Heat preservation tunnel and heat preservation control method

A temperature control and tunnel technology, applied in the direction of temperature control, metal rolling, etc., can solve the problems of uncontrollable heat loss, seamless pipe can not meet performance requirements, can not meet temperature requirements, etc., to ensure the rolling process , The effect of improving the yield and improving the accuracy of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

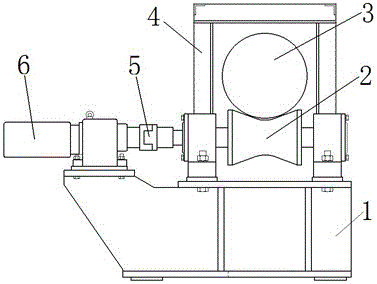

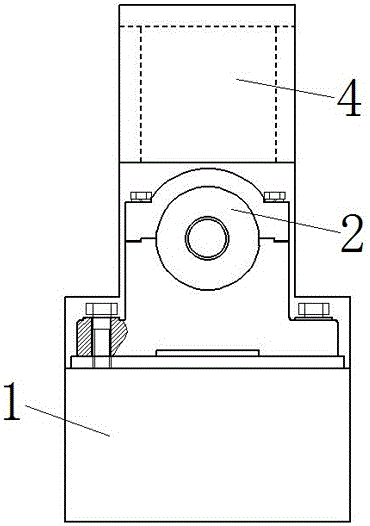

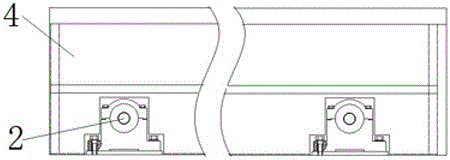

[0023] The embodiments of the present application will be described in detail below with reference to the accompanying drawings, but the present application can be implemented in a variety of different ways defined and covered by the claims. The drawings constituting a part of the application are used to provide a further understanding of the application, and the exemplary embodiments and descriptions of the application are used to explain the application, and do not constitute an improper limitation of the application.

[0024] The mobile smart temperature-controlled insulation tunnel is suitable for non-ferrous metals. The research and development is mainly aimed at the technological characteristics of titanium and titanium alloy materials. A series of titanium and titanium alloy seamless pipe products are TA1, TA2, TA3, TA4, TA5, TA6, TA7, TA8, TA8-1, TA9, TA9-1, TA10, TA13, TA15, TA18, TC1, TC2, TC3, TC4, TC10 and other materials. The product diameter specification is φ73-325...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com