-disc disc brake assembly, generally indicated at 12 . The actuating assembly has an electric actuator unit (generally indicated at 14) for actuating its drum-in-disc parking and emergency brake 10 (ie: parking brake). The general structure and operation of brake assembly 12 is conventional in the art, and may be generally similar to those described in U.S. Patent No. 5,322,145 to Evans, U.S. Patent No. 6,729,444 to Schmandt et al., and U.S. Patent No. 6,729,444 to Boyle et al. No. 8,011,482 of the type shown and described, the disclosures of which are hereby incorporated by reference in their entirety. While the present invention will describe and illustrate the particular brake assembly 12 disclosed herein, it will be understood that the present invention may be used with other drum-in-disc brake assemblies in relation to the parking and emergenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com